Multi-connected variable foam generator

A foam generator and variable technology, which can be used in fire rescue and other fields, and can solve the problems affecting the foam expansion ratio and range, the foam expansion form and the expansion ratio are single, unstable, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

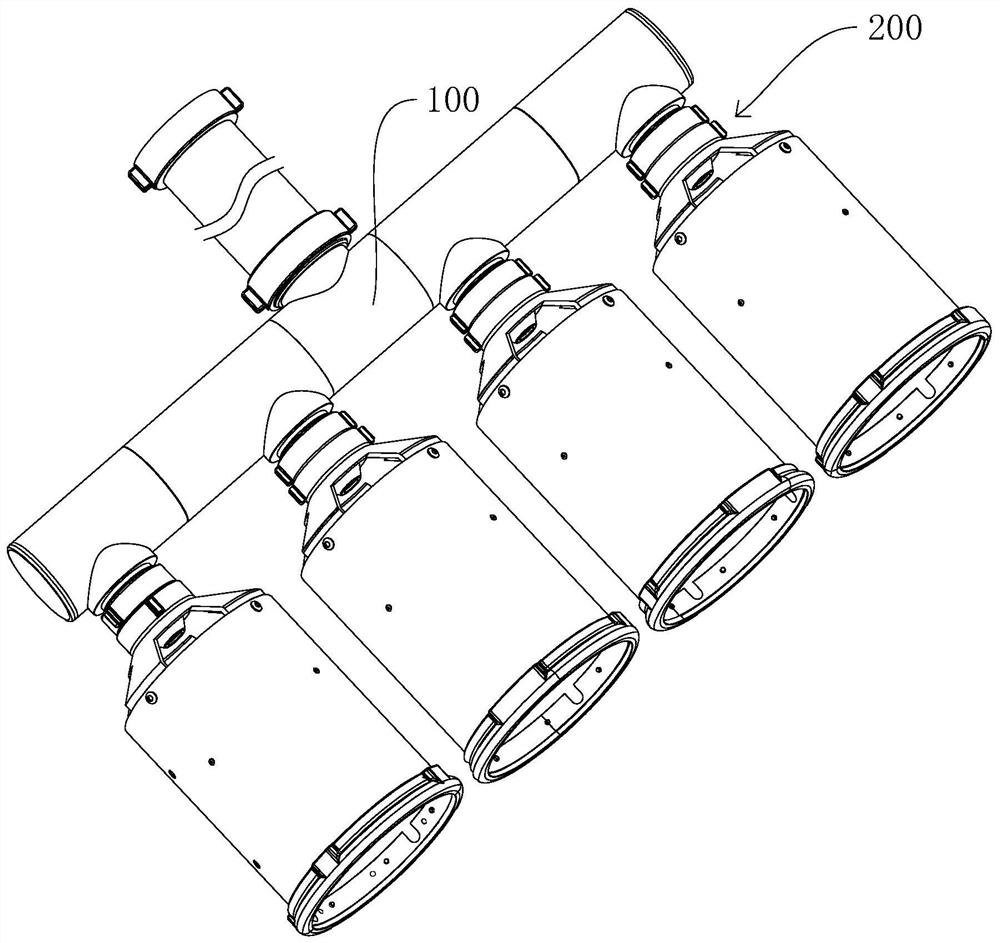

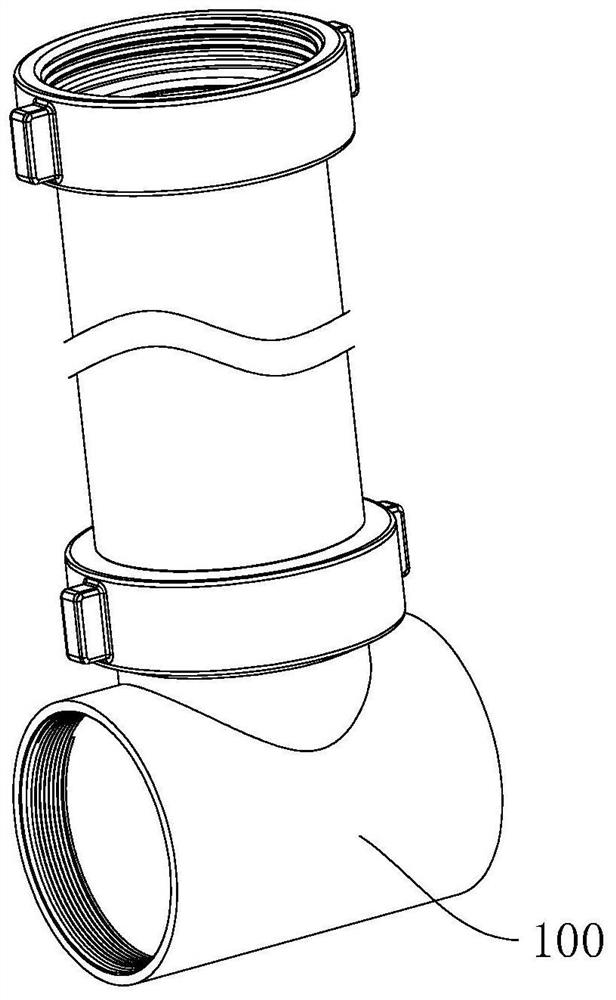

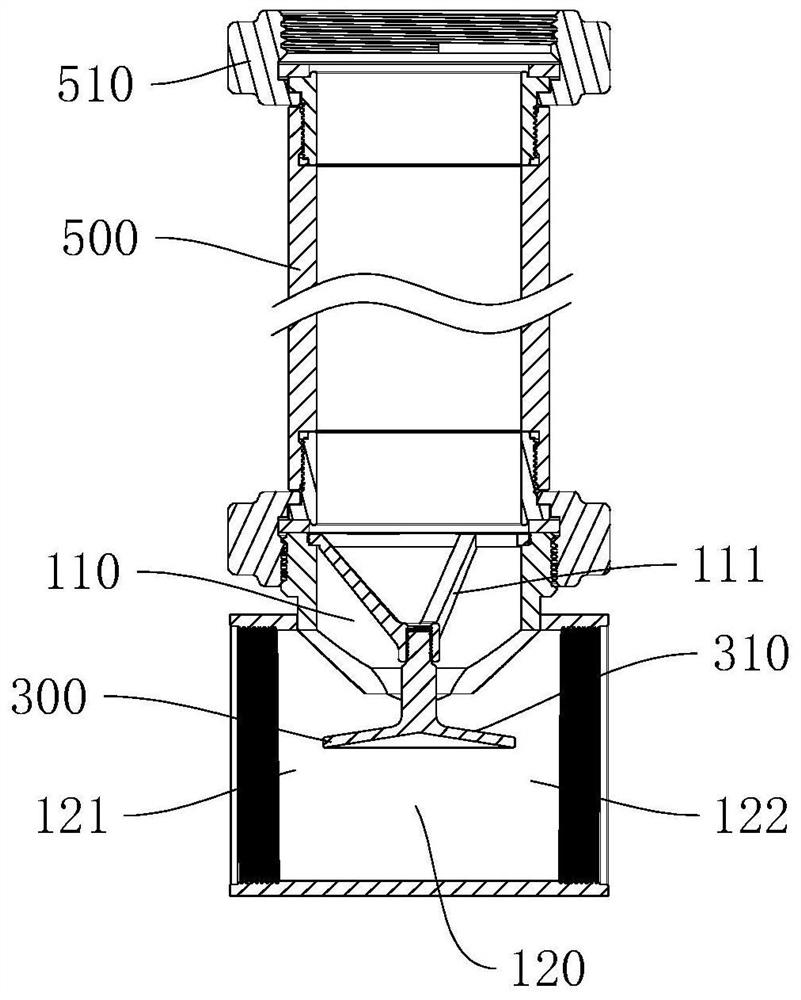

[0052] A multi-connected variable foam generator, such as Figure 1 to Figure 9As shown, the foam generator includes a body 100 and a nozzle 200. The body 100 has an inlet channel 110 and an outlet channel 120 connected thereto. There are at least two nozzles 200. Several nozzles 200 are detachable from the body 100. connected, and the nozzles 200 are all in communication with the outlet channel 120.

[0053] Preferably, the outlet channel 120 has an outlet one 121 and an outlet two 122 , and several nozzles 200 are detachably connected to the outlet one 121 and / or the outlet two 122 .

[0054] The several gun heads 200 are detachably connected, and the several gun heads 200 communicate with each other.

[0055] A diverter plate 300 is disposed inside the body 100 , and the diverter plate 300 can divide the medium in the outlet channel 120 into the gun head 200 . Further, a fixing frame 111 is arranged in the inlet channel 110 , and the diverter plate 300 is connected to the...

Embodiment 2

[0070] The difference between embodiment two and embodiment one is: as Figure 10 to Figure 12 As shown, at least one foaming device 400 is disposed on the body 100 and communicates with the outlet channel 120 , and the other nozzles 200 are detachably connected to the first outlet 121 and / or the second outlet 122 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com