High-strength fastening fit connecting piece for ship

A technology of fastening connection and mating connection, which is applied in the direction of hull parts, hull, ship construction, etc., can solve the problem of single assembly method, and achieve the effects of good structural strength, simplified operation and strong convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

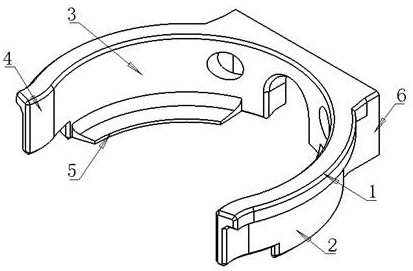

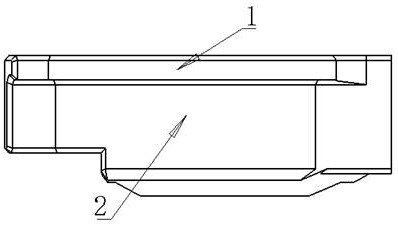

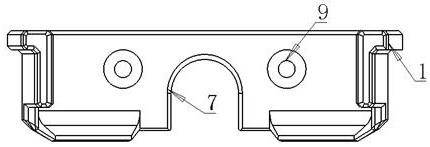

[0021] Such as Figure 1 to Figure 7 As shown, a high-strength marine fastening and fitting connector adopts a new structural design and is processed by an integral molding production method as a whole. , and then through the close connection of the main body position and the assembly structure in the up and down direction, it can make the assembly more convenient and solve the problem of single traditional assembly method. , not only can be used as an overall fixed installation structure, but also can be used for assembly and connection of more matching components through the lower end of this position, so that it can replace the traditional installation of various accessories, simplify the operation of installation and connection, and make the whole in assembly The efficiency in the connection process is higher, which can effectively guarantee the durability of the hull during use after assembly. It includes a cylindrical main body assembly stable fastening connection seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com