Automatic control method of air suction equipment and air suction equipment

A kind of equipment and high-level technology, applied in the field of household appliances, can solve the problems of mis-shutdown, range hood installation height change, infrared temperature sensor temperature change curve inconsistency, etc., and achieve the effect of precise control of opening and closing or power adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

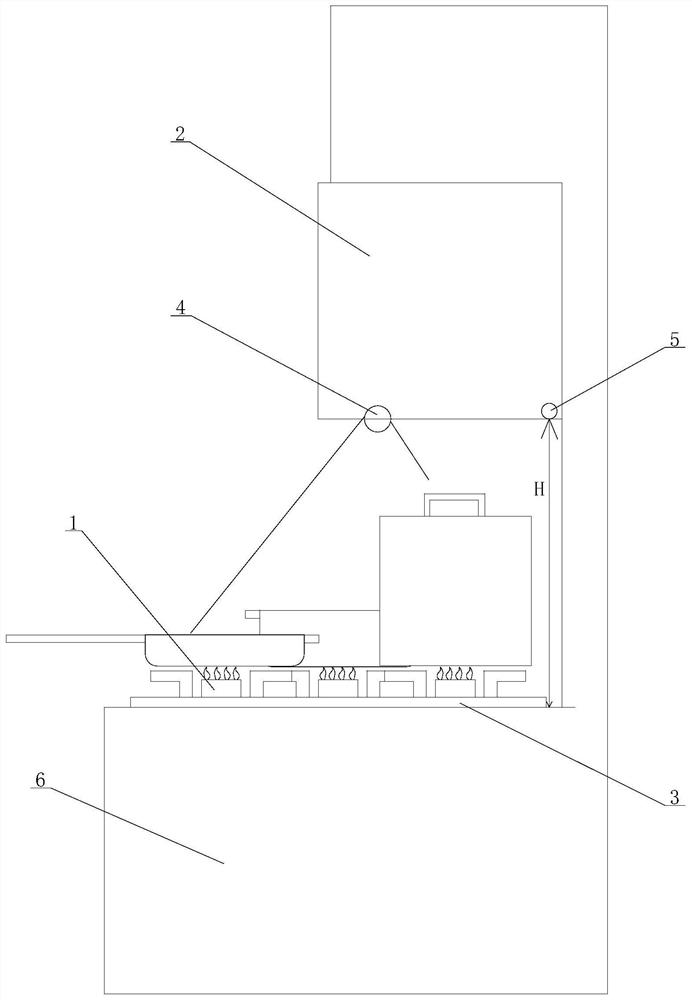

[0025] see Figure 1-Figure 2 , the automatic control method of the suction device, comprising the following steps:

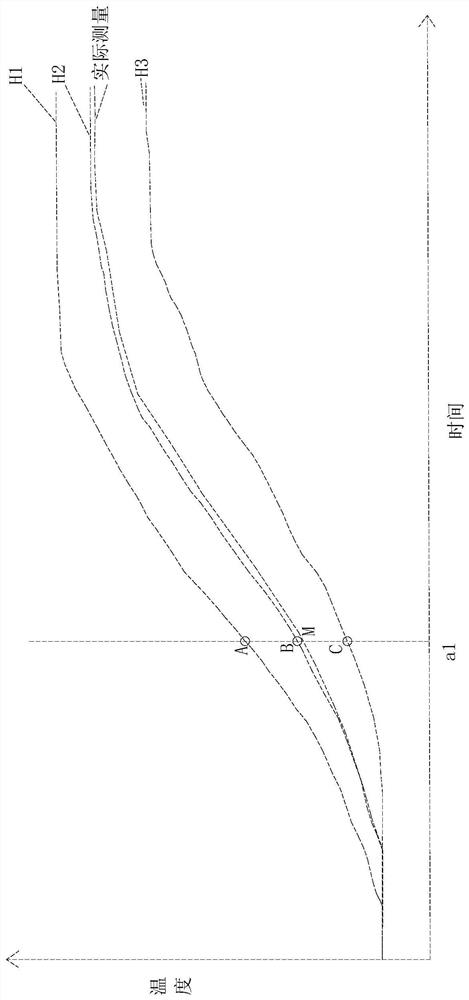

[0026] A. According to the actual application of the air suction device 2, the air suction device 2 is pre-installed at three different height positions above the cooker 1, which are: height level position H1, height level position H2, and height level position H3. The temperature values of the cooker 1 are measured at different height levels, and then the start-up threshold value of each height level position is analyzed, and the start-up threshold value is the value associated with the temperature for starting the suction device 2;

[0027] B. When cooking range 1 is actually cooking, measure the actual distance between the suction device 2 and the range 1 through the distance measuring device on the suction device 2 to obtain the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com