Loop transfer device and method for high-density fabric

A high-density, transfer technology, used in knitting, weft knitting, textiles and papermaking, etc., can solve problems such as fabric defects, collision with transfer springs, and failure of transfer action, and achieve the effect of increasing the probability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

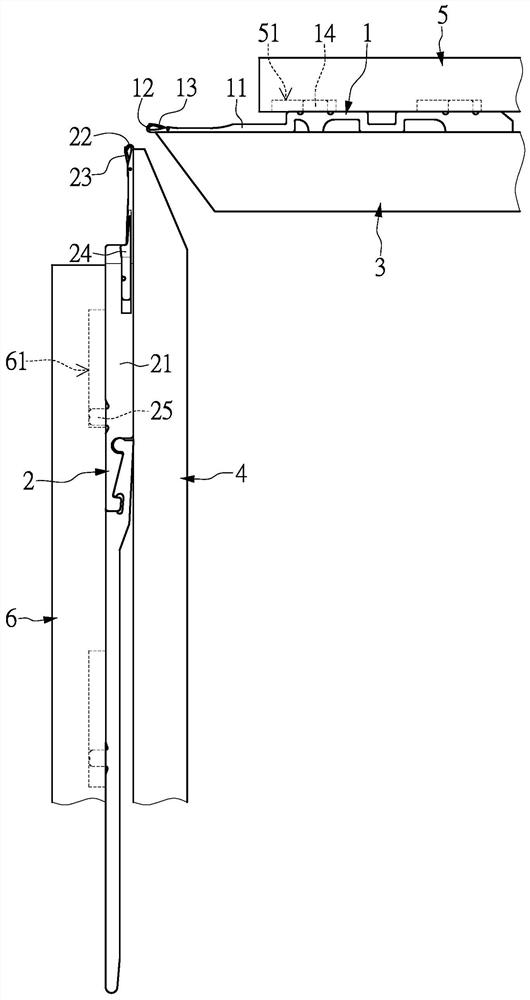

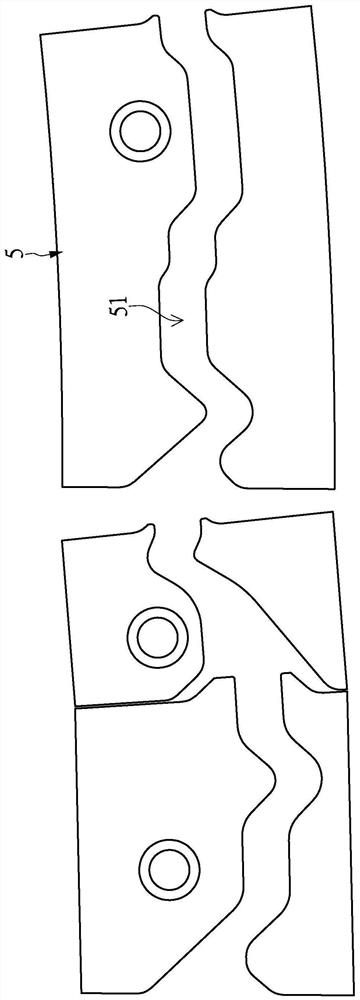

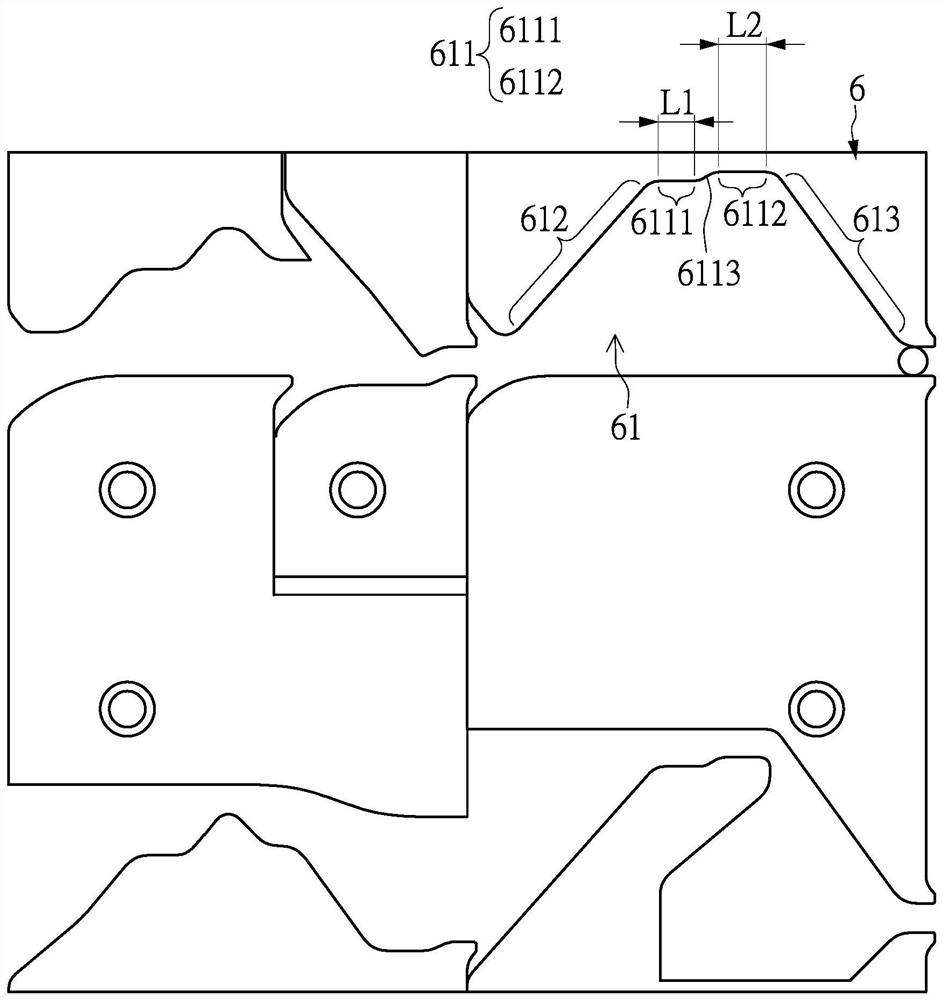

[0027] see Figure 1 to Figure 3 , the present invention provides a high-density fabric transfer device, the transfer device is applied to high-density fabrics, the transfer device includes a regular needle 1, a transfer needle 2, a machine dial 3 and a needle cylinder 4, usually circular The mechanism of the main knitting part of the loom includes a plurality of regular needles 1 and a plurality of transfer needles 2, and only one regular needle 1 and a transfer needle 2 are disclosed in the figure. The machine dial 3 and the needle cylinder 4 are vertically arranged. The regular needle 1 is arranged on the machine dial 3, that is, the machine dial 3 is provided with a plurality of dial needle grooves (figure omitted), and the regular needle 1 is arranged in the corresponding dial needle groove, and Can move horizontally. The transfer needle 2 is arranged on the needle cylinder 4, that is to say, the needle cylinder 4 is provided with a plurality of needle cylinder needle g...

no. 2 example

[0036] The present invention also provides a high-density fabric transfer method, comprising the following steps;

[0037] First of all, provide a transfer device (such as Figure 1 to Figure 3 As shown), the loop transfer device includes a regular needle 1, a loop transfer needle 2, a machine dial 3, a needle cylinder 4, a dial mountain angle 5 and a needle cylinder angle 6, etc.; since the circle transfer device is the same as the above-mentioned embodiment , so it will not be repeated;

[0038] Place the regular needle 1 and transfer needle 2 in a predetermined position (such as Figure 4 Shown), ready to move circle action;

[0039] Then promote this regular needle 1 to move forward, make the first yarn ring (old yarn ring) A push aside the first needle latch 13 (as Figure 5 shown), prepare to remove the second yarn ring (new yarn ring) B;

[0040] Then make this first yarn ring A stay in the first needle hook 12, and regular needle 1 is moved forward (as Image 6 Sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com