Non-positive displacement type pump and liquid supply device

A positive displacement pump and pump housing technology, which is applied to non-volume pumps, non-variable volume pumps, liquid fuel feeders, etc. Increased discharge flow and other issues, to achieve the effect of reducing noise and suppressing decompression boiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, embodiments of the present invention will be described based on the drawings.

[0035] (liquid supply device)

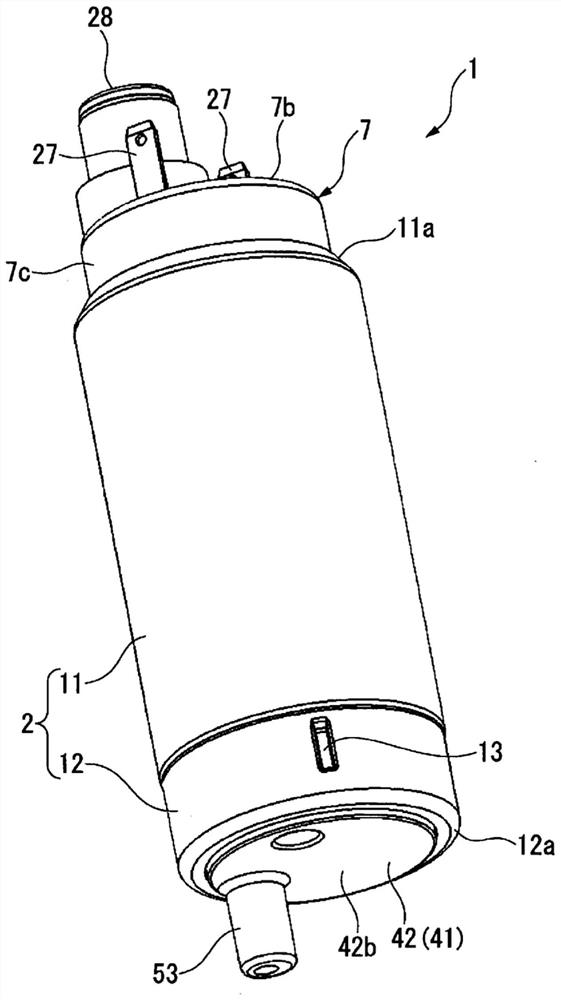

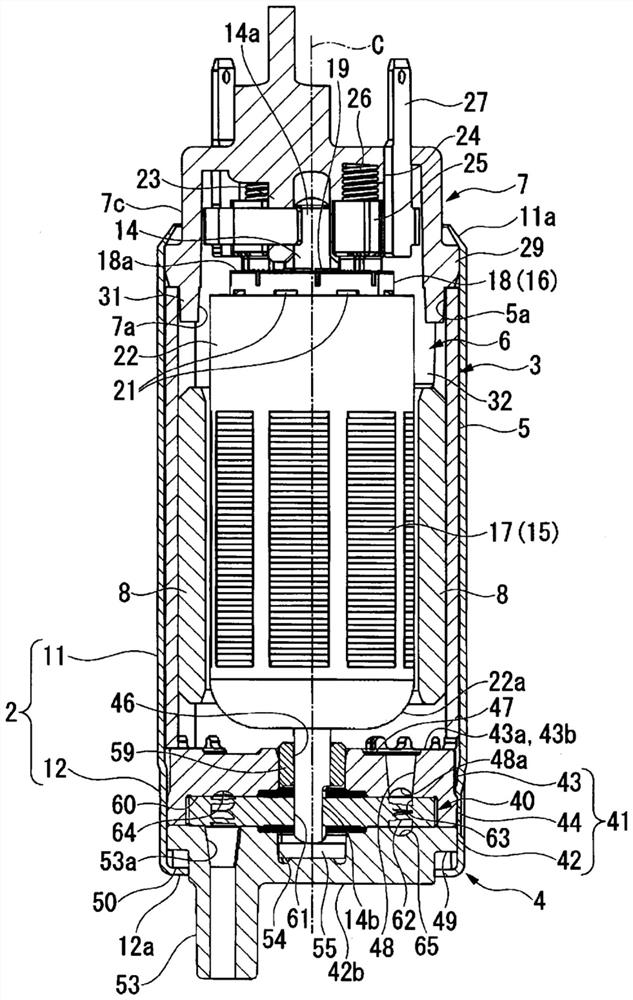

[0036] figure 1 It is a perspective view of the liquid supply device 1 . figure 2 is an axial sectional view of the liquid supply device 1 .

[0037] The liquid supply device 1 is used as a fuel pump for vehicles such as motorcycles and four-wheel vehicles. The liquid supply device 1 is a so-called in-tank type fuel pump arranged in a fuel tank not shown.

[0038] Such as figure 1 , figure 2 As shown, the liquid supply device 1 includes: a substantially cylindrical metal housing 2; The housing 2, the motor unit 3, and the pump unit 4 are arranged coaxially.

[0039] In the liquid supply device 1 , the pump unit 4 is used downward in the direction of gravity. Therefore, in the following description, the motor part 3 side may be referred to as the upper side, and the pump part 4 side may be referred to as the lower side. In addition, in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com