Evaluation method for radial circle run-out error of optical axis

A circular runout and error technology, applied in the fields of precision measurement and computer applications, can solve the problems of initial value sensitivity, inability to take into account stability, speed and simple form at the same time, and achieve the effect of simple form, industrial possibility and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

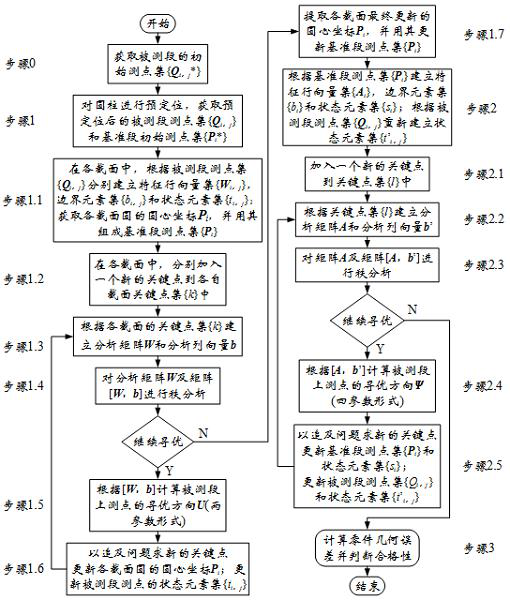

Method used

Image

Examples

Embodiment Construction

[0089] The following are specific embodiments of the present invention, and the solutions of the present invention will be further described with reference to the accompanying drawings, but the present invention is not limited to these embodiments.

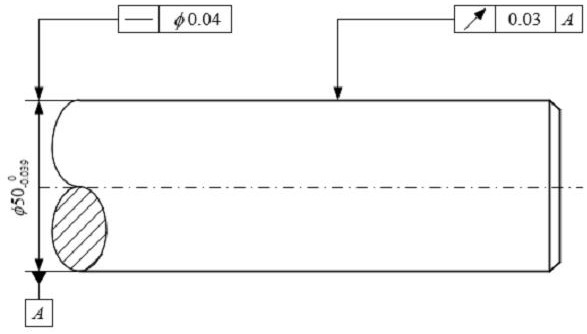

[0090] To evaluate the radial circular runout error of a shaft, the tolerance design specifications are as follows figure 2 shown.

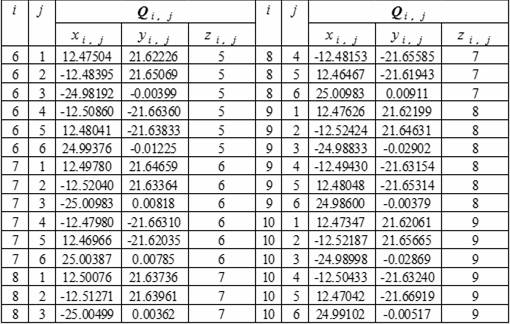

[0091] Step 0: Get the initial measuring point set of the measured segment { Q i,j *}as follows:

[0092]

[0093]

[0094] After step 0, proceed to step 1.

[0095] Step 1: Obtain the measured point set of the measured section after pre-positioning{ Q i,j}as follows:

[0096]

[0097]

[0098]

[0099] Get the initial measurement point set of the pre-positioned reference segment { P i *}as follows:

[0100]

[0101] After step 1, proceed to step 1.1.

[0102] Step 1.1: Taking section 1 as an example, according to the measuring point set of the measured section corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com