Axial position adjusting mechanism for eccentric bearing of full-oilless vortex air compressor

A technology of adjusting mechanism and eccentric bearing, applied in machine/engine, rotary piston machinery, mechanical equipment, etc., can solve the problems of difficulty in ensuring the safety of workers, inconvenient installation of eccentric bearings, etc., to improve the lubrication effect and facilitate the movement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

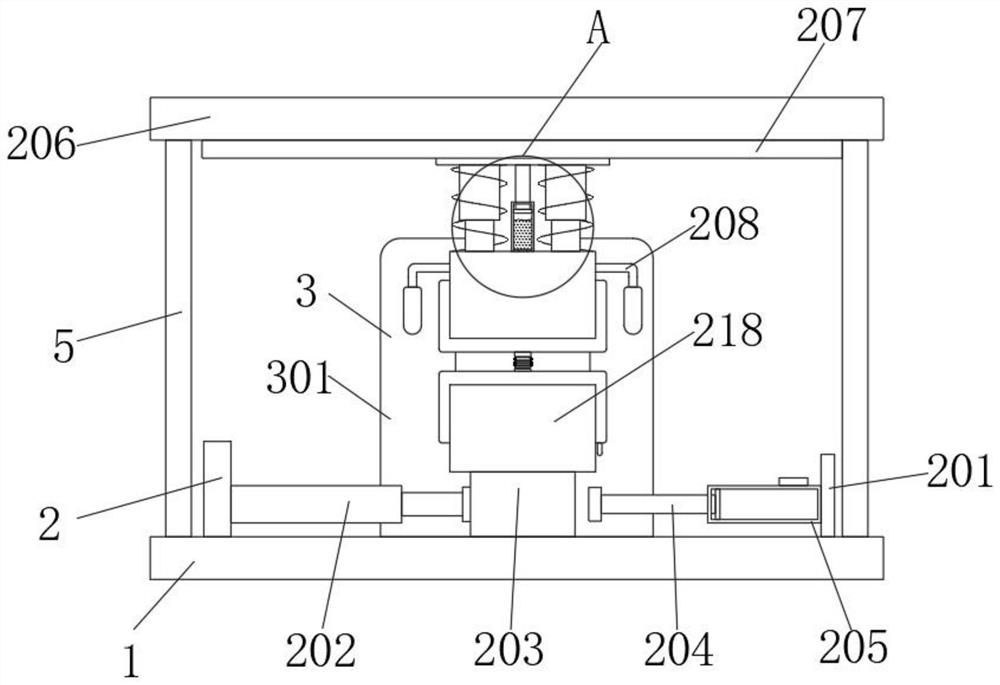

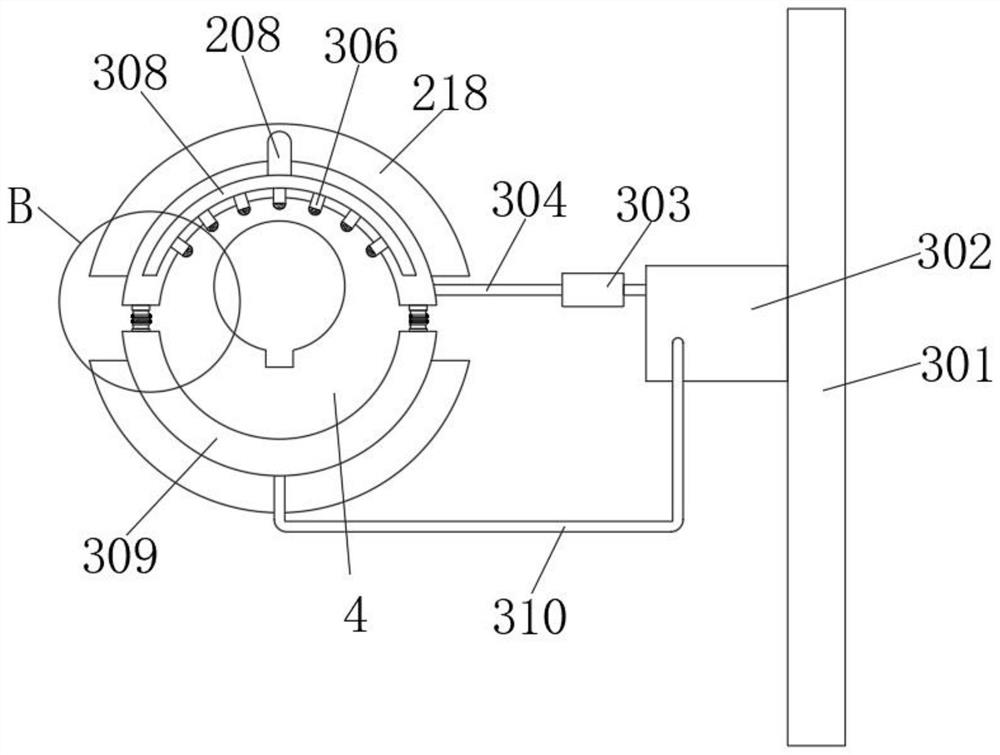

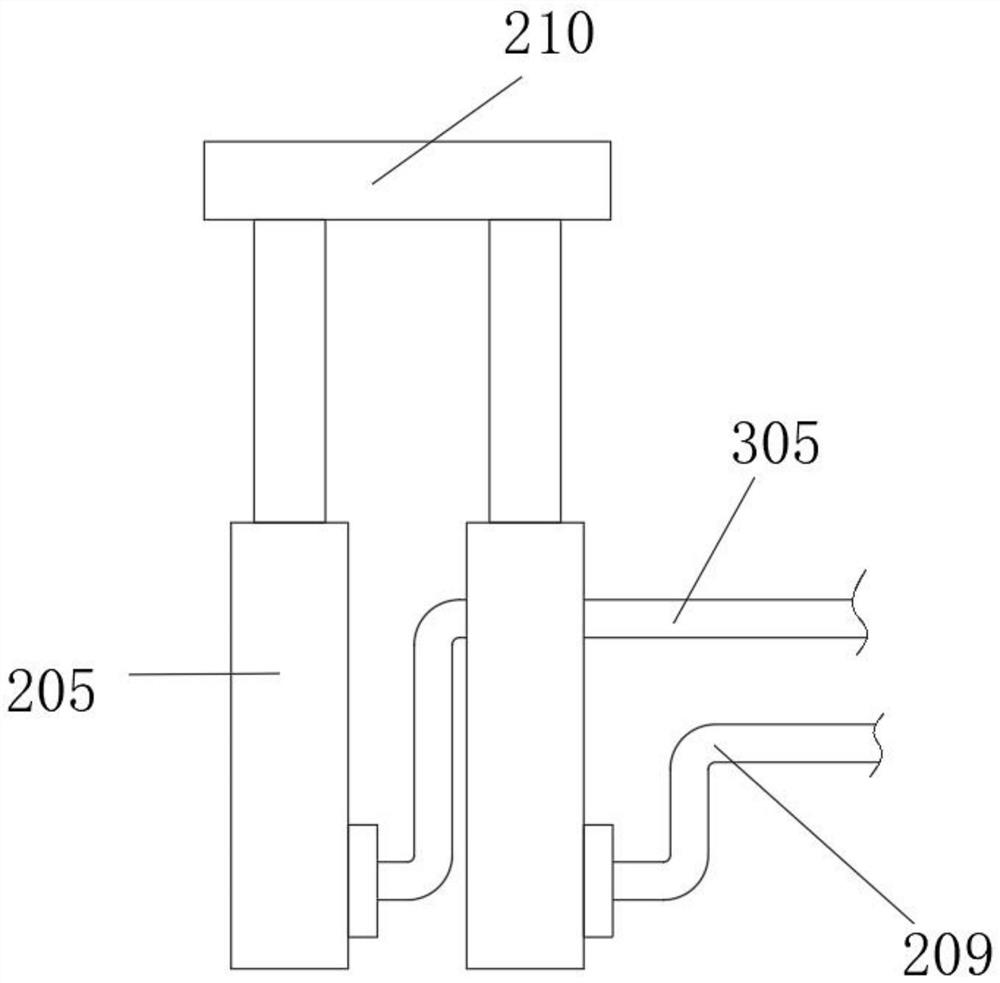

[0029] Example 1, such as Figure 1-5As shown, the present invention provides an oil-free scroll air compressor eccentric bearing axial position adjustment mechanism, including a base 1, the top of the base 1 is provided with an adjustment mechanism 2, and the top of the adjustment mechanism 2 is provided with a lubricating mechanism 3, The adjustment mechanism 2 includes two fixed vertical plates 201, wherein an electric telescopic rod 202 is fixedly installed on the right side of the fixed vertical plate 201, and a support block 203 is fixedly installed on the right side of the electric telescopic rod 202, and a left The side is fixedly installed with two first hollow blocks 205, and the bottom of one of the first hollow blocks 205 is fixedly installed with a second connection pipe 209, and the other end of the second connection pipe 209 is fixedly installed with a connection hollow block 213, and the connection hollow block 213 The two sides of the bottom are fixedly instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com