Large-drift-diameter dry type quick connector

A large-diameter, dry-type technology, applied in the direction of mechanical equipment, couplings, etc., can solve the problems of impurities affecting the sealing performance, the flow area becomes smaller, and the leakage point is increased, so as to achieve smooth internal circulation, improve the flow coefficient, reduce the The effect of overall flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

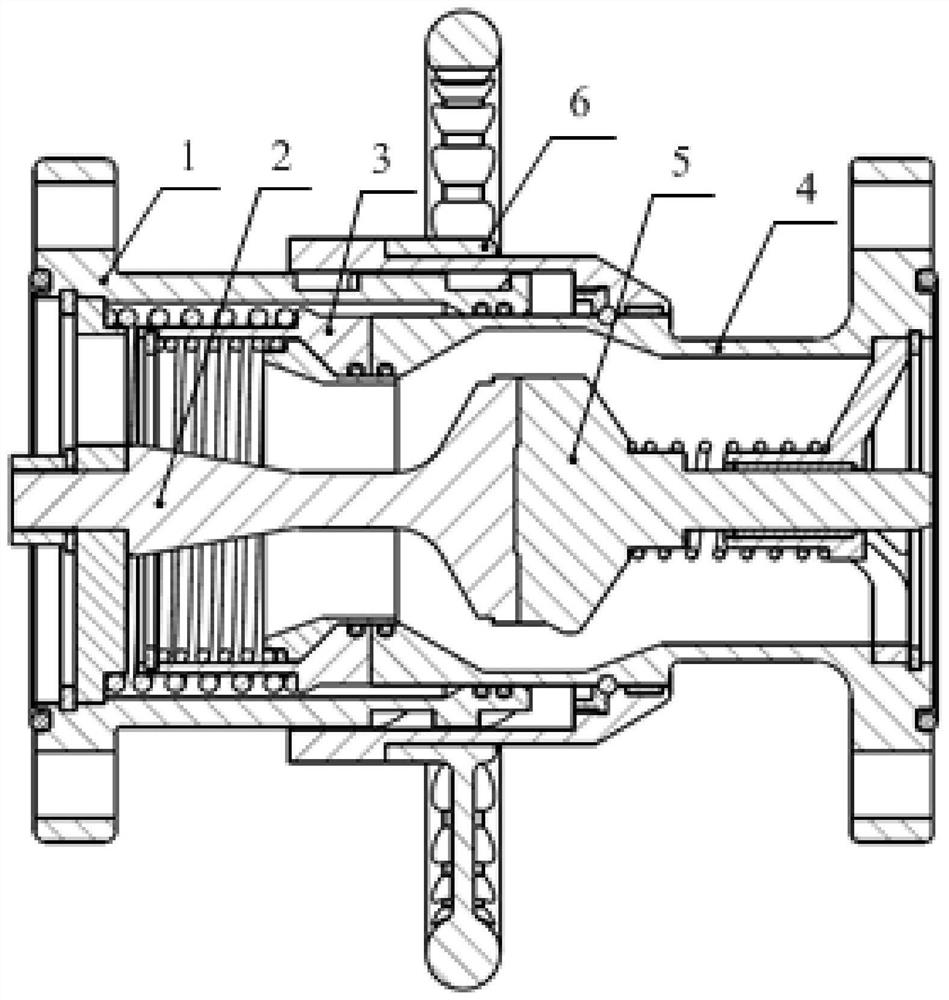

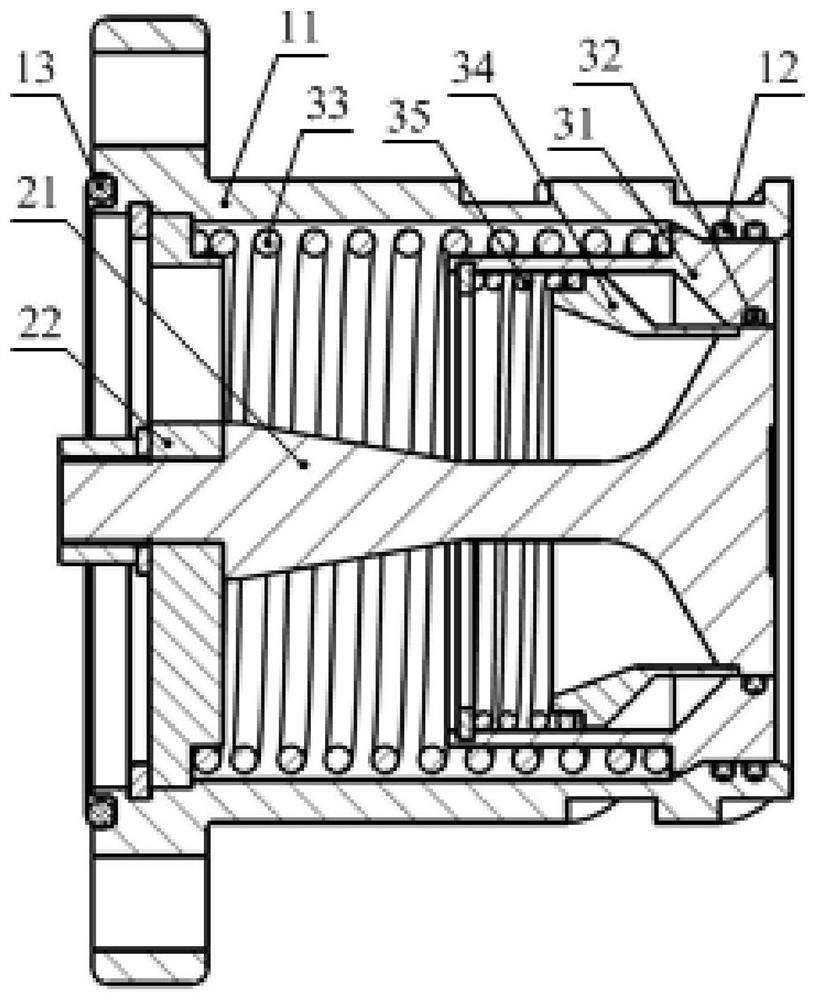

[0032] Such as Figure 1 to Figure 4 As shown, the present invention proposes a dry type quick joint with a large diameter, which includes a male joint (such as figure 2 ) and female connectors (such as image 3 ). Specifically, the male joint has a male joint housing assembly 1, a fixed valve core assembly 2, and a moving valve core assembly 3; the fixed valve core assembly 2 and the moving valve core assembly 3 form an the first channel of

[0033] The male joint housing assembly 1 includes the male joint housing 11, the male joint housing seal 12 and the outer seal 13 of the male joint; the outer housing 11 has a locking curved groove 111, and the inner cavity is provided with a fixed valve core assembly 2 and a movable The spool assembly 3; the fixed spool assembly 2 includes a fixed spool 21 and a fixed spool seat 22, and the rear part is fixed by a retaining ring; the movable spool assembly 3 includes a first movable spool 31, a first movable spool seal 32, the firs...

Embodiment 2

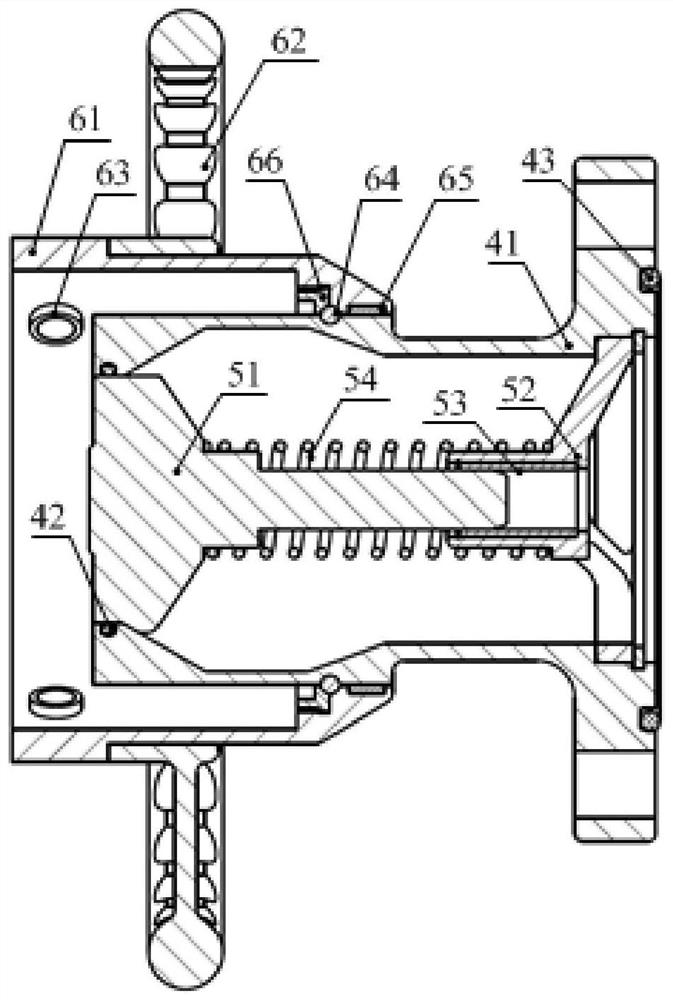

[0041] Such as Figure 1 to Figure 4 As shown, the male joint and the female joint rely on the sliding of the locking roller 63 on the female joint locking assembly 6 in the curved groove 111 on the male joint housing 11 to achieve docking and locking; the female joint locking assembly 6 passes through a set of circumferential steel Ball 64, guide ring 65 and steel ball fixing ring 66 realize the smooth rotation of operating hand wheel 62; guide ring 65 completes the circumferential direction support of the locking assembly, and steel ball fixing ring 66 compresses steel ball 64 in the circular groove to prevent steel ball The ball 64 comes out;

[0042] Other structures are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0044] Such as Figure 4 As shown, the male connector housing 11 is provided with a male connector housing locking curved groove 111 for locking the male connector and the female connector, which is used to constrain the movement track of the locking roller 63 and realize the docking of the male connector and the female connector; the male connector The locking curve groove 111 of the joint housing is a multi-segment curve, and the curve can be expanded into a horizontal line segment, a multi-segment obliquely downward straight line segment, a multi-segment obliquely upward straight line segment and a vertical line segment, or other types of curve segments in the same direction;

[0045] Other structures are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com