System and method for continuous microwave hydrothermal treatment of dioxins in incineration fly ash

A microwave hydrothermal method and fly ash incineration technology, applied in the field of fly ash disposal, can solve the problems of temperature and mechanical alternating stress that cannot meet the requirements of processing materials, difficult to accurately measure the relevant parameters of the reaction system, and high field strength requirements. Problems such as the inability to realize working conditions, to achieve the effect of high resource utilization potential, easy continuous control, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

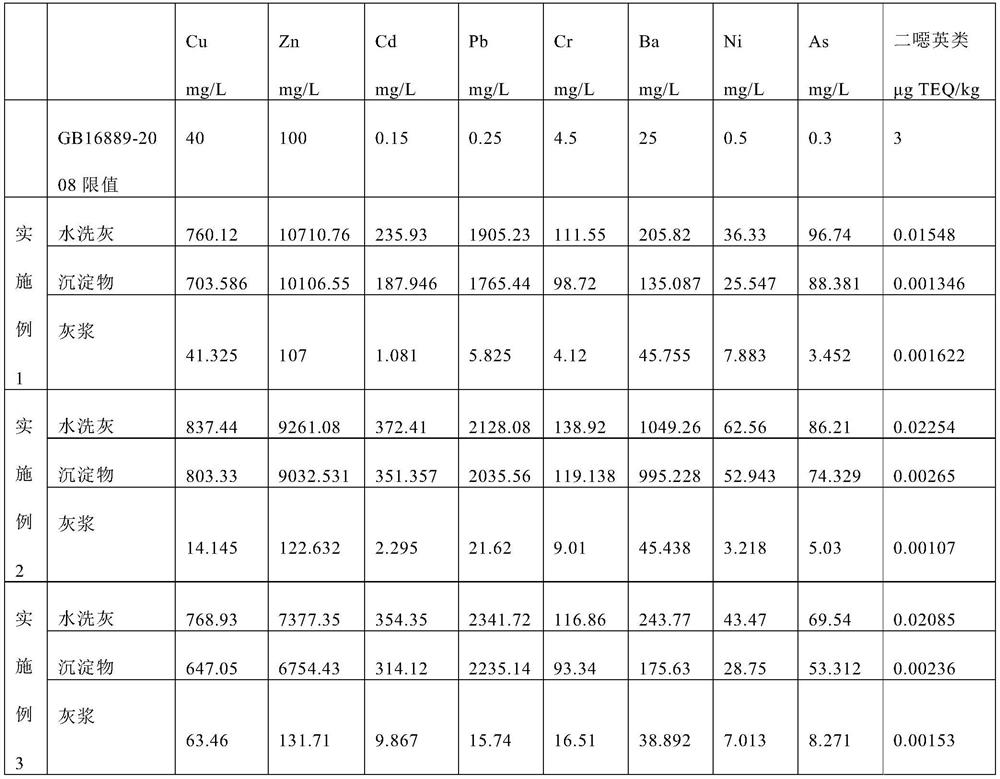

[0058] The water-washed ash in the present embodiment is the incineration fly ash of dechlorination treatment, and its dioxin and some heavy metal element contents are as shown in Table 1;

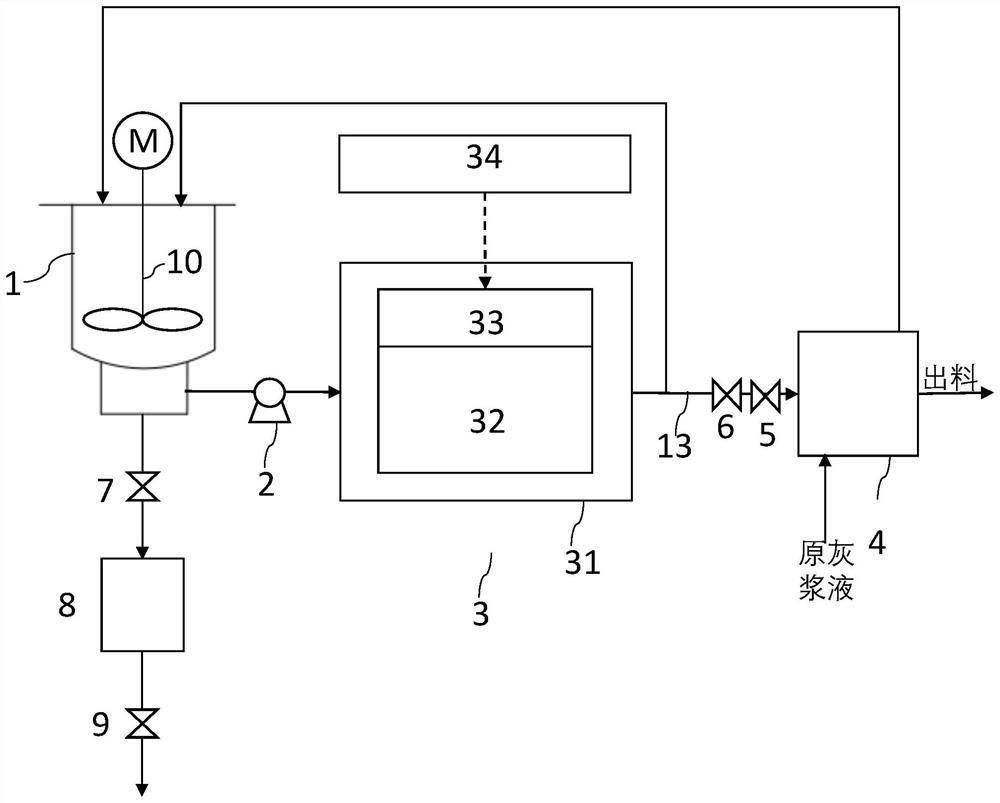

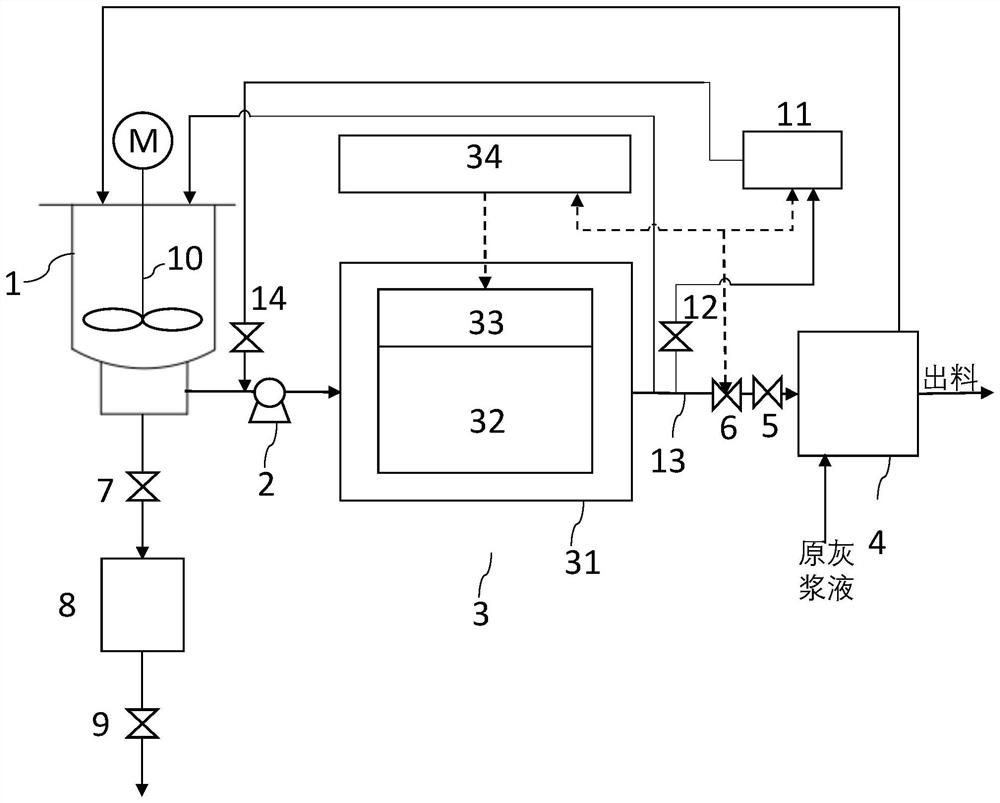

[0059] The continuous microwave hydrothermal method of the present embodiment handles the process of dioxins in the incineration fly ash as follows:

[0060] (1) adding water to the incineration fly ash after the dechlorination treatment is made into a raw ash slurry with a solid content of 15wt%;

[0061] (2) After the raw ash slurry is preheated by the heat exchange device, the temperature reaches 65 °C, and then enters the buffer stirring tank and is stirred to obtain a pretreated slurry. The pretreated slurry enters the microwave reaction device through a circulating pump for microwave heating. Treatment to obtain a circulating slurry, wherein the stirring speed is 120 rpm, the microwave heating treatment temperature is 110 ° C, and the microwave heating treatment pressure is 0.12-2 MP...

Embodiment 2

[0065] The water-washed ash in the present embodiment is the incineration fly ash of dechlorination treatment, and its dioxin and some heavy metal element contents are as shown in Table 1;

[0066] The continuous microwave hydrothermal method of the present embodiment handles the process of dioxins in the incineration fly ash as follows:

[0067] (1) adding water to the incineration fly ash after the dechlorination treatment is made into a raw ash slurry with a solid content of 20wt%;

[0068](2) After the raw ash slurry is preheated by the heat exchange device, the temperature reaches 50 ° C, and then enters the buffer stirring tank and is stirred to obtain a pretreated slurry. The pretreated slurry enters the microwave reaction device through a circulating pump for microwave heating. Treatment to obtain circulating slurry, wherein the stirring speed is 120 rpm, the microwave heating treatment temperature is 150 ° C, and the microwave heating treatment pressure is 0.12-2 MPa,...

Embodiment 3

[0072] The water-washed ash in the present embodiment is the incineration fly ash of dechlorination treatment, and its dioxin and some heavy metal element contents are as shown in Table 1;

[0073] The continuous microwave hydrothermal method of the present embodiment handles the process of dioxins in the incineration fly ash as follows:

[0074] (1) adding water to the incineration fly ash after the dechlorination treatment is made into a raw ash slurry with a solid content of 25wt%;

[0075] (2) After the raw ash slurry is preheated by the heat exchange device, the temperature reaches 45 °C, and then enters the buffer stirring tank and is stirred to obtain a pretreated slurry. The pretreated slurry enters the microwave reaction device through a circulating pump for microwave heating. Treatment to obtain circulating slurry, wherein the stirring speed is 120 rpm, the microwave heating treatment temperature is 105-200 ° C, and the microwave heating treatment pressure is 0.12-2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com