Piezoresistive sensor based on conductive hydrogel double-tower spring structure, preparation method and application

A conductive hydrogel and piezoresistive sensor technology, applied in the field of sensors, can solve problems such as detrimental installation, impact on viewing, large area, etc., and achieve the effects of simple production method, simple production, and great application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

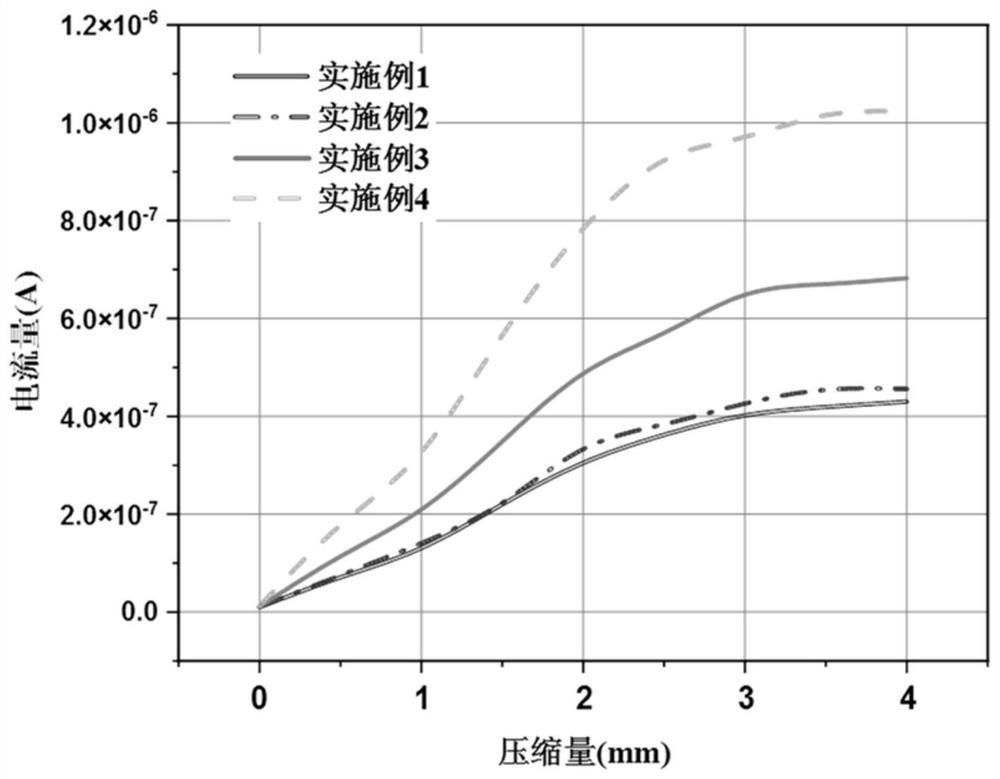

Embodiment 1

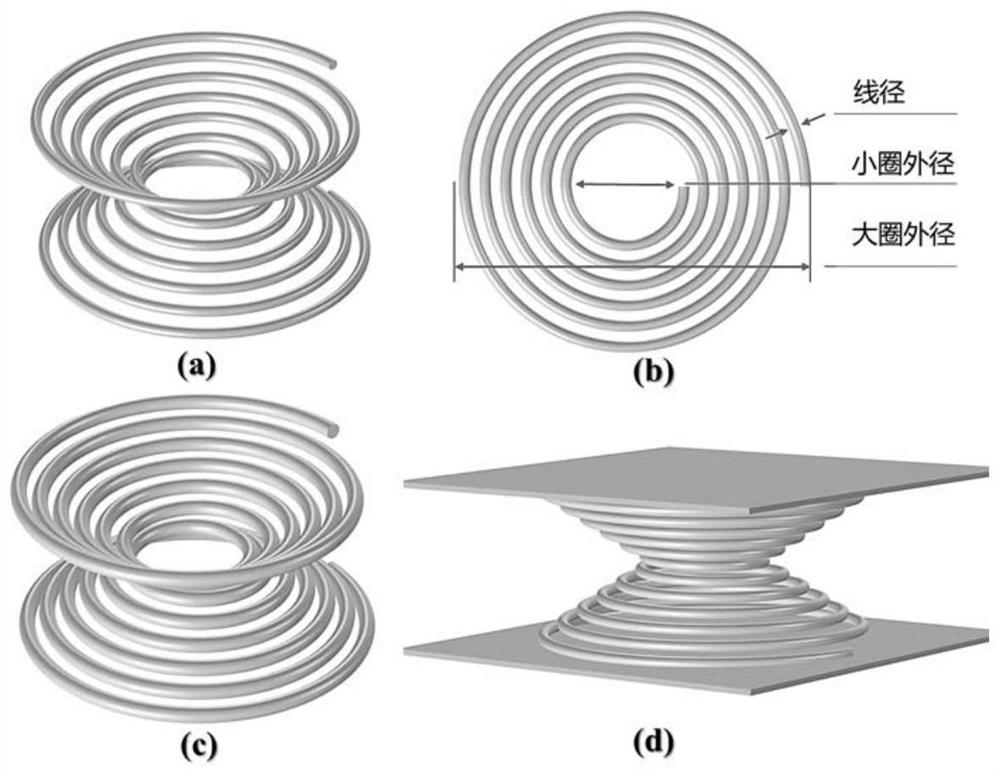

[0027] 1. The spring body of the double-tower spring structure is a spiral double-tower structure, and the shape is that the small diameter ends of the two tower-shaped springs are connected. The whole spring is wound by a spring wire, and the wire diameter of the spring body is 0.3 mm, the small outer diameter is 4mm, the largest outer diameter is 10mm, the radial pitch is 0.5mm, the axial pitch is 0.5mm, and the total number of coils is 12.

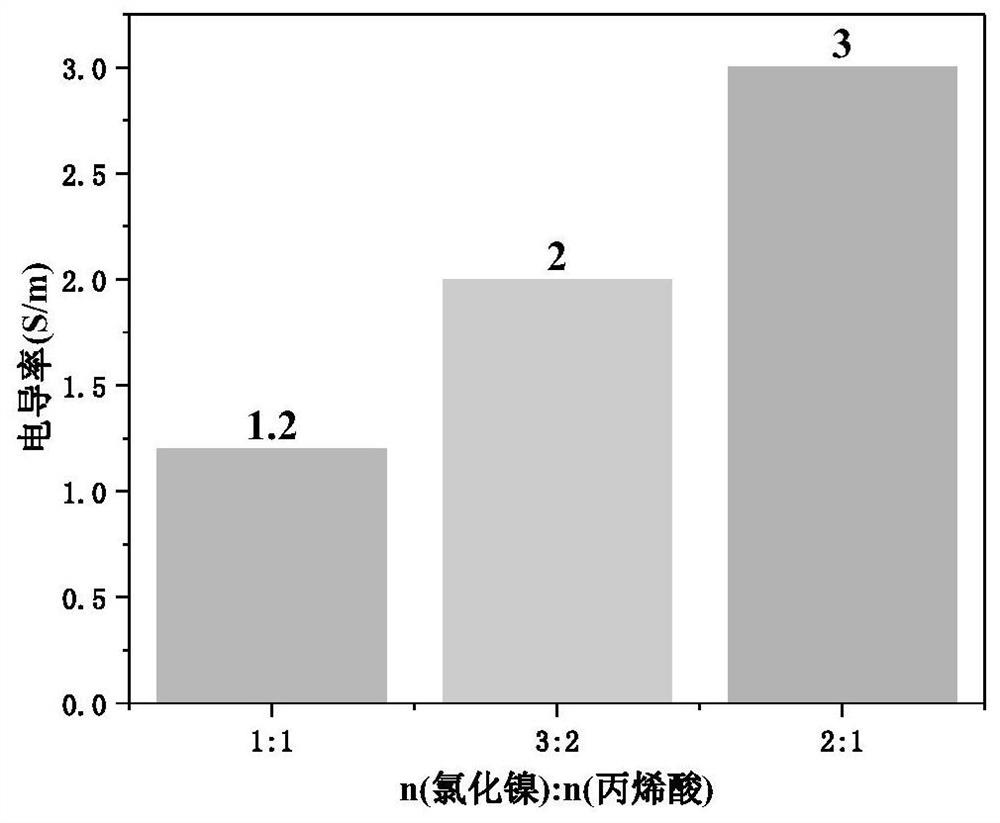

[0028] 2. Weigh 2g of acrylamide, 2g of acrylic acid, and 3.7g of nickel chloride hexahydrate, put them in a beaker a filled with 10mL of deionized water to dissolve, add a magnet and stir on a magnetic stirrer until the solids are completely dissolved; then in the above Add 0.008g of N,N-methylenebisacrylamide powder into the solution, drop into 0.4mL of tetramethylethylenediamine solution, stir magnetically again until all the solids are dissolved; put the prepared solution into a vacuum drying oven to drain Air for 10 minutes. Weigh...

Embodiment 2

[0033] 1. The spring body of the double-tower spring structure is a spiral double-tower structure, and the shape is that the small diameter ends of the two tower-shaped springs are connected. The whole spring is wound by a spring wire, and the wire diameter of the spring body is 0.3 mm, the small outer diameter is 4mm, the largest outer diameter is 10mm, the radial pitch is 0.5mm, the axial pitch is 0.5mm, and the total number of coils is 12.

[0034] 2. Weigh 2g of acrylamide, 2g of acrylic acid, and 3.7g of nickel chloride hexahydrate, put them in a beaker a filled with 10mL of deionized water to dissolve, add a magnet and stir on a magnetic stirrer until the solids are completely dissolved; then in the above Add 0.008g of N,N-methylenebisacrylamide powder into the solution, drop into 0.4mL of tetramethylethylenediamine solution, stir magnetically again until all the solids are dissolved; put the prepared solution into a vacuum drying oven to drain Air for 10 minutes. Weigh...

Embodiment 3

[0039] 1. The spring body of the double-tower spring structure is a spiral double-tower structure, and the shape is that the small diameter ends of the two tower-shaped springs are connected. The whole spring is wound by a spring wire, and the wire diameter of the spring body is 0.3 mm, the small outer diameter is 4mm, the largest outer diameter is 10mm, the radial pitch is 0.5mm, the axial pitch is 0.5mm, and the total number of coils is 12.

[0040] 2. Weigh 2g of acrylamide, 2g of acrylic acid, and 5.54g of nickel chloride hexahydrate, and dissolve them in a beaker a filled with 10mL of deionized water, add magnets and stir on a magnetic stirrer until the solids are completely dissolved; then in the above Add 0.008g of N,N-methylenebisacrylamide powder into the solution, drop into 0.4mL of tetramethylethylenediamine solution, stir magnetically again until all the solids are dissolved; put the prepared solution into a vacuum drying oven to drain Air for 10 minutes. Weigh 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com