Resin stirrer with stable lifting device

A mixer and resin technology, applied in the field of mixing equipment, can solve the problems of increasing the weight of the overall equipment, which cannot be solved perfectly, and affects work efficiency, etc., and achieve the effect of light weight, strong continuity and stability, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

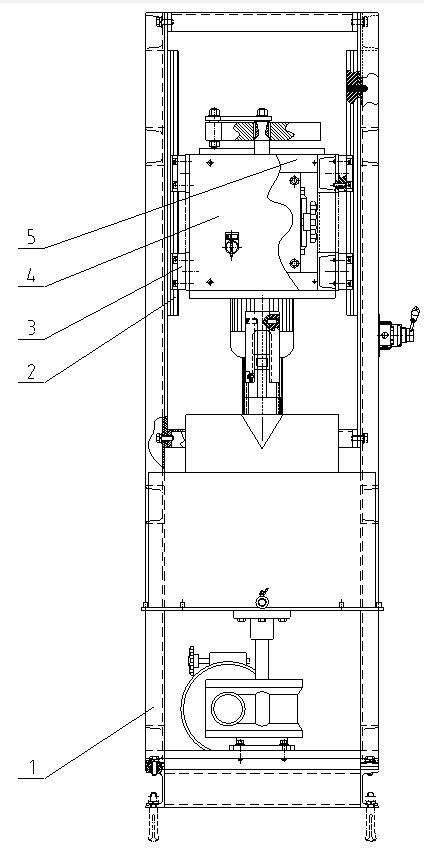

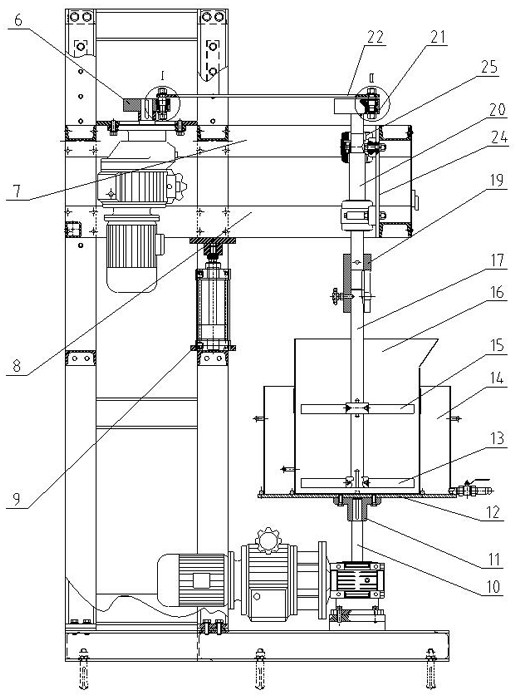

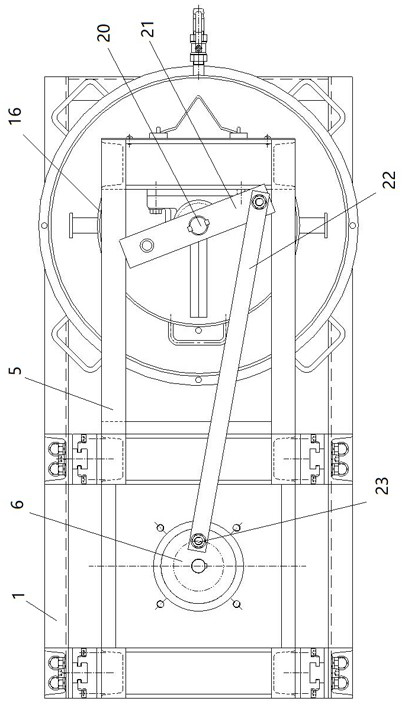

[0030] See attached Figure 1-5 , the resin mixer with a stable lifting device disclosed in the present invention is suitable for mixing various materials, especially for mixing materials at a lower speed such as resin. The stable lifting of the stirring shaft mechanism is realized by adding a double-layer lifting frame.

[0031] The present invention is described by taking a resin mixer as an example, including a main frame 1 of the mixer, a stirring shaft mechanism, and a mixing barrel mechanism. The stirring shaft mechanism is arranged on the main frame 1, and the stirring barrel mechanism is arranged on the side of the main frame 1, and also includes a lifting mechanism and a rotating mechanism. The stirring shaft mechanism is installed on the lifting mechanism, and the lifting mechanism drives the stirring shaft mechanism to move up and down; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com