Pre-filling cartridge bottle

A technology for pre-filling cartridges and cartridges, which is applied in the field of medical devices, can solve problems such as cumbersome operation steps, inability to inject doses, and operational errors, and achieve the effects of convenient use, low production cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

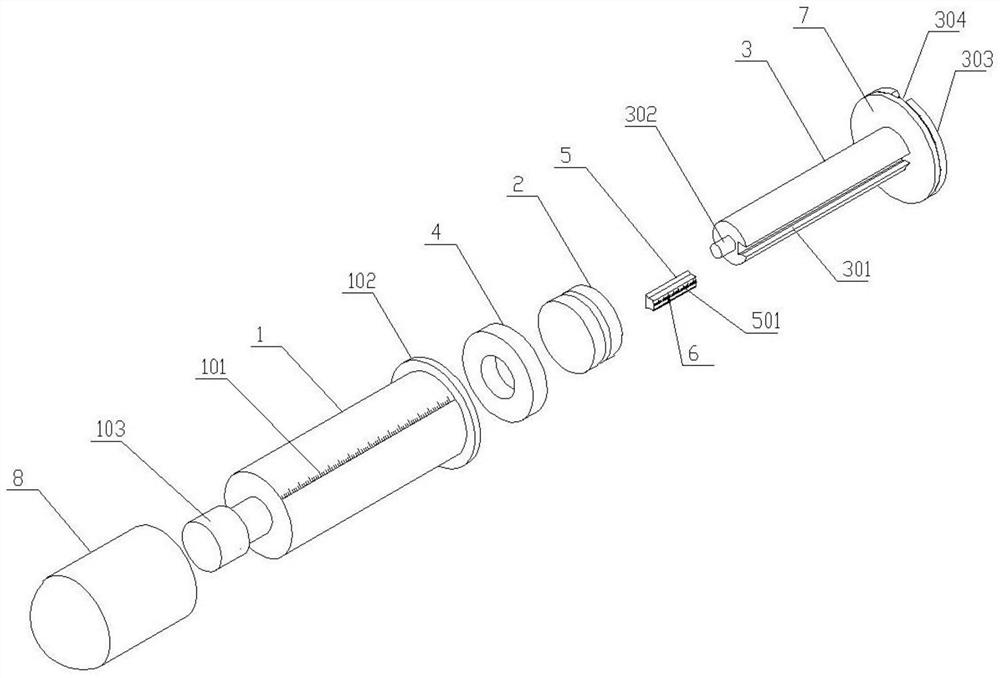

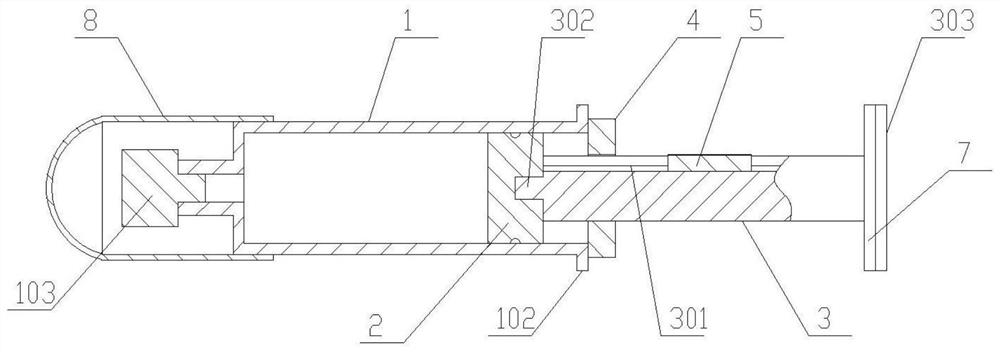

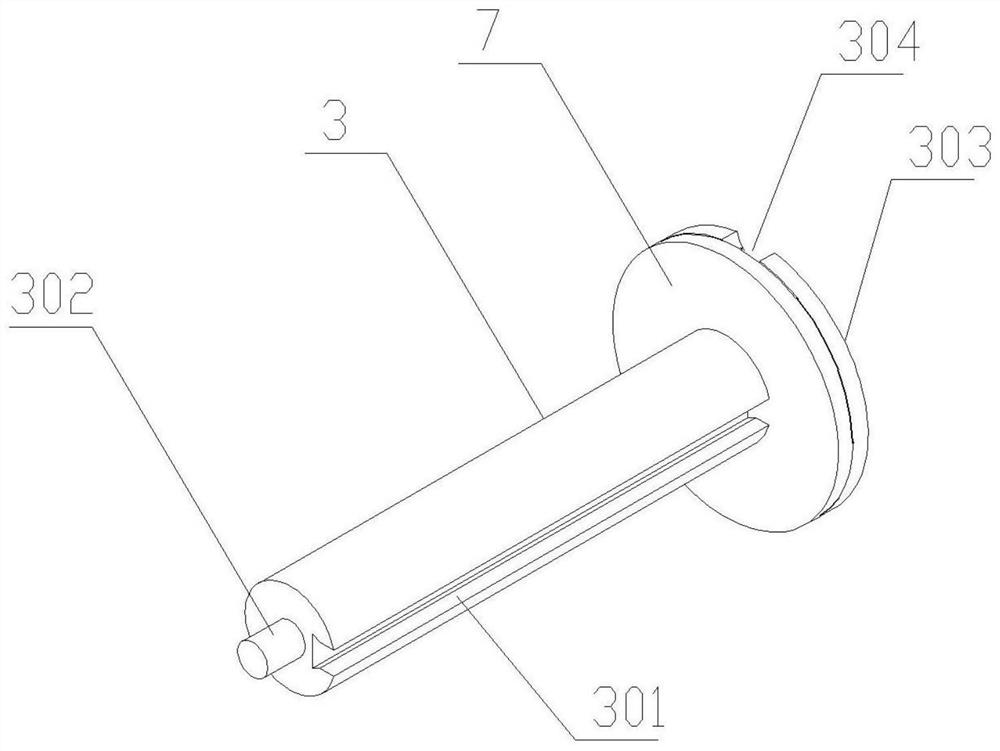

[0037] see Figure 1-5 shown;

[0038] Invented the pre-filled cartridge bottle, including: bottle body 1 and push rod 3

[0039] The head end of the bottle body 1 is equipped with an aluminum cover 103, and of course a plastic cover can also be used. The aluminum cover 103 is provided with a rubber plug for sealing the head end of the bottle body 1. The tail end of the bottle body 1 has a piston 2, and the piston 2 is in the Driven by the push rod 3, it can be displaced along the inner wall of the bottle body 1. The push rod 3 is sheathed with a dosage plug 4. In addition, the bottle body 1 is made of a transparent material that allows the liquid medicine to be seen. The material can be transparent glass or medical plastic in the prior art, or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com