Positioning and cutting device for decorative plate processing

A technology for positioning, cutting, and decorating sheets, applied in metal processing and other directions, can solve the problems of inability to perform cutting processing, position height adjustment, etc., and achieve the effects of improving adjustment reliability, reducing sintering, and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

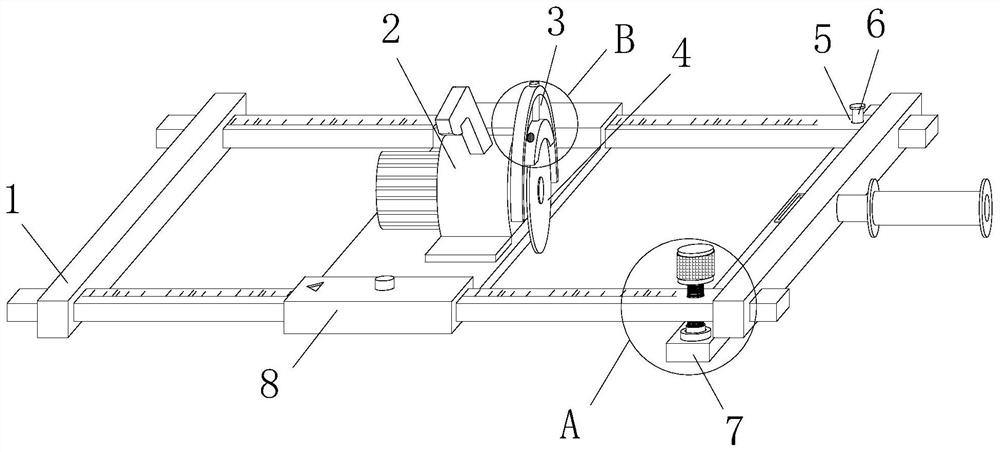

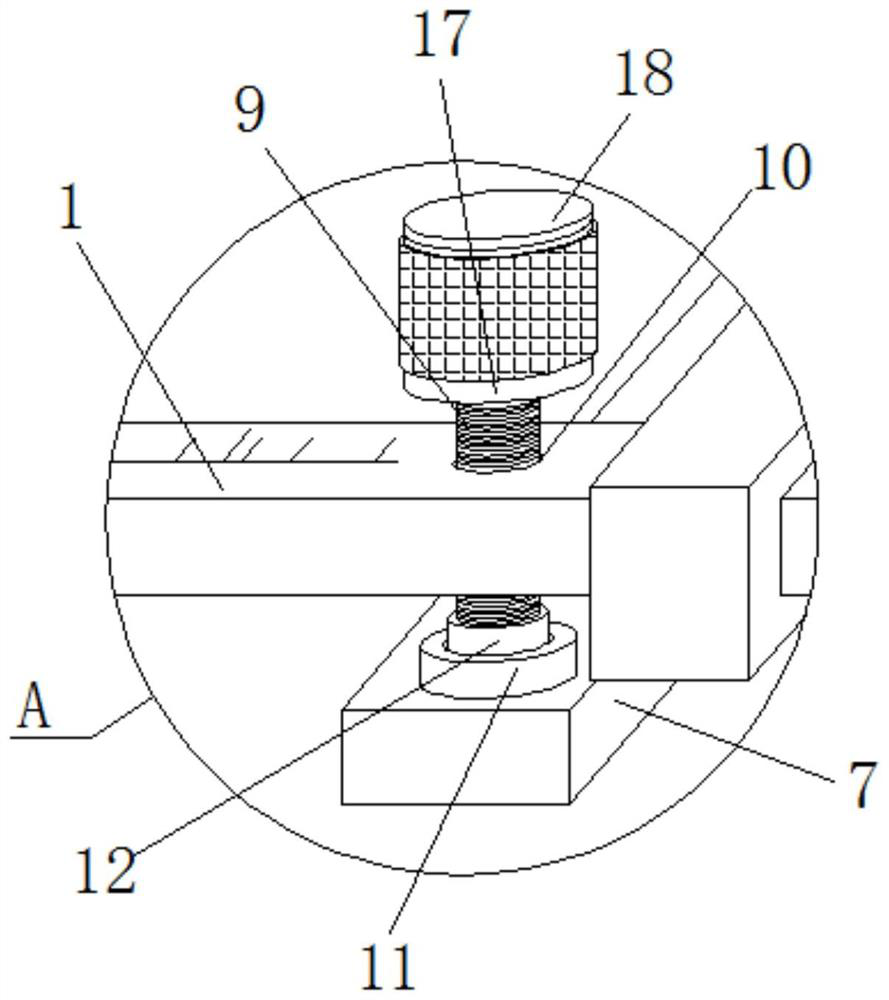

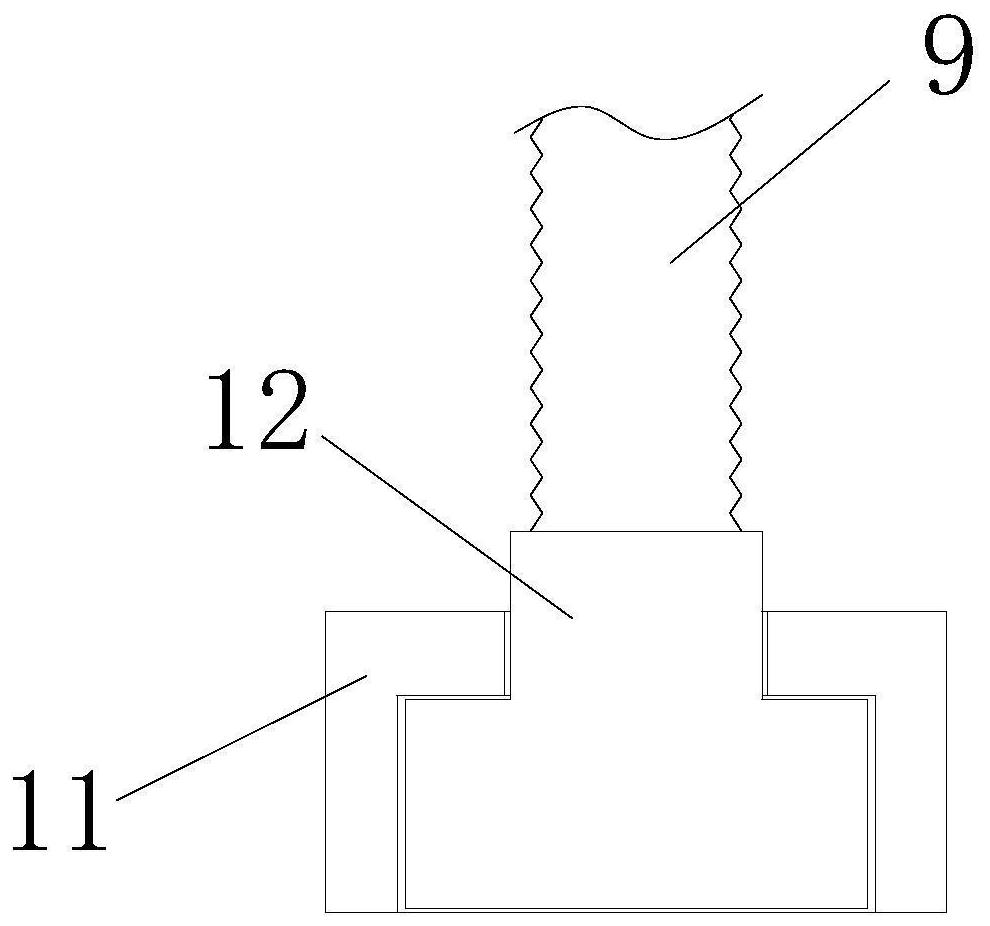

[0026] see figure 1 , figure 2 , image 3 and Figure 6 , the present invention provides a technical solution: a positioning and cutting device for processing decorative plates, including a positioning frame 1, an adjusting slide seat 8 is slidably connected to the positioning frame 1, through the designed adjusting slide seat 8 and positioning frame 1, the adjustment The sliding seat 8 realizes horizontal sliding adjustment on the positioning frame 1 to ensure that the device realizes positioning and cutting, making the cutting more accurate and reliable. The surface of one end of the adjusting sliding seat 8 is fixed with a cutting body 2, and one end of the cutting body 2 is fixed with sawtooth Sheet 4, the bottom of one end of the positioning frame 1 is provided with a horizontal side plate 7, and the top of one end of the horizontal side plate 7 is provided with a connecting sleeve 12. Through the designed connecting sleeve 12, adjusting stud 9 and connecting sleeve 11...

Embodiment 2

[0029] see Figure 1 to Figure 6, the present invention provides a technical solution: a positioning and cutting device for processing decorative plates, including a positioning frame 1, an adjusting slide seat 8 is slidably connected to the positioning frame 1, through the designed adjusting slide seat 8 and positioning frame 1, the adjustment The sliding seat 8 realizes horizontal sliding adjustment on the positioning frame 1 to ensure that the device realizes positioning and cutting, making the cutting more accurate and reliable. The surface of one end of the adjusting sliding seat 8 is fixed with a cutting body 2, and one end of the cutting body 2 is fixed with sawtooth Sheet 4, the bottom of one end of the positioning frame 1 is provided with a horizontal side plate 7, and the top of one end of the horizontal side plate 7 is provided with a connecting sleeve 12. Through the designed connecting sleeve 12, adjusting stud 9 and connecting sleeve 11, the connecting Sleeve 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com