Upholstered furniture with integrated back rest portion webbing support

A technology of back support and backrest, which is applied in the integration of seat bag and rib plate support structure, the manufacture of furniture with seat cover, and the field of seat cover material panel support structure, which can solve the problems of cost and time consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

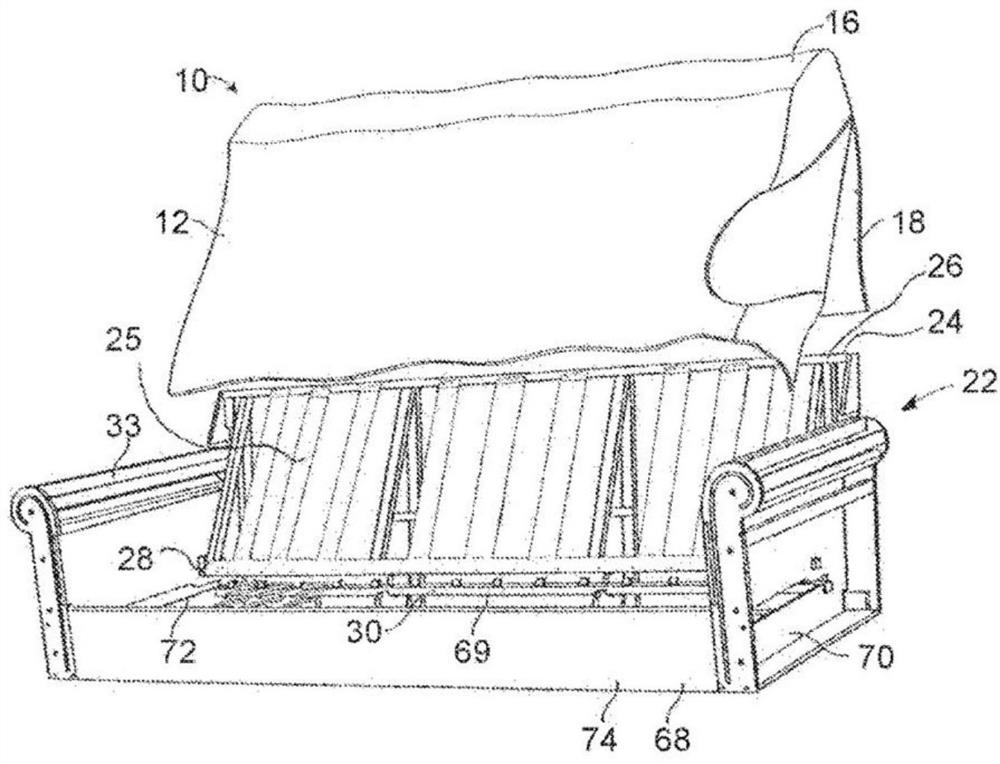

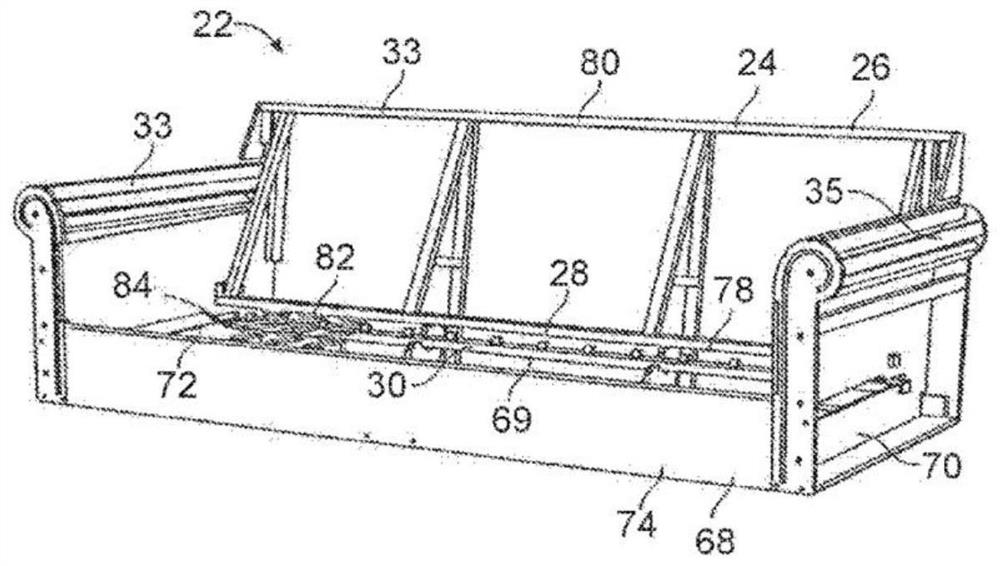

[0044] Figure 1 illustrates a prior art seat sleeve (SACK) having a first material panel 14, a top material panel 16, a back material panel 18, and a side material panel 20. The seat sleeve 10 is a pre-assembled seat cover, which is a shape coincided with the backrest portion 24 of the furniture frame 22, see image 3 with 4 The furniture frame 22 is a structural base for sofa, double sofa, chair or similar furniture item. The frame 22 of Fig. 1 has a webbing 25 that is pre-joined to the top crossbar 26 and the central crossbar (Breastrail) 28 before receiving a shape fit cover.

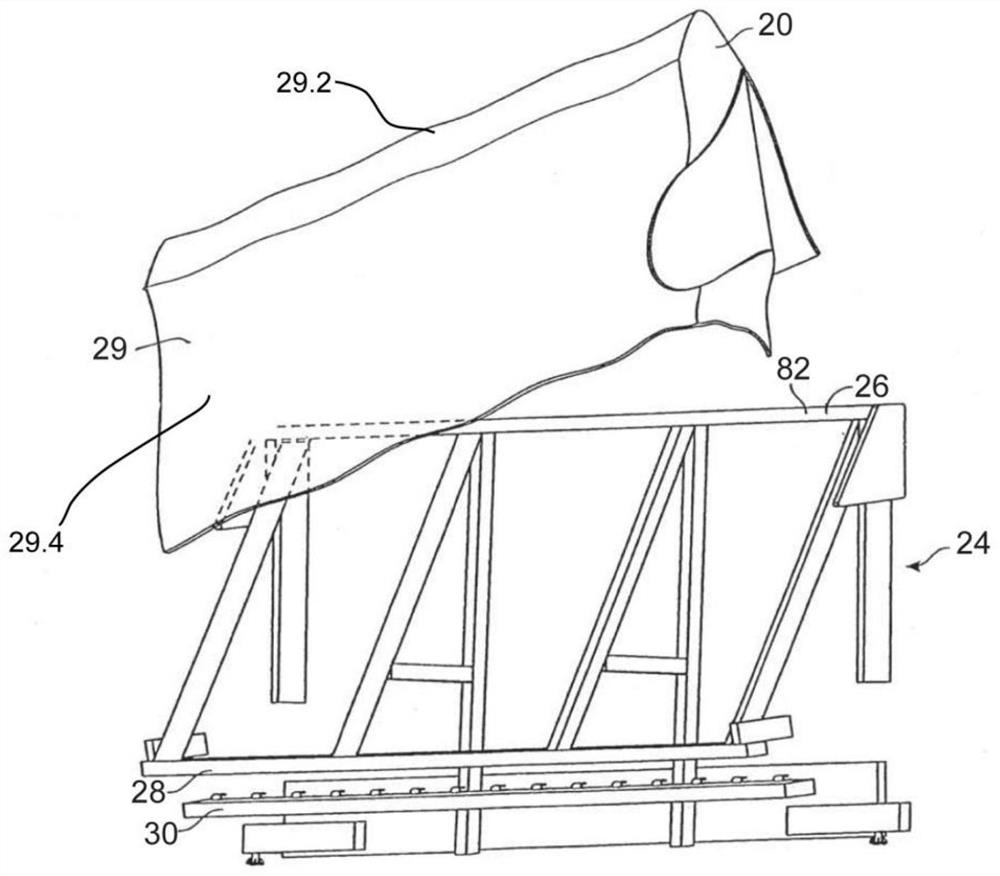

[0045] figure 2 The positioning of the seat sleeve 29 in the backrest portion 24 is illustrated such that the backrest portion 24 can be sufficiently inserted into the seat sleeve 29, so that the backrest portion 24 is packaged in the seat sleeve 29. The seat sleeve bag 29 is then coupled to the backrest portion 24 using a fastener such as a snail, as described below, the seat sleeve bag has a seat cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com