Multifunctional while-drilling engineering parameter measuring system and measuring method

A technology of engineering parameters and measurement systems, applied in the directions of measurement, earthwork drilling, borehole/well components, etc., can solve the problems of increasing failure rate and interference, increasing the length of drilling tools, single parameters, etc., and achieves high versatility and the effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The technical solution of the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

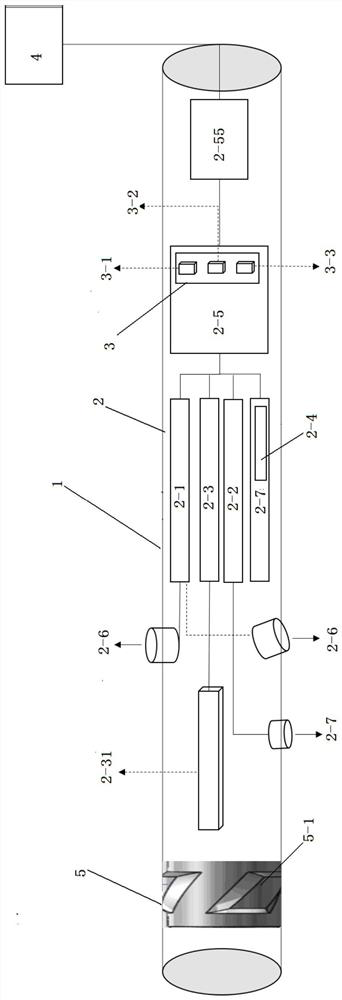

[0059] Such as figure 1 As shown, the present invention is a multifunctional engineering parameter measurement system while drilling, and the multifunctional engineering parameter measurement system while drilling includes:

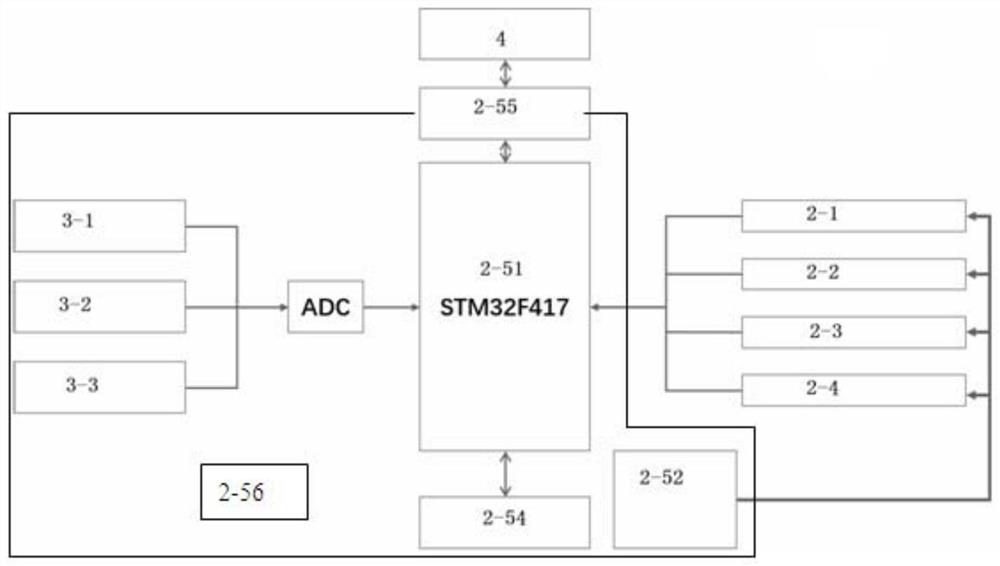

[0060] The engineering parameter measurement unit 2 is used to collect the real-time data of well diameter, formation resistivity, mud pressure and vibration during construction;

[0061] The working attitude and orientation measurement unit 3 is used to collect the working attitude and orientation data of the instrument during the real-time construction process;

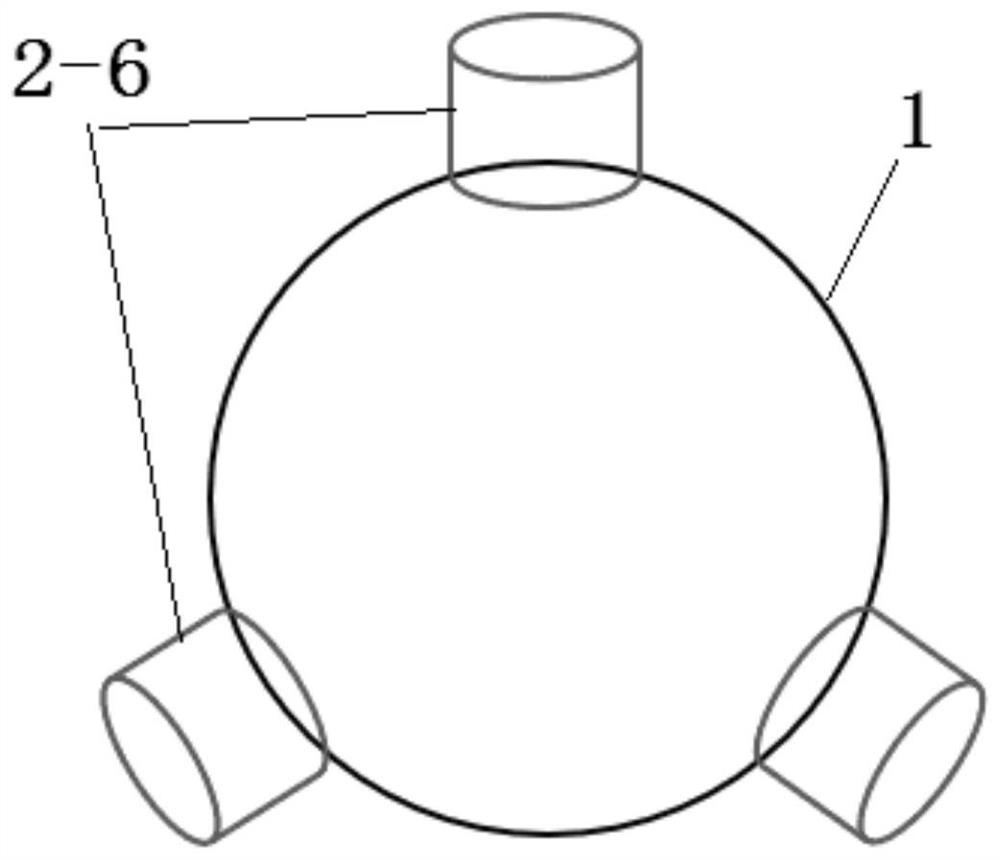

[0062] Mechanical steel collar structure 1, used to install and protect the engineering parameter measurement unit and the working attitude and orientation measurement unit, and improve the accuracy of measurement data;

[0063] The upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com