Two-component screw-down valve

A screw valve, two-component technology, used in coatings, devices for coating liquids on surfaces, etc., can solve problems such as excessive glue output, inconsistent stator specifications, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

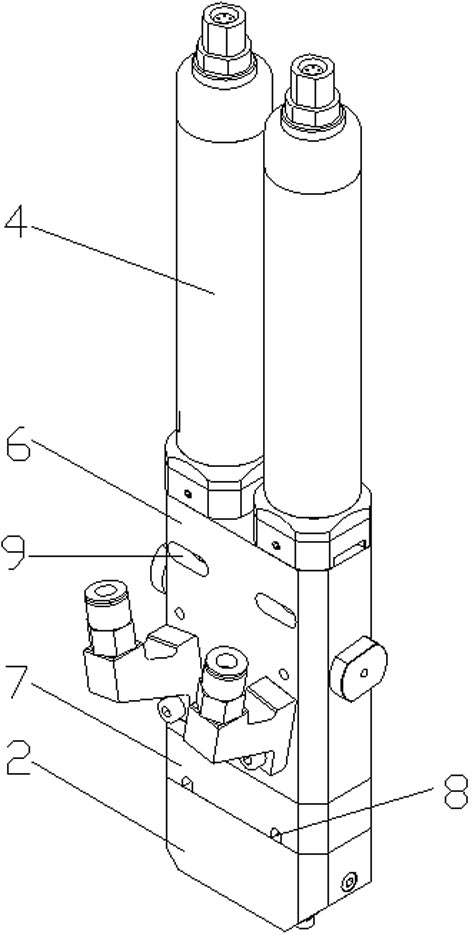

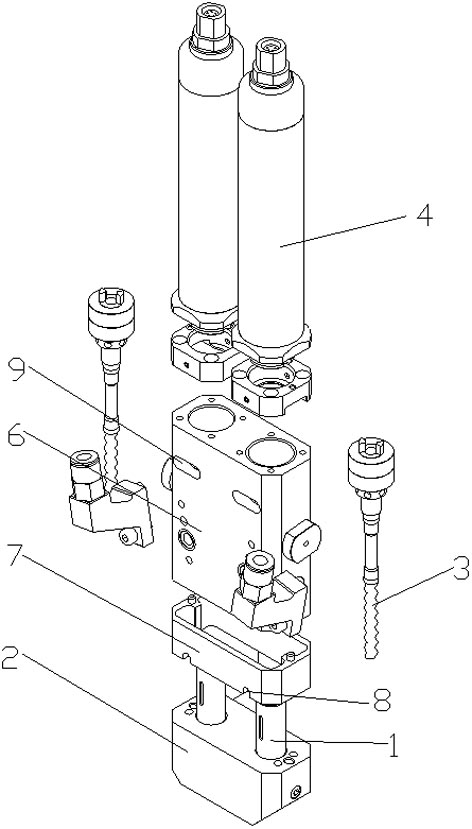

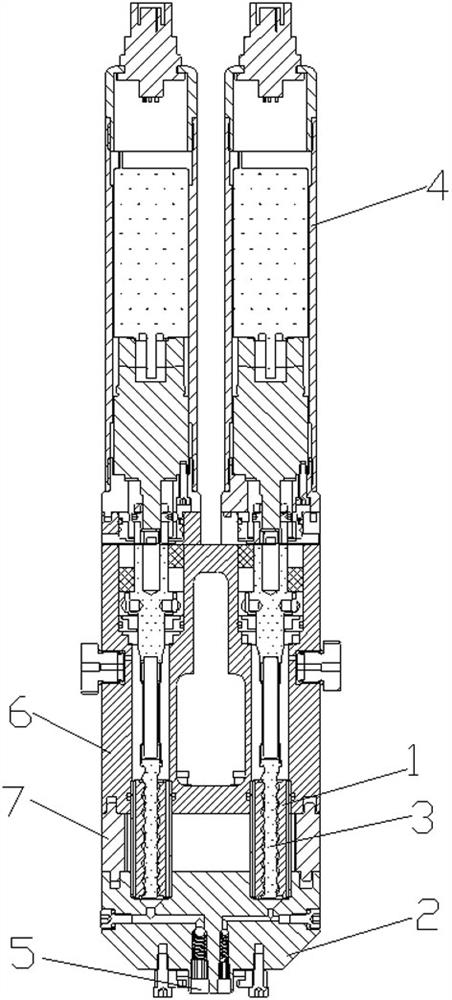

Image

Examples

Embodiment Construction

[0030] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0031] In view of the problem that the current two-component screw valve outlet pressure changes lead to uneven glue output, and even the glue cannot be released due to the curing of the glue in the mixing tube. There is realization. When the outlet pressure of the screw valve increases, the load of the rotor rotation inside the screw valve becomes larger, and the motor needs to increase the torque to maintain the controlled rotation of the rotor, and the torque of the motor is completely matched with the driving current of the motor. Based on the above analysis: the pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap