Transfer robot and substrate processing apparatus having the same

A technology of substrate processing system and robot, which is applied in the direction of conveyor objects, manipulators, transportation and packaging, etc., which can solve the problems of reduced output and reduced quality of substrate processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

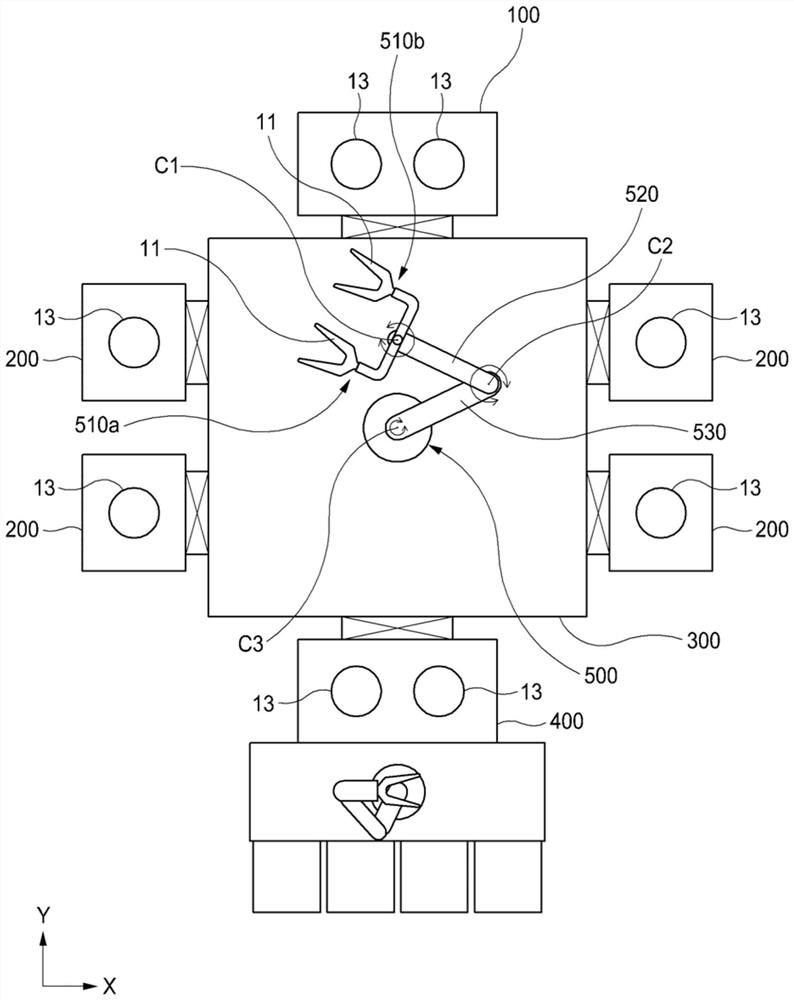

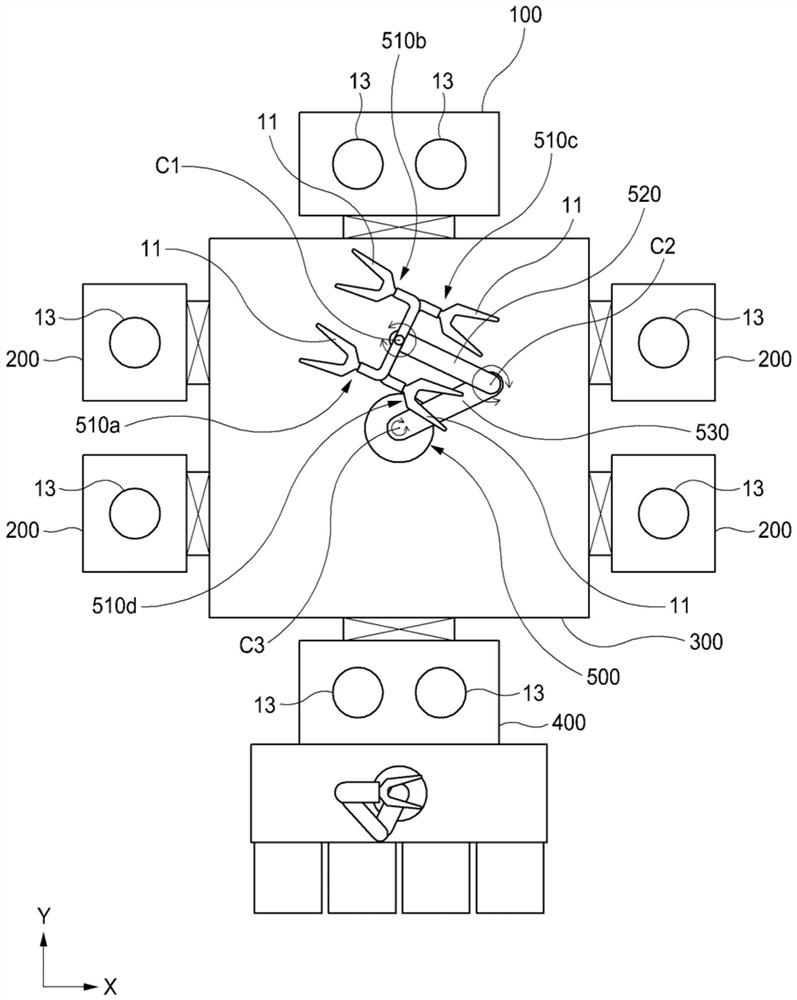

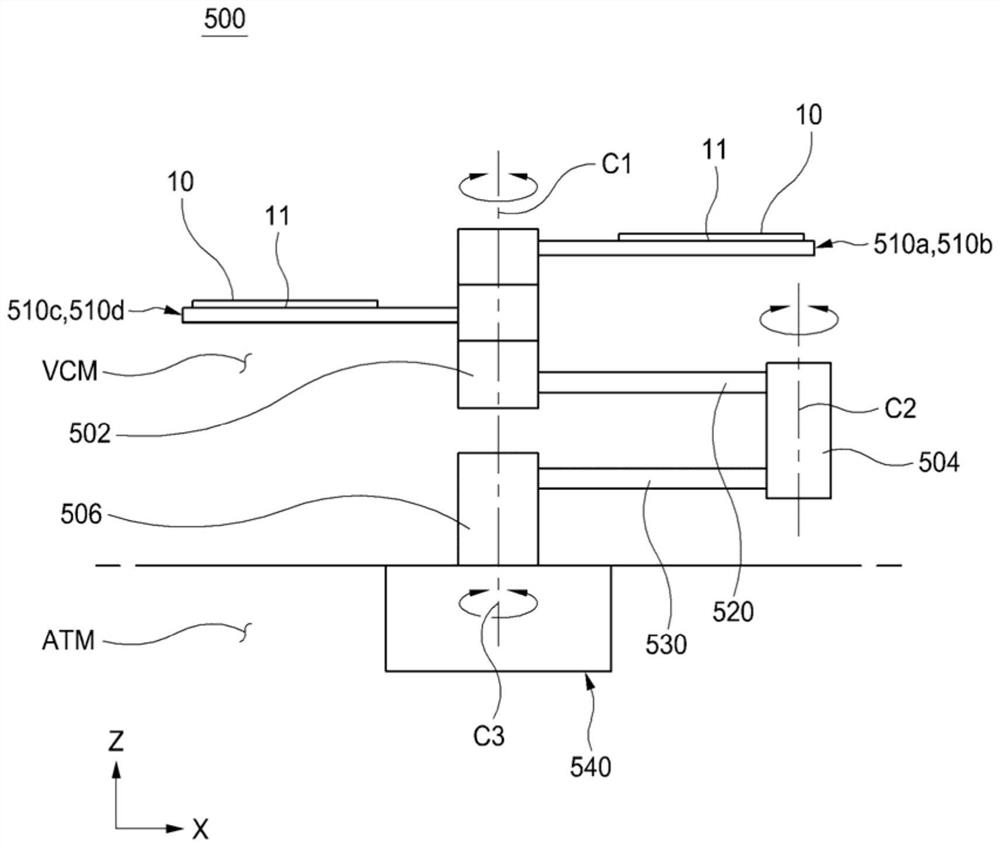

[0041] Hereinafter, the following description with reference to the accompanying drawings substrate processing system according to the present invention.

[0042] The substrate processing system of the present invention as a system for performing deposition, etching, etc. of the substrate processing substrate 10, such as Figures 1A to 5B Shown, comprising: a transfer module 300 having a transfer robot 500 for transporting a substrate; at least one pair of process module 100, disposed at one side of the transfer module 300, while two out of the substrate 10, and arranged in a horizontal direction a pair of substrates disposed two supporting portions 10, 13; more than a single process module 200, disposed at one side of the transfer module 300, out of a substrate 10, and a substrate having a substrate 10 for placing the supporting portion 13.

[0043] Here, the substrate 10 may be a semiconductor wafer, glass substrate for the LCD panel, the OLED with a variety of substrates, solar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com