Large-space ceiling soft film installation structure

A technology of installation structure and large space, which is applied in the direction of building components, building structure, construction, etc., can solve the problems of easy aging of plastics, complex installation structure, inconvenient disassembly and replacement of plugs, etc., and achieve excellent supporting capacity and simple installation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

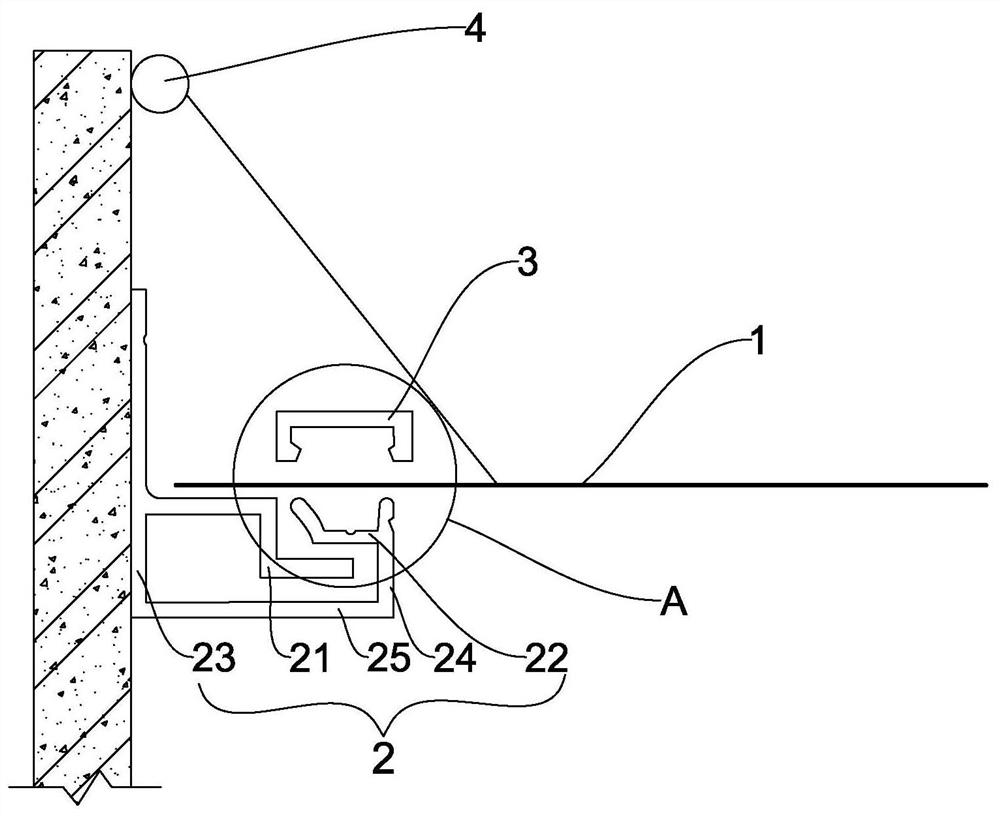

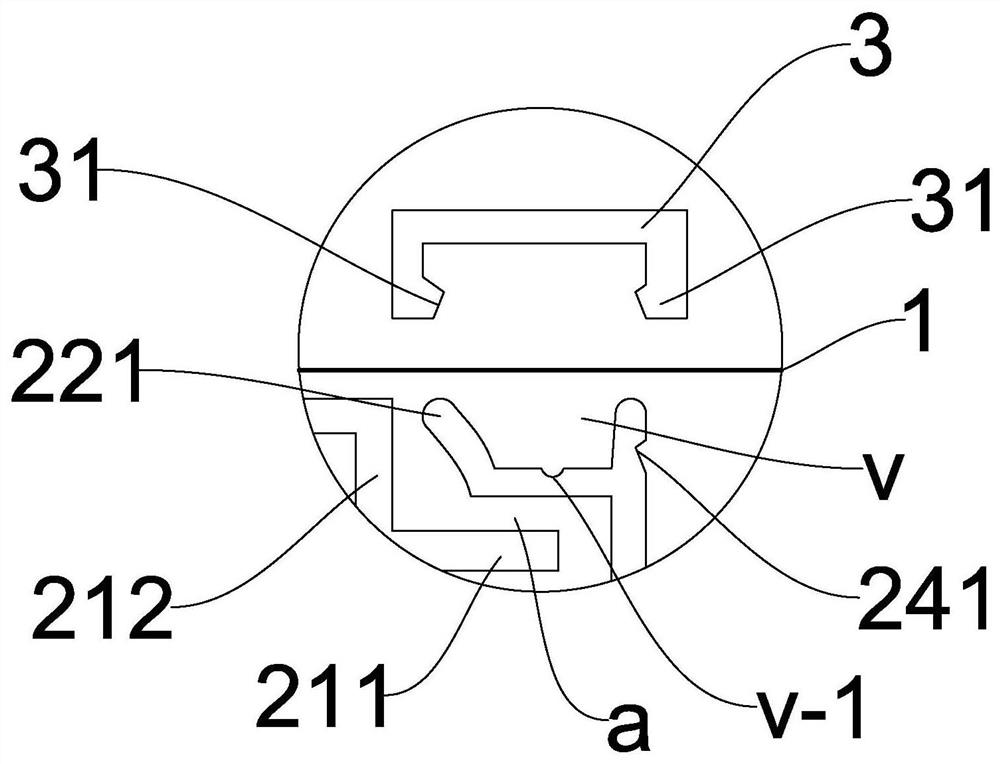

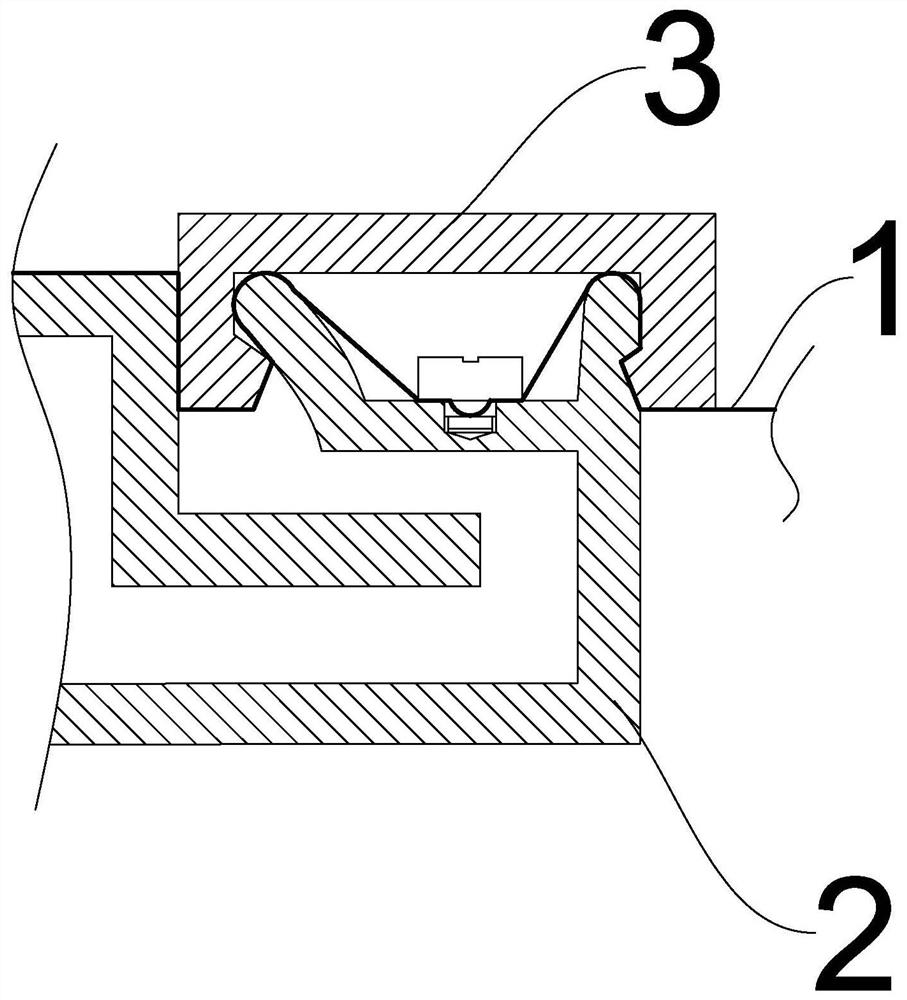

[0031] A large space ceiling soft film installation structure, please refer to figure 1 , including two installation components set at the same height and the soft membrane body 1 clamped and fixed by the two installation components. The installation components respectively clamp the two sides of the soft membrane body 1. The soft membrane body mentioned in this embodiment 1 is a large-space soft film with a relatively large weight, so the load-bearing of the installation structure is very important. The installation assembly in this embodiment includes a wall joist 2 and a buckle strip 3, and the wall joist 2 is composed of the first end panel 23, The second end panel 24, the auxiliary support cantilever 21, the elastic load-bearing cantilever 22 and the keel bottom plate 25 are composed, and the entire wall keel 2 is integrally formed; the first end panel 23 is set against the wall, and the second end panel 24 is set away from the wall. The first end panel 23 and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com