Spring pre-tightening type hydraulic floating tailstock

A spring seat, preloading technology, applied in the direction of tailstock/top, turning equipment, tool holder accessories, etc., can solve problems such as affecting machining accuracy, workpiece bending, and inability to self-adjust, to improve quality, eliminate The effect of deformation and bending of the workpiece to ensure the machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

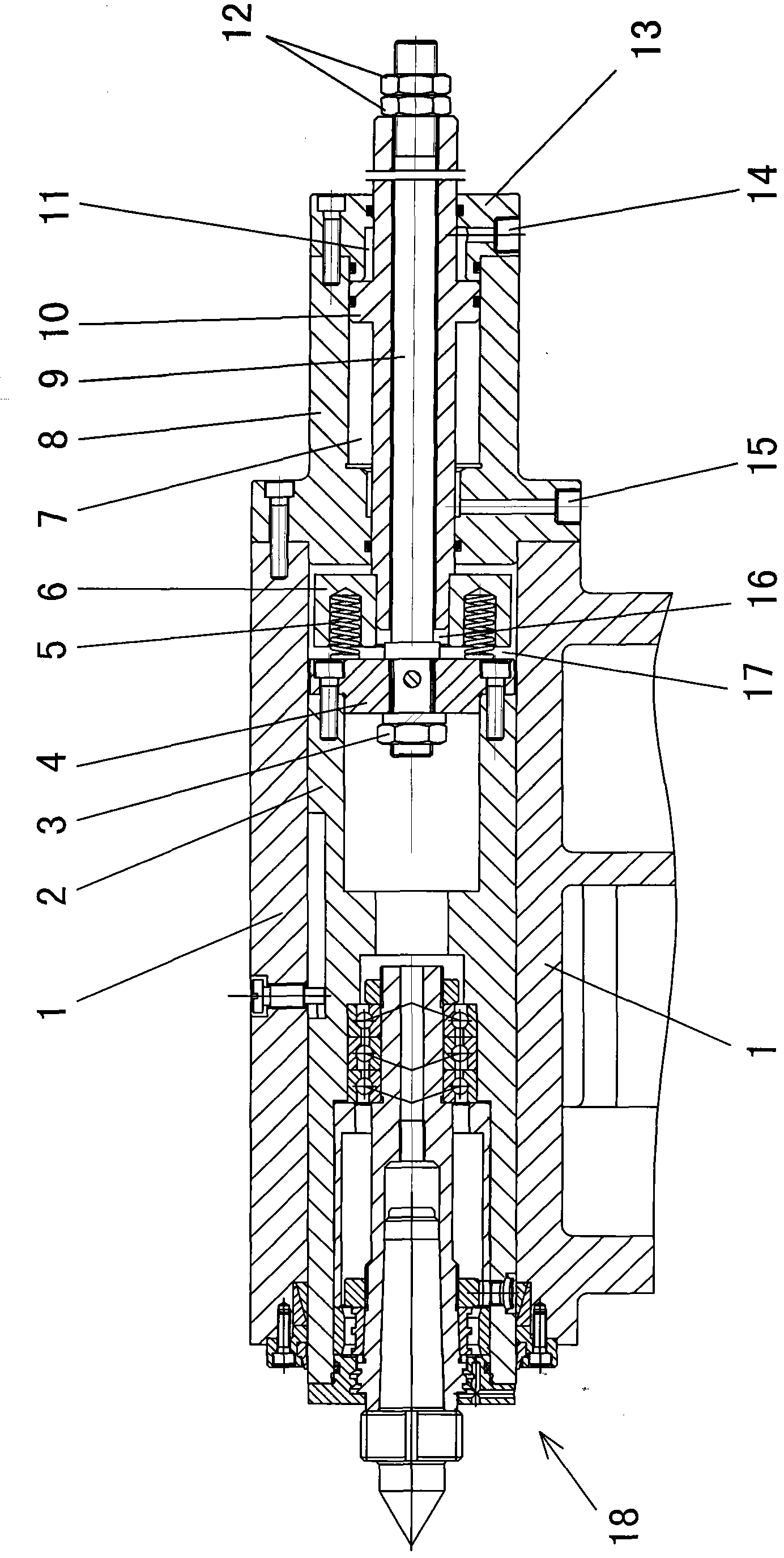

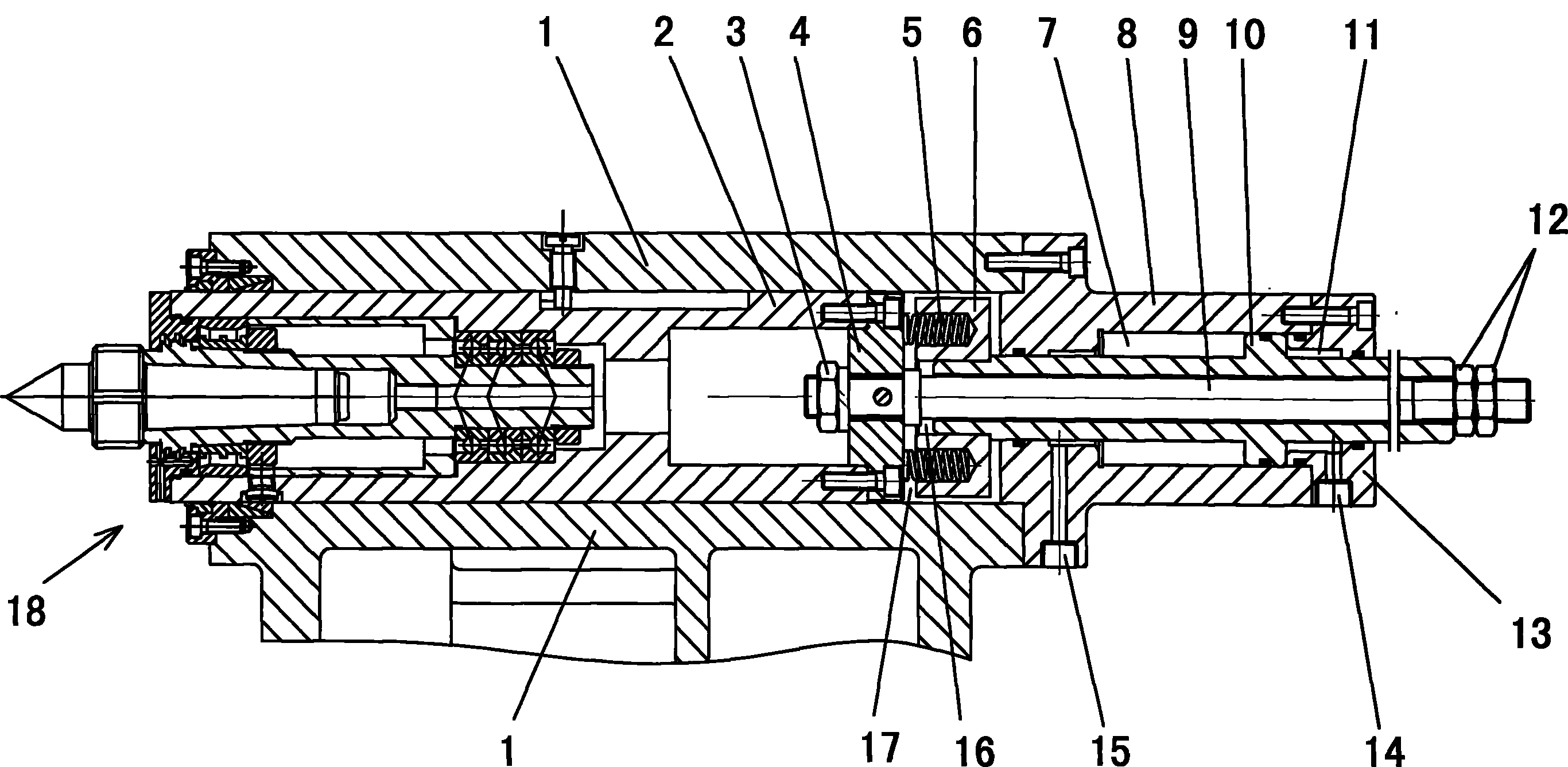

[0007] Such as figure 1 Shown: 1 is tailstock body, and sleeve 2 is equipped with in the inboard of tailstock body 1, and top mechanism 18 is equipped with in the front part of sleeve 2 inner sides. The rear end of the tailstock body 1 is fixed with an oil cylinder 8 by bolts, the inner cavity of the oil cylinder 8 is equipped with a piston 10, the front part of the piston 10 forms a front oil chamber 7 and communicates with the front oil port 15 on the oil cylinder 8, the piston 10 The rear oil cavity 11 is formed and communicated with the rear oil port 14 on the oil cylinder 8 . The rear end of the sleeve 2 is fixedly connected with a rear cover 4 by bolts, and a pull rod 9 is arranged in the center hole of the piston 10. The front end of the pull rod 9 extends out of the piston 10 and is processed with bosses and threads, and is fastened by the rear cover. The nut 3 and the boss clamp the back cover 4. The front portion of the piston 10 protrudes out of the oil cylinder 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com