Soil sample film loader for earth motion triaxial test

A dynamic triaxial test and soil sample technology, which is used in the preparation of test samples, instruments, measuring devices, etc. Test efficiency and other issues to achieve the effect of reducing labor costs, improving speed, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

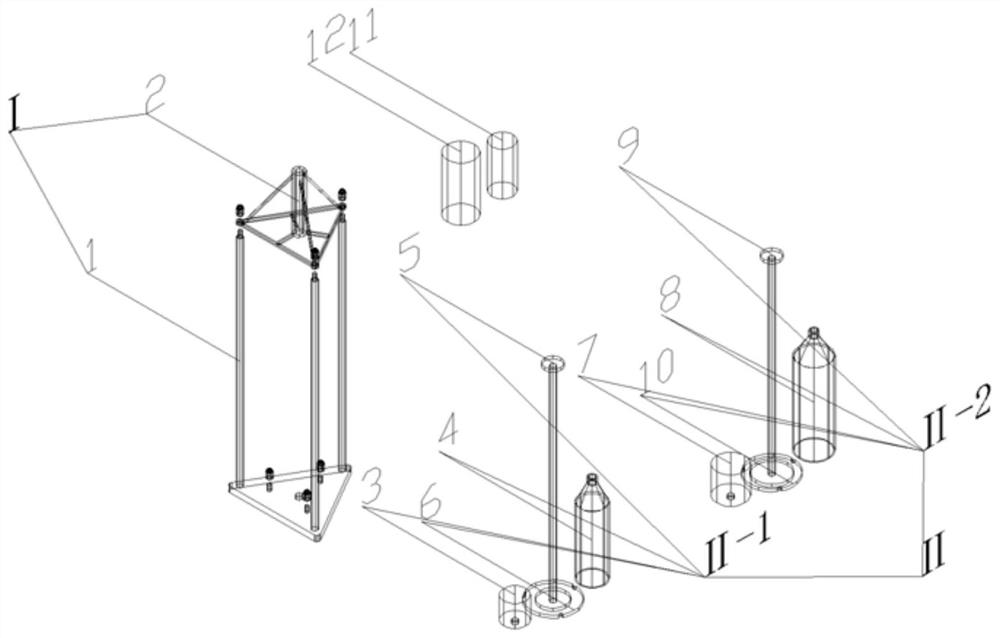

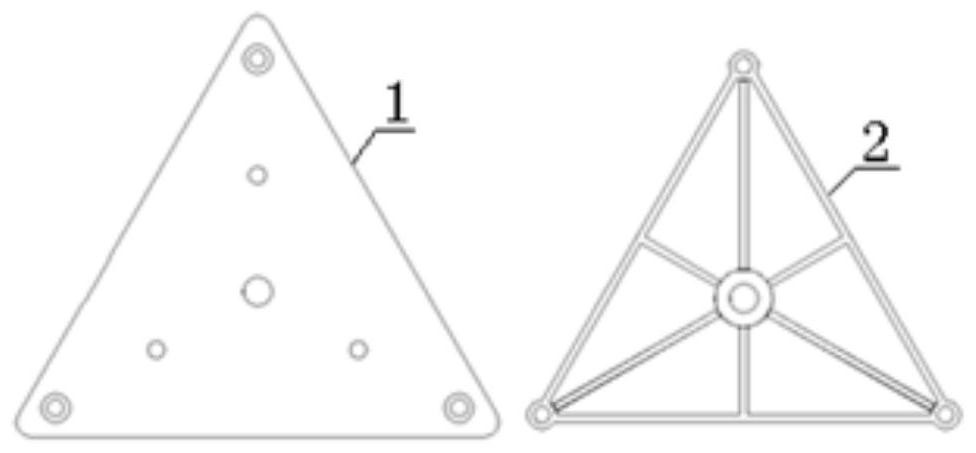

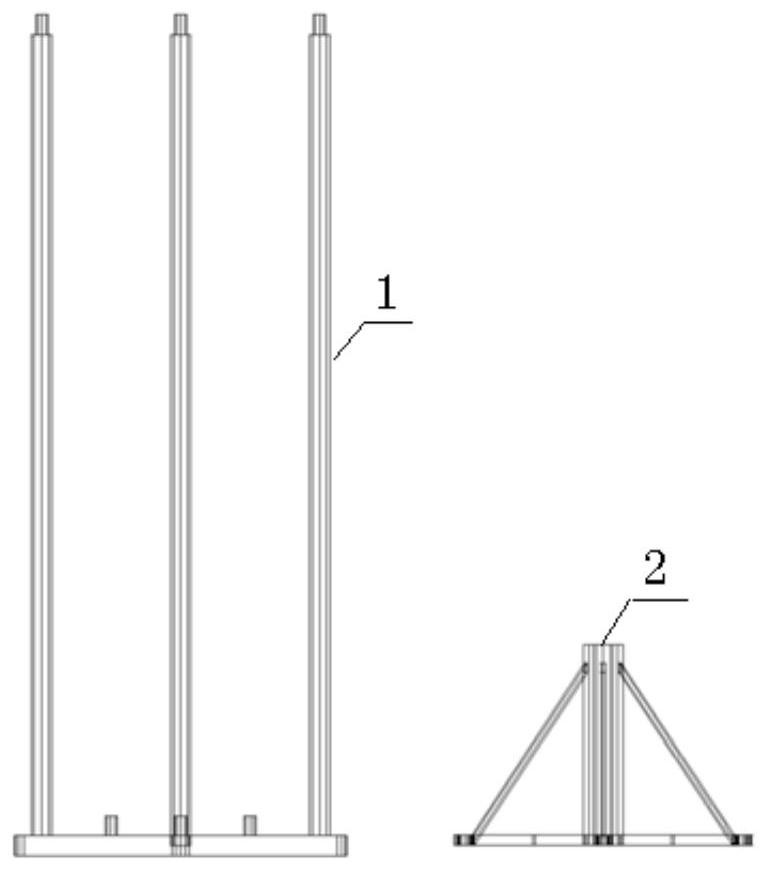

[0031] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-9As shown, a soil dynamic triaxial test soil sample membrane device includes a triangular fixing device (I) and a membrane loading device (II), and the triangular fixing device (I) includes a triangular base fixing device (1) and a triangular top frame fixing device (2), the film loading device (II) includes a set of film loading device (II-1) prepared for a soil sample with a diameter of 39.10 mm and a set of film loading device (II-1) prepared for a soil sample with a diameter of 50.00 mm -2), said set of film loading device (II-1) prepared for the soil sample with a diameter of 39.10mm comprises a soil sample stand (3), a soil sample sleeve (4), a soil sample sleeve lifting rod (5 ) and a rubber membrane pressure ring (6), the set of membrane loading device (II-2) prepared for a soil sample with a diameter of 50.00 mm includes a soil sample stand (7), a soil s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com