Lamp power line fixing structure and implementation method thereof

A technology for fixing structures and power cords, applied in circuit layout, lighting devices, components of lighting devices, etc., can solve the problem that the wiring harness is easy to rotate and fall off, increase product thickness, operating procedures and material costs, and affect production efficiency and product safety. and other problems to achieve the effect of reducing cost increase and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

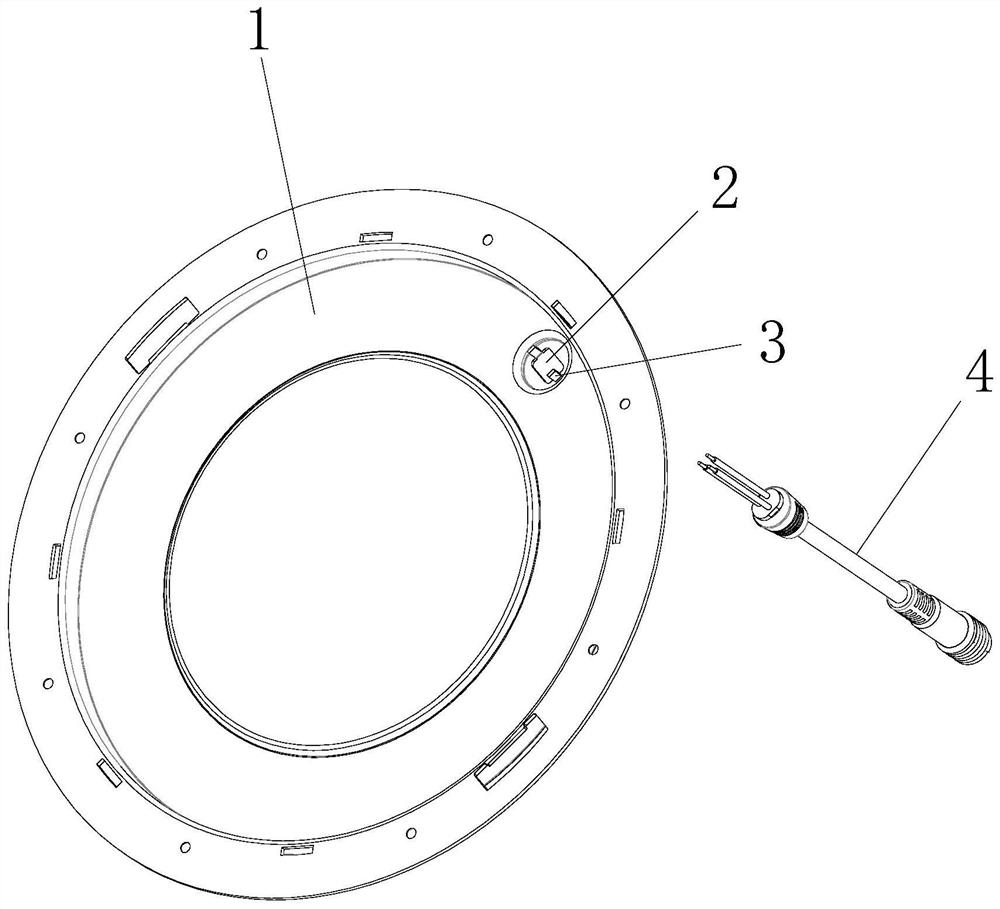

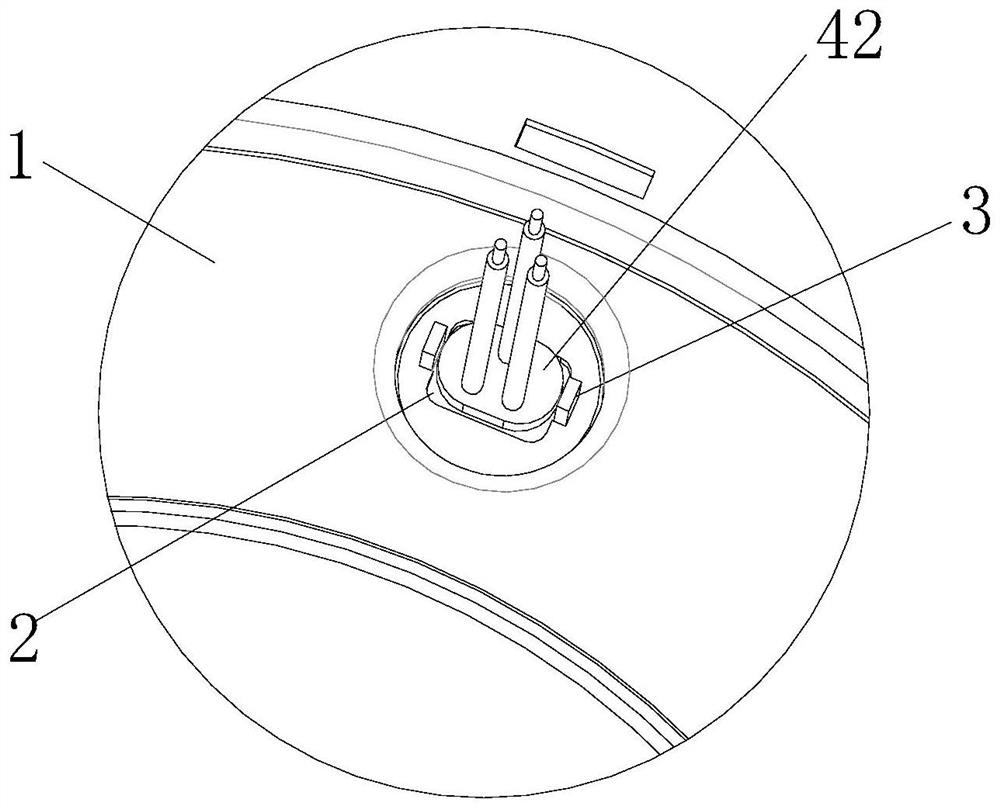

[0031] see Figure 1-5 , the present invention provides the following technical solutions: a lamp power cord fixing structure, including a metal shell 1 and a power cord body 4, the metal shell 1 is provided with a threading hole 2, the two sides of the threading hole 2 are provided with bending blocks 3, the power supply The circumference of the end of the wire body 4 is provided with a tail clip 42, and the tail clip 42 passes through the threading hole 2 and is fixed to the metal shell 1 by bending the bending block 3.

[0032] Specifically, the threading hole 2 is a rectangular structure, the bending blocks 3 are arranged on both sides of the short sides of the threading hole 2 , and the tail clip 42 is a rectangular structure with the same size as the threading hole 2 .

[0033] By adopting the above technical solution, after the tail clip 42 passes through the threading hole 2 and rotates 90 degrees, the threading hole 2 can limit the position of the tail clip 42 to prev...

Embodiment 2

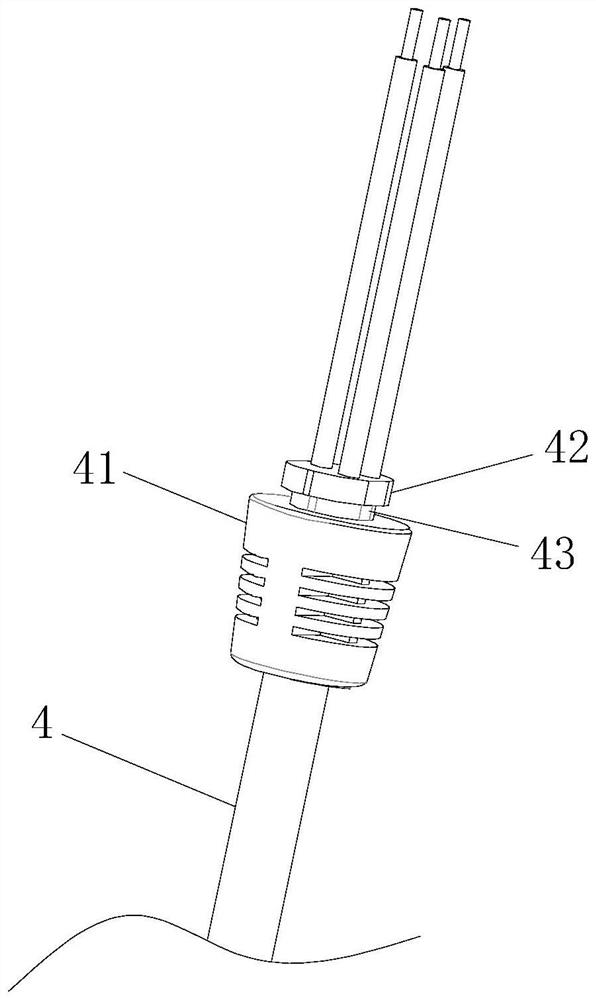

[0039] The difference between this embodiment and Embodiment 1 is that specifically, the circumference of the end of the power cord body 4 is also provided with a boss 41 located below the end card 42 and connected to the end card 42, and the boss 41 is a circular truncated structure , The diameter of the top surface of the boss 41 is larger than the length of the long side of the threading hole 2 .

[0040] By adopting the above technical solution, the power cord body 4 is limited by the boss 41 to prevent the power cord body 4 from being pushed in during installation or transportation. In addition, the boss 41 can restrain the wire hole 2 to a certain extent. Sealed so that it has a certain level of waterproofing.

[0041] Specifically, a rotating groove 43 is provided between the boss 41 and the tail clip 42 , and the width of the rotating groove 43 is greater than or equal to the thickness of the metal casing 1 .

[0042] By adopting the above technical solution, the tail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com