A glue machine for mask production

A technology for gluing machines and masks, applied in applications, tools for sewing clothes, devices for coating liquid on surfaces, etc., can solve problems such as inaccurate dispensing positions, unfavorable connections between ear loops and masks, and achieve improved The quality, reduce the chance of random flow, ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

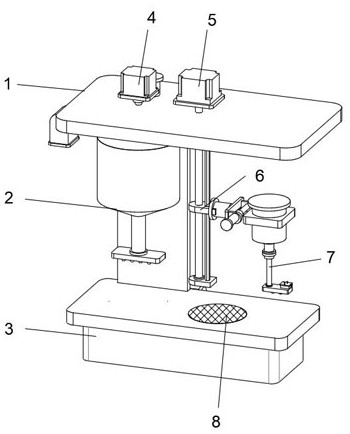

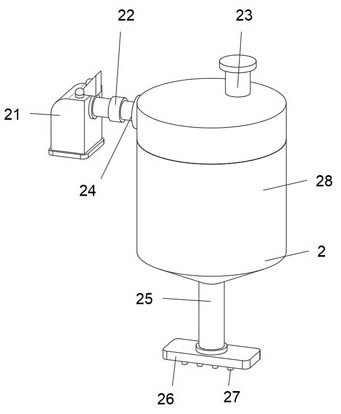

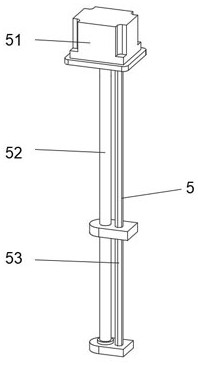

[0031] Please refer to Figure 1 to Figure 9 A gluing machine for mask production comprises: a base 3, the upper surface of the base 3 is fixedly connected with a top plate 1 through a bracket 9; a glue outlet mechanism 2, and the glue outlet mechanism 2 is connected with the top plate 1; A mechanical arm for adjusting the position of the glue outlet of the glue outlet mechanism 2 is installed on the support 9; a mounting plate 6 is located between the base 3 and the top plate 1; The driving mechanism 5 that moves in the vertical direction; The mask indentation mechanism 7 with rotation function, the mask indentation mechanism 7 with rotation function is connected with the mounting plate 6; The mask restraint mechanism 8, the mask restraint mechanism 8 is connected with the base 3 Connected, and the mask constraining mechanism 8 is located below the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com