Debugging method of cooling water system for dry dock

A technology of cooling water system and debugging method, which is applied to ship parts, ships, transportation and packaging, etc., can solve problems such as debugging without docking stage, and achieve the effect of reducing the trial period and mooring time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

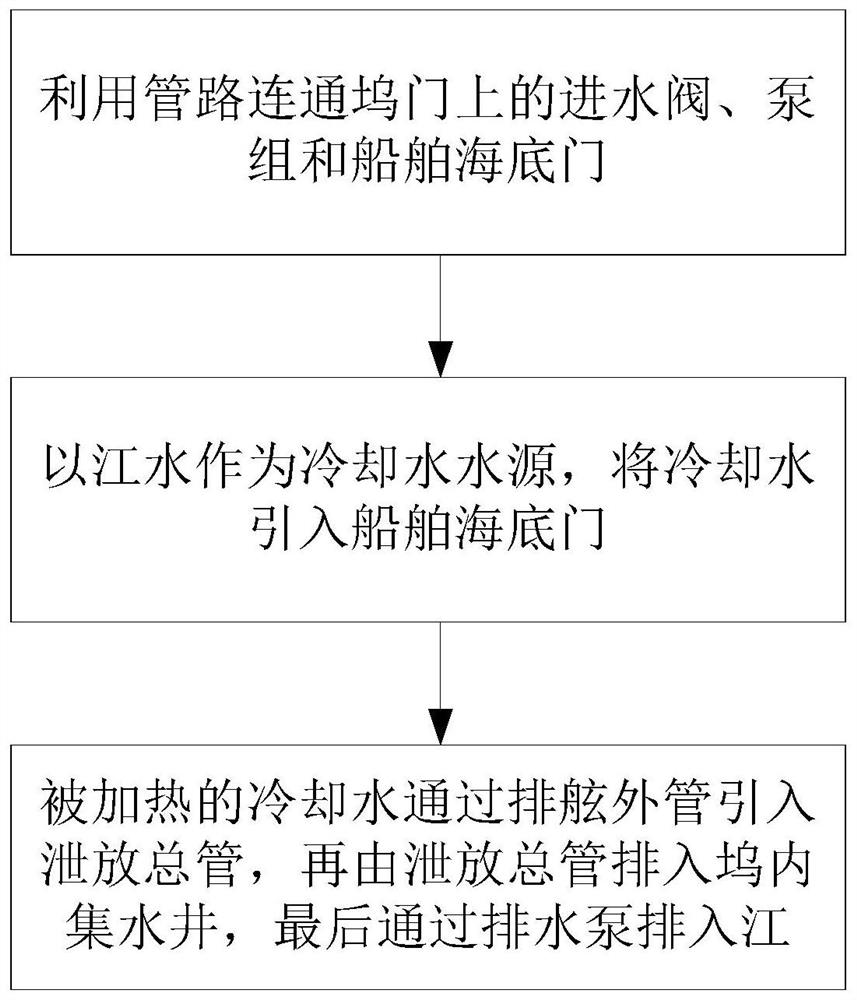

[0016] see figure 1 , dry dock cooling water system debugging method of the present invention, comprises the following steps:

[0017] Step 1, using pipelines to connect the water inlet valve on the dock door, the pump unit and the seabed door of the ship. That is: set several water inlet valves on the dock door of the dry dock, use branch pipes and butterfly valves to connect the water inlet valves and pump sets, and use branch pipes and butterfly valves to connect the pump sets to the ship's seabed door. The cooling water pump of the pump unit is installed at the bottom of the dock close to the left and right sides of the dock door, that is, installed below the lowest liquid level to ensure that the river water can flow into the pump cavity by itself.

[0018] Step 2, use river water as the cooling water source, and introduce the cooling water into the ship's seabed doo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com