Method for transferring a useful layer onto a support substrate

A transfer method and carrier substrate technology, applied in the field of microelectronics, can solve the problems of inhomogeneity of the useful layer 3, difficulty in eliminating inhomogeneity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

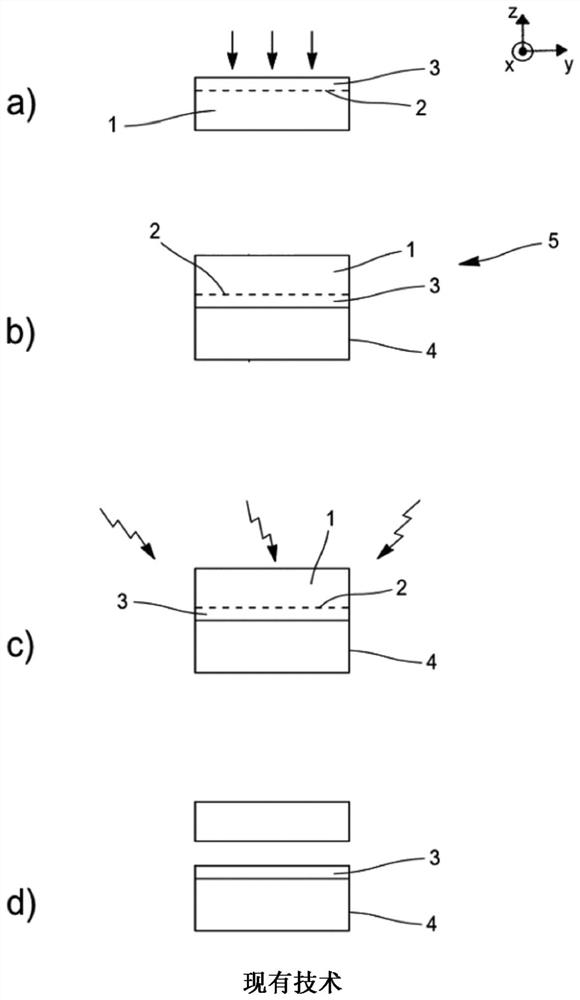

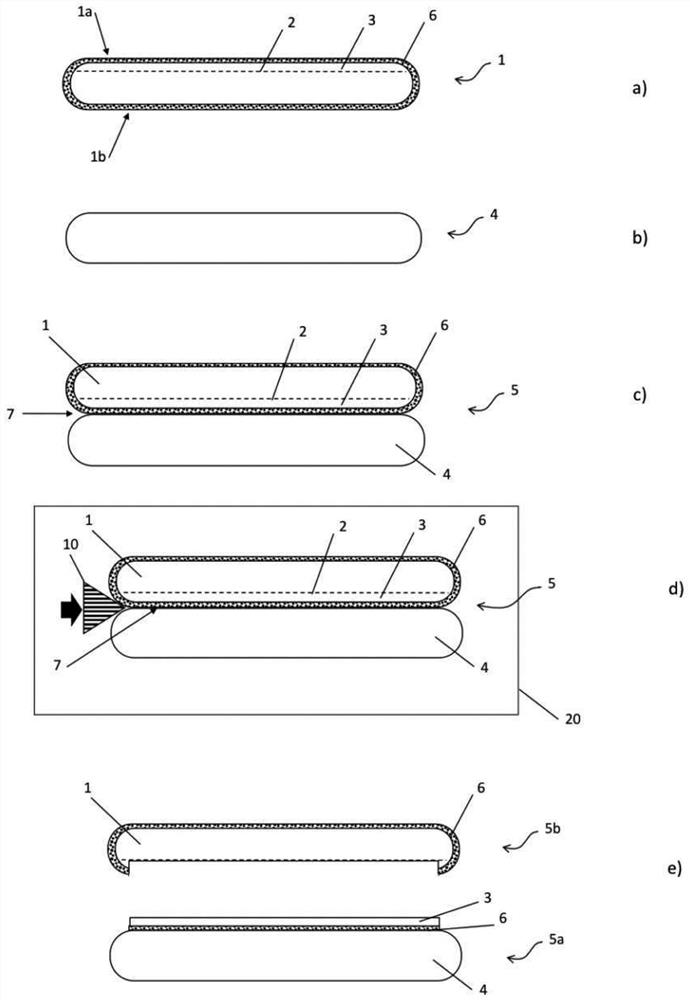

[0043] In the description, the same reference numerals may be used for the same type of elements in the drawings. The figures are schematic representations, not drawn to scale for the sake of clarity. In particular, the thicknesses of the layers along the z-axis are not proportional to the lateral dimensions along the x- and y-axes; the relative thicknesses of these layers relative to each other are not necessarily relative in the drawings. It should be noted that figure 1 The coordinate system (x,y,z) for figure 2 .

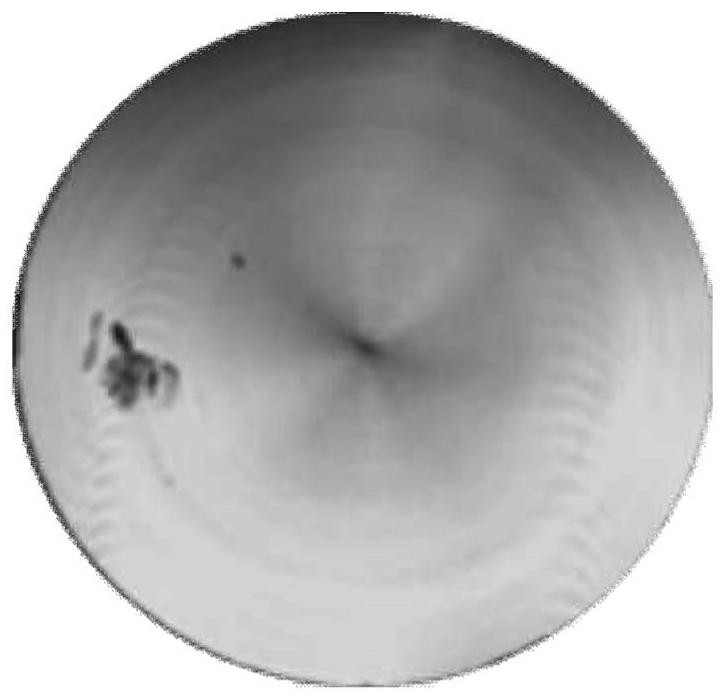

[0044] The invention relates to a method for transferring a useful layer 3 onto a carrier substrate 4 . The useful layer 3 is so named because it is intended for the production of components in the field of microelectronics or microsystems. The properties of the useful layer and the carrier substrate may vary depending on the target component type and target application. Since silicon is currently the most commonly used semiconductor material, the useful l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com