Fuel cell membrane electrode sealing frame

A fuel cell membrane and fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of reducing fuel cell energy utilization efficiency, difficult membrane electrode consistency, personnel and equipment threats, etc., to improve assembly efficiency. And the effect of assembly quality, reducing repeated disassembly and assembly for maintenance, and improving efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

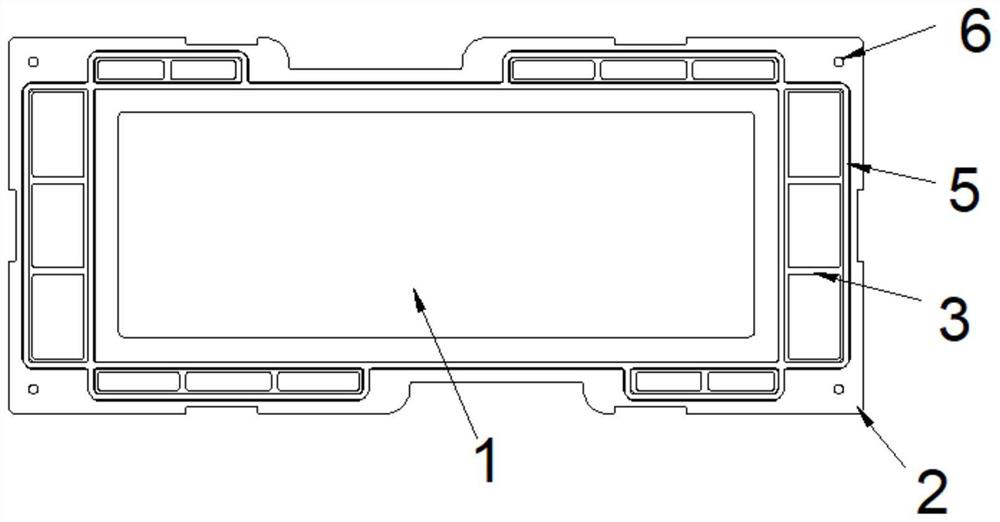

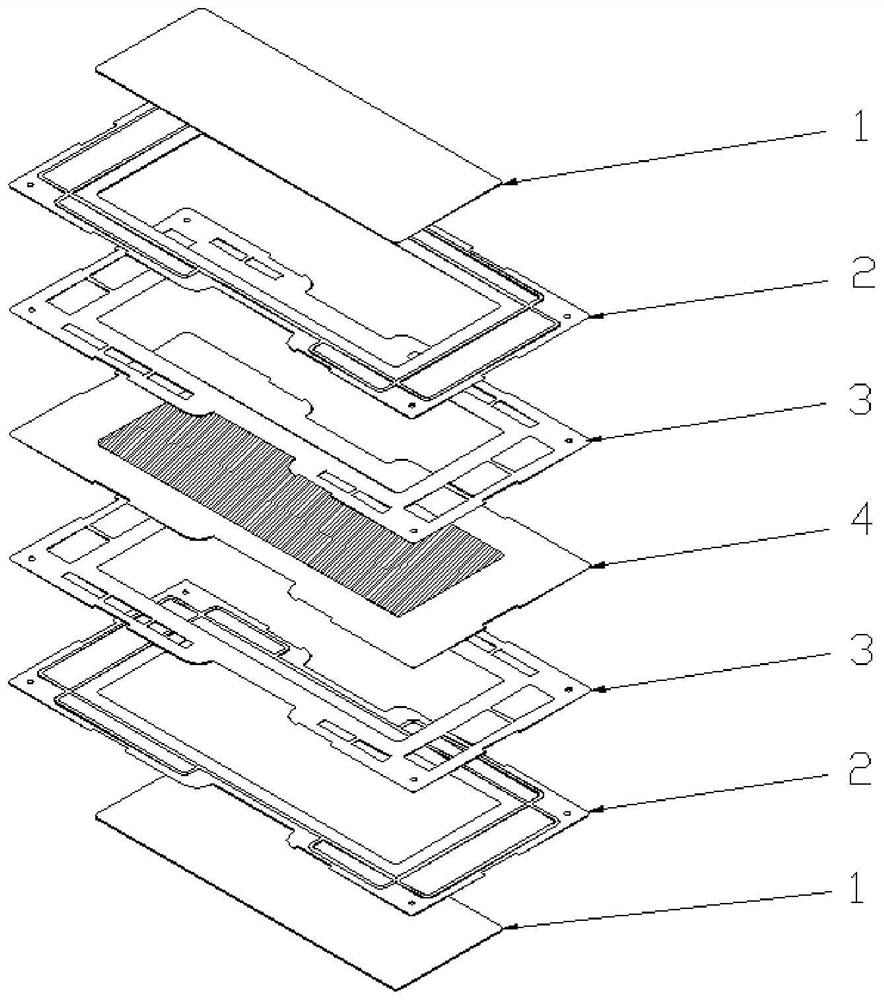

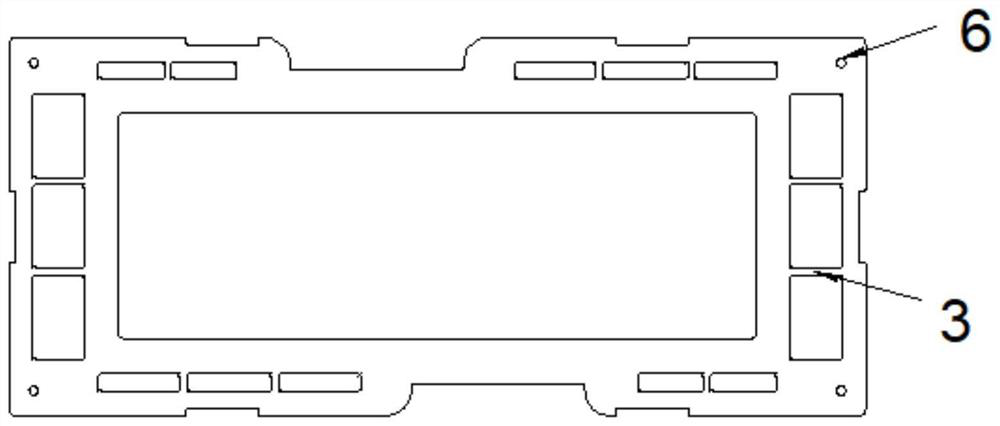

[0045] A fuel cell membrane electrode sealing frame, such as Figure 1~5 As shown, it includes a sub-sealing frame 3 and a supporting frame 2; the two sides of the CCM membrane 4 are respectively provided with a sub-sealing frame 3, a supporting frame 2, and a bipolar plate 7, and the carbon paper 1 is embedded in the membrane electrode sealing frame and covers the CCM membrane. 4; the total thickness of the sub-sealing frame 3 and the support frame 2 on one side of the CCM film 4 is equal to the total thickness of the compressed carbon paper 1 on one side of the CCM film 4 .

[0046] More specifically, in this embodiment:

[0047] The sub-sealing frame 3 can be a film made of PEN, PI or PET, with a thickness of 35-50 μm. In this embodiment, a PEN film is preferably selected, and its thickness is 35 μm. It is arranged close to the CCM film 4, and a support frame is arranged on it 2. Make the total thickness of the sub-seal frame 3 plus the support frame 2 equal to the total t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com