An injection mold opening and closing control mechanism in shoe molding equipment

A molding equipment and injection mold technology, applied in the field of machinery, can solve the problems of complex hydraulic system structure, inconvenient processing, affecting control accuracy, etc., and achieve the effect of strengthening mold clamping effect, improving stability and quality, and reducing manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

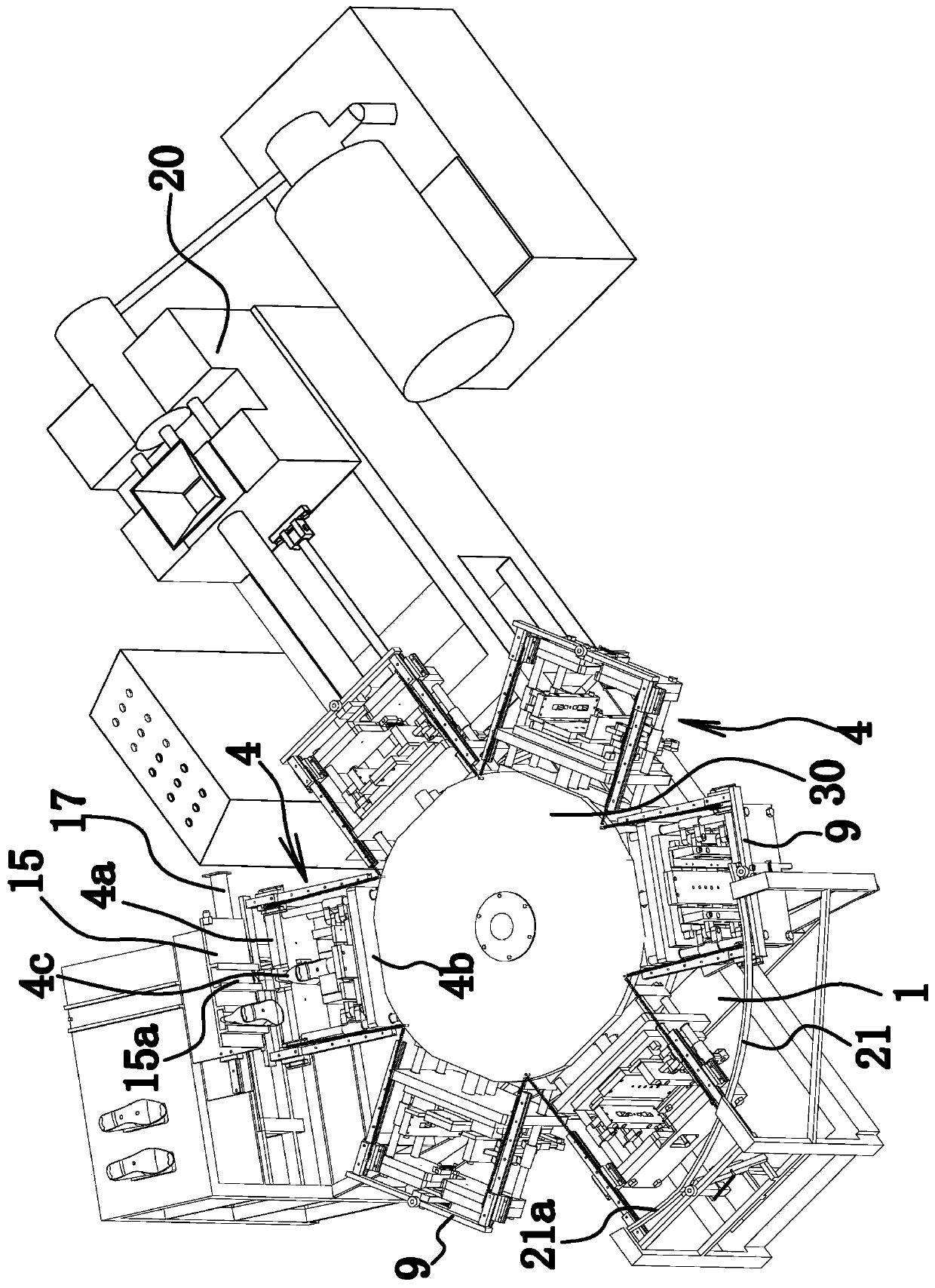

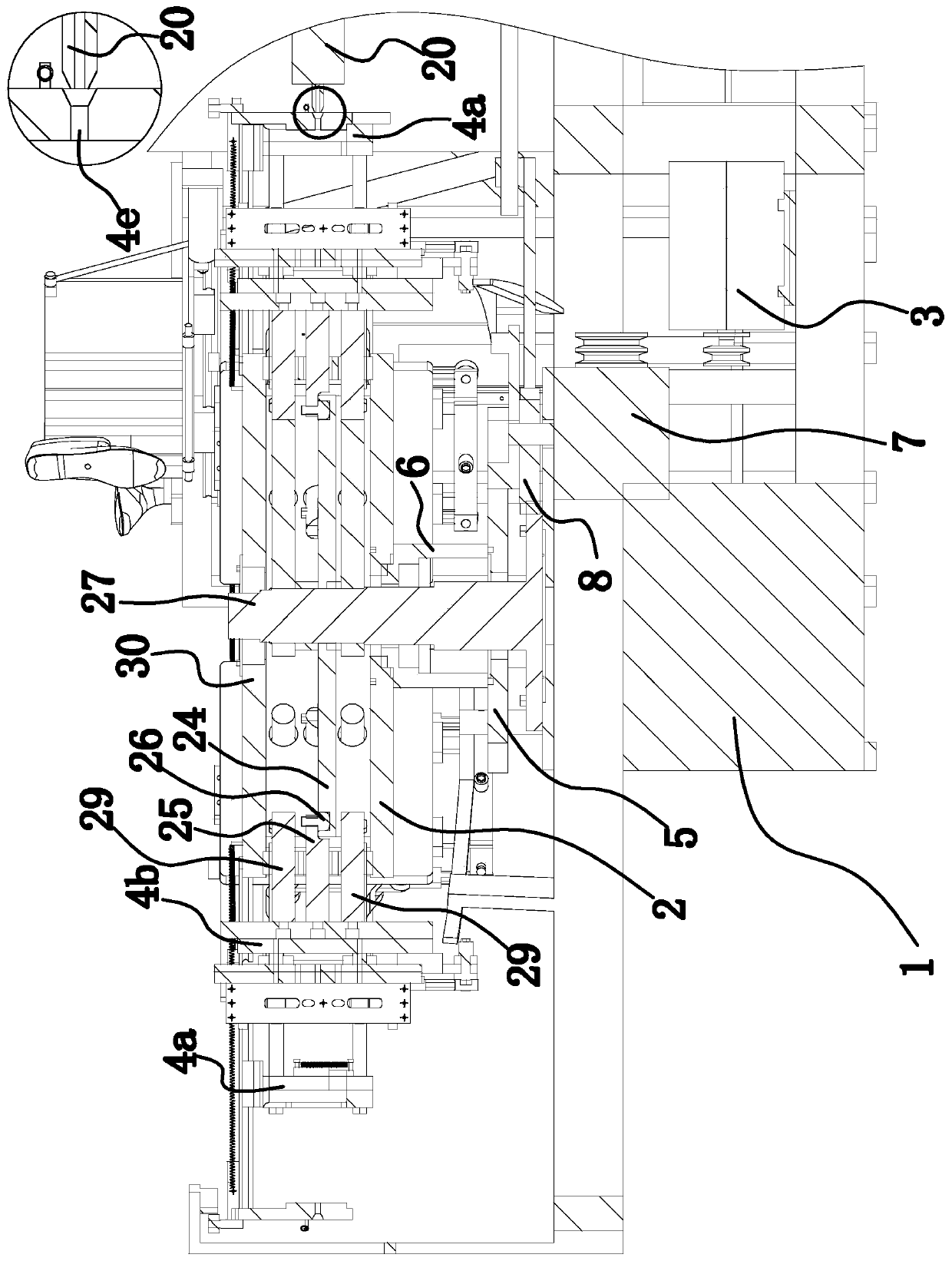

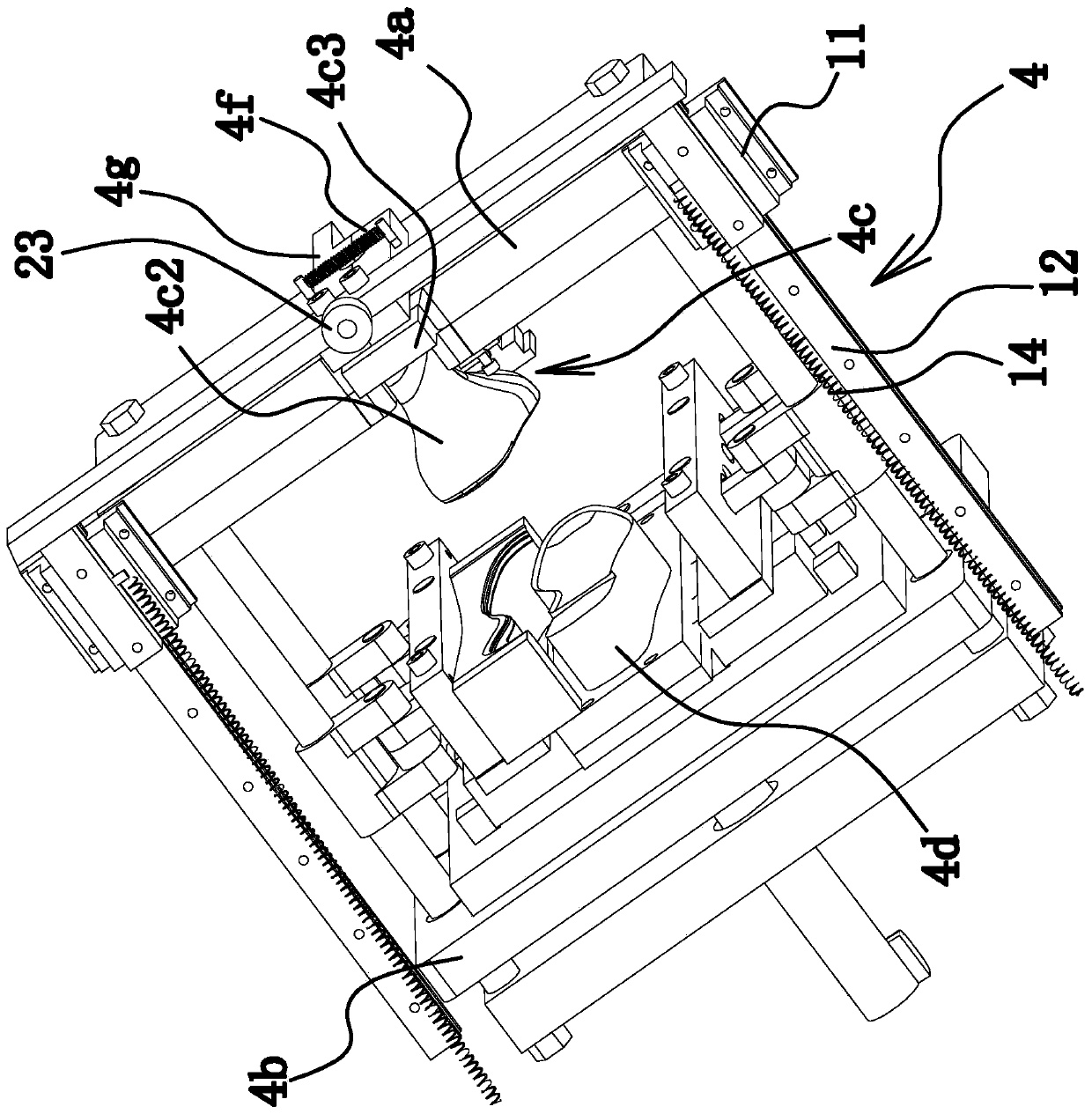

[0028] like figure 1 As shown, the shoe forming equipment is composed of a frame 1, a turntable 2, a motor 3, an injection mold 4, a shoe last changing mechanism, an injection molding mechanism 20, a material removing head mechanism, a control mechanism and the like.

[0029] Wherein, the turntable 2 is disc-shaped and arranged on the frame 1 along the horizontal direction, and the turntable 2 is rotatably connected with the frame 1 through a rotating shaft 6 . The motor 3 is installed on the frame 1 and can drive the turntable 2 to rotate around the axis. Specifically, as figure 2 As shown, the pinion gear 5 is fixed on the rotating shaft 6, the gearbox 7 is fixed on the frame 1, the main shaft of the motor 3 is connected with the input shaft of the gearbox 7 through a synchronous belt transmission structure or a gear transmission structure, and the output shaft of the gearbox 7 The main gear 8 is fixed on the top, and the main gear 8 and the auxiliary gear 5 are meshed, s...

Embodiment 2

[0052] The structure and principle of the second embodiment are basically the same as those of the first embodiment, except that the driving member 21 is the first cylinder fixed on the frame 1, and the piston rod of the first cylinder is opposite to the guide block 9.

Embodiment 3

[0054] The structure and principle of the present embodiment three are basically the same as those of the first embodiment, except that the separating part 22 is the cylinder two fixed on the frame 1, and the piston rod of the cylinder two can offset the rubber block two 4g to drive the rubber block. Block two 4g overcome the elastic force rotation of spring one 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com