Method for rapidly cutting off internal outlet fault of controllable high-voltage reactor for line protection

A line protection and high-resistance technology, applied in emergency protection circuit devices, electrical components, etc., can solve the problem that the fault removal time does not meet the safety and stability requirements of the power system, and achieve the effect of fast action and fast action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present application will be further described below with reference to the accompanying drawings. The following examples are for more clearly explaining the technical solutions of the present invention without limiting the scope of the present application.

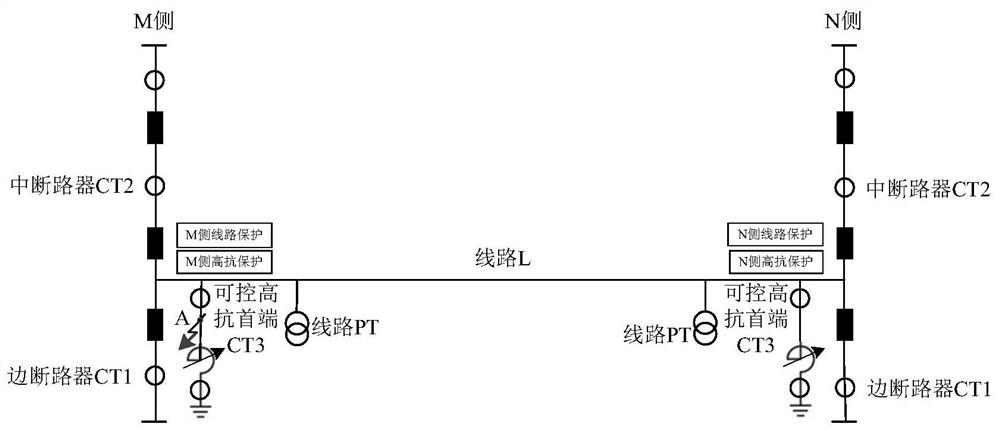

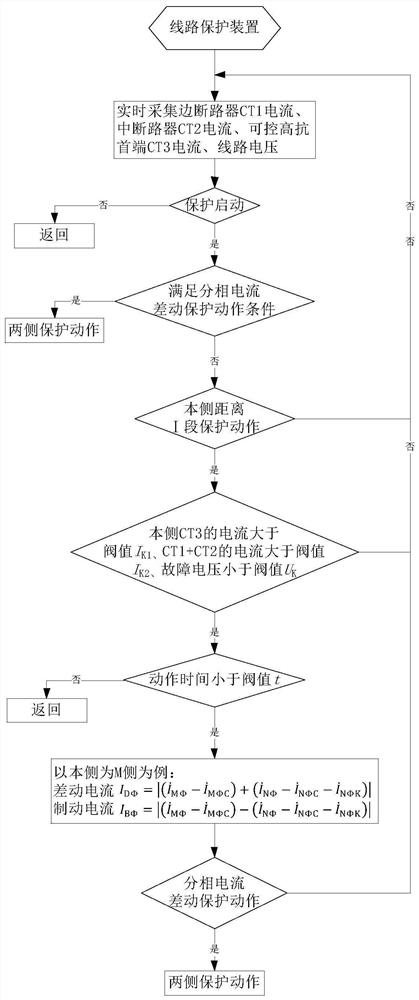

[0055]figure 1 A schematic diagram of the controllable high-resistance internal export failure. The use of controllable high resistance is currently 3 / 2 circuit breaker wiring for high voltage long lines. The line protection devices on both sides of the line collectively collect the current of the edge circuit breaker CT1, the current of the middle circuit breaker CT2, the current controllable high anti-first end CT3, and the voltage of the line PT.

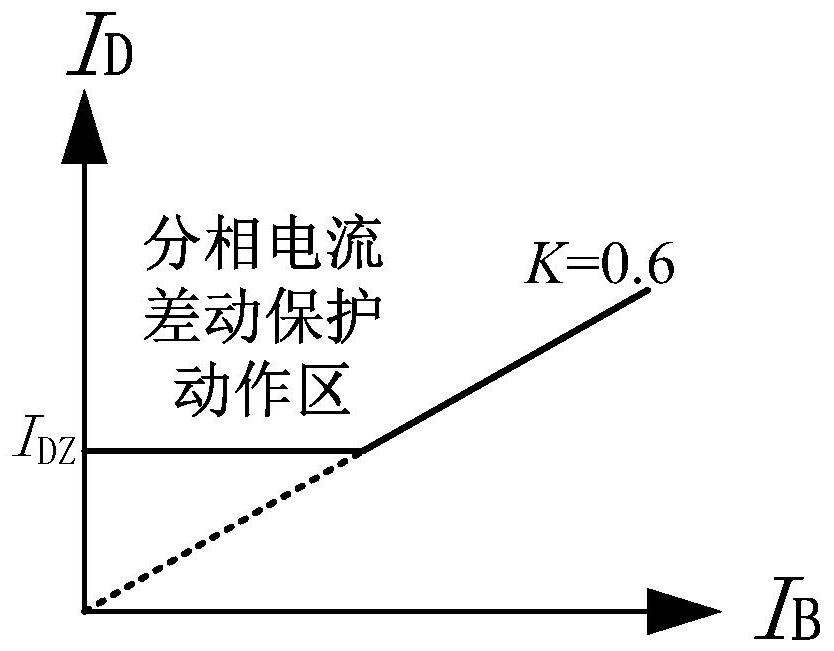

[0056] Line protection, high resistance protection is configured separately on both sides of the line. The main protection of line protection is a differential current difference, and the reserve protection is a distance protection, etc., and configures the functions su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com