Refrigerator and manufacturing method

A manufacturing method and technology of refrigerators, which are applied to household refrigerators, household refrigeration devices, lighting and heating equipment, etc., which can solve the problem of decreased heat insulation, expanding the space of inner boxes and protective shells, and inability to obtain sufficient heat insulation, etc. problem, to achieve the effect of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

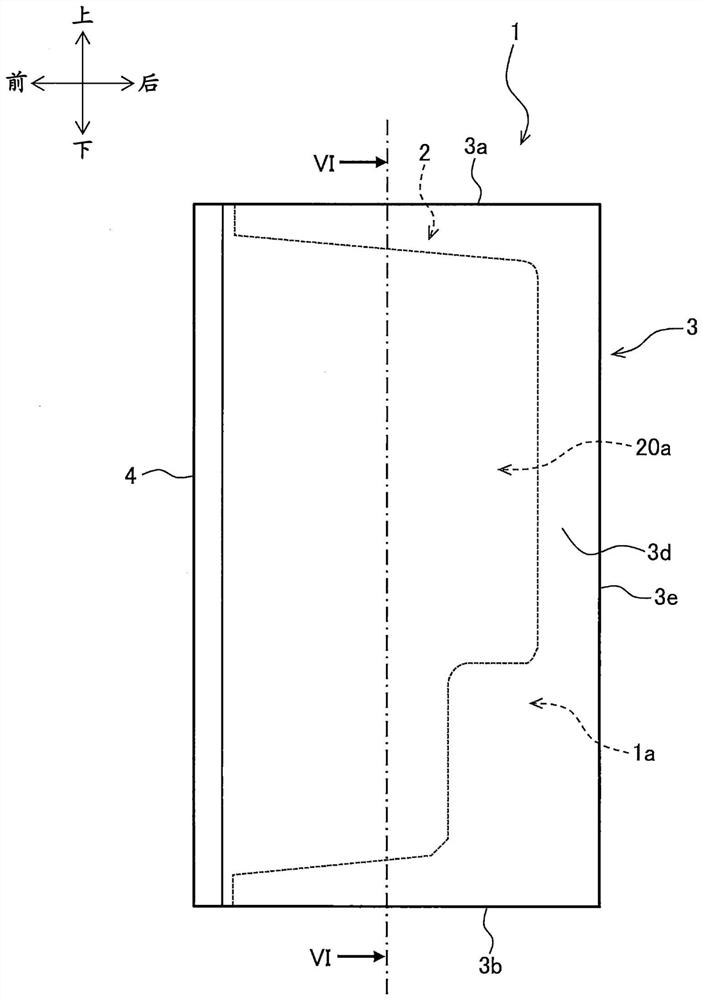

[0069] refer to Figure 8 The refrigerator of 2nd Embodiment is demonstrated. Figure 8 is equivalent to the above Figure 4A A schematic enlarged cross-sectional view of a schematic enlarged cross-sectional view of . This embodiment differs from the above-mentioned first embodiment in that the heat insulating foam 10B is attached to the inner box 2 via the heat insulating foams 18g covering both ends of the vacuum heat insulating material 11 .

[0070] like Figure 8As shown, the foam heat insulation protection material 10B on the right includes a vacuum heat insulation material 11, a foam heat insulation material 18f covering the rear end portion 11f of the vacuum heat insulation material 11, and a foam heat insulation material 18f covering the front end portion 11g of the vacuum heat insulation material 11. Foam insulation material 11g. Each foam heat insulating material 18f, 18g is foam-molded in advance, and the edge part with the inner box 2 is sealed with the adhesi...

no. 3 approach

[0081] refer to Figure 9 The refrigerator of 3rd Embodiment is demonstrated. Figure 9 is equivalent to the above Figure 4A A schematic enlarged cross-sectional view of a schematic enlarged cross-sectional view of . This embodiment differs from the above-mentioned second embodiment in that both end portions of the vacuum heat insulating material 11 are attached to the inner box 2 via the adhesive portion 17 . Moreover, at least a part (upper part, a lower part, etc.) of the vacuum heat insulating material 11 is attached to the inner box 2 via the foam heat insulating material 12 which is not shown in figure.

[0082] As the adhesive portion 17, an adhesive method such as polyurethane foam, hot melt, or double-sided tape can be employed. In this embodiment, the corner portion 2 of the inner box 2, the rear end portion 11f of the right vacuum heat insulating material 11 and the right end portion 11e of the rear vacuum heat insulating material 11 are attached to the inner bo...

no. 4 approach

[0092] refer to Figures 11A-11D The refrigerator of 4th Embodiment is demonstrated. Figure 11A It is the equivalent of the refrigerator of the fourth embodiment of the present invention Image 6 A schematic sectional view of a schematic sectional view of . This embodiment differs from the above-mentioned first to third embodiments in that a groove portion 10k is provided in the lower foam heat insulating material 10A and the upper foam heat insulating material 10C, and left and right vacuum insulation materials are assembled. Thermal Materials11.

[0093] like Figure 11A As shown, the vacuum heat insulation material 11 of the foam heat insulation protection material 10A of the lower side is located in an upper part, and the foam heat insulation material 12 covers the lower side. The lower plate 2 b of the inner box 2 is in contact with the vacuum heat insulating material 11 . like Figure 11D As shown, the foam heat insulation protection material 10A on the lower side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com