Screw ejection device of rubber extruder

A machine screw and rod top technology, which is applied in the field of tire manufacturing, can solve the problems of reducing the service life of the equipment, the screw cannot be rotated, and cannot be disassembled normally, so as to improve production efficiency and avoid disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

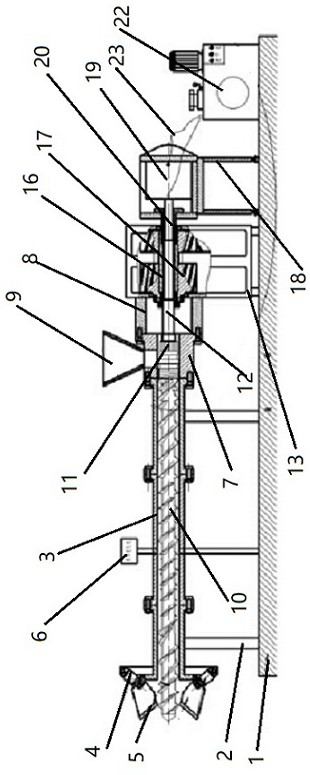

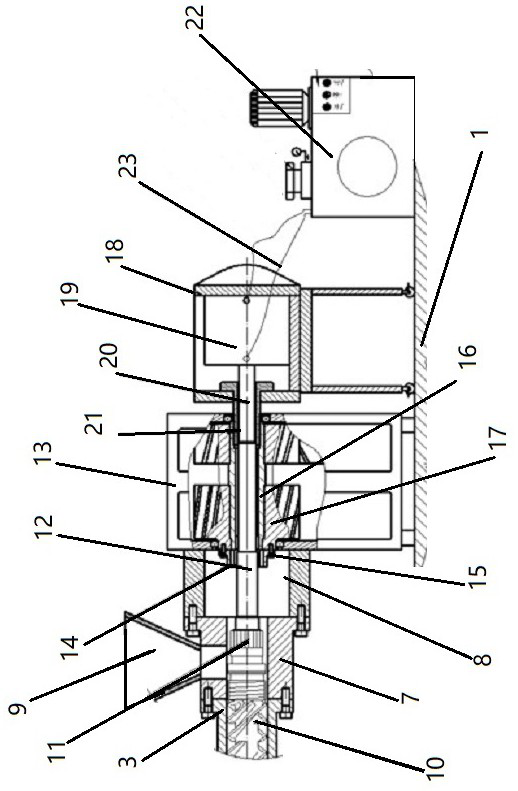

[0011] like figure 1 and figure 2 , is provided with installation platform 1, and body support 2 is installed on the upper end of installation platform 1, and organic barrel 3 is installed on the upper end of body support 2, and an oil cylinder 4 is respectively installed at the upper and lower ends of the opening on the left side of machine barrel 3, and the telescoping rod end of oil cylinder 4 They are respectively connected with a lock head 5 via a hinge shaft, an operation control cabinet 6 is installed on the upper end of the machine barrel 3, a feeding box 7 and a connection box 8 are fixedly installed on the right side of the machine barrel 3 in turn, and the right side of the connection box 8 is connected with the gear box 13, and the machine A screw 10 is installed inside the cylinder 3, the right end of the screw 10 is located in the feeding box 7, the upper end of the feeding box 7 is provided with a feeding port 9, the right end of the screw 10 is equipped with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com