Forward sliding reclining chair

a reclining chair and forward sliding technology, applied in the direction of chairs, movable seats, transportation and packaging, etc., can solve the problems of limiting or eliminating the effectiveness of lumbar support, not providing adequate contours and/or bends to support users in the above described reclined body position, and common office chair recline mechanisms may not be fully accommodating for certain users.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

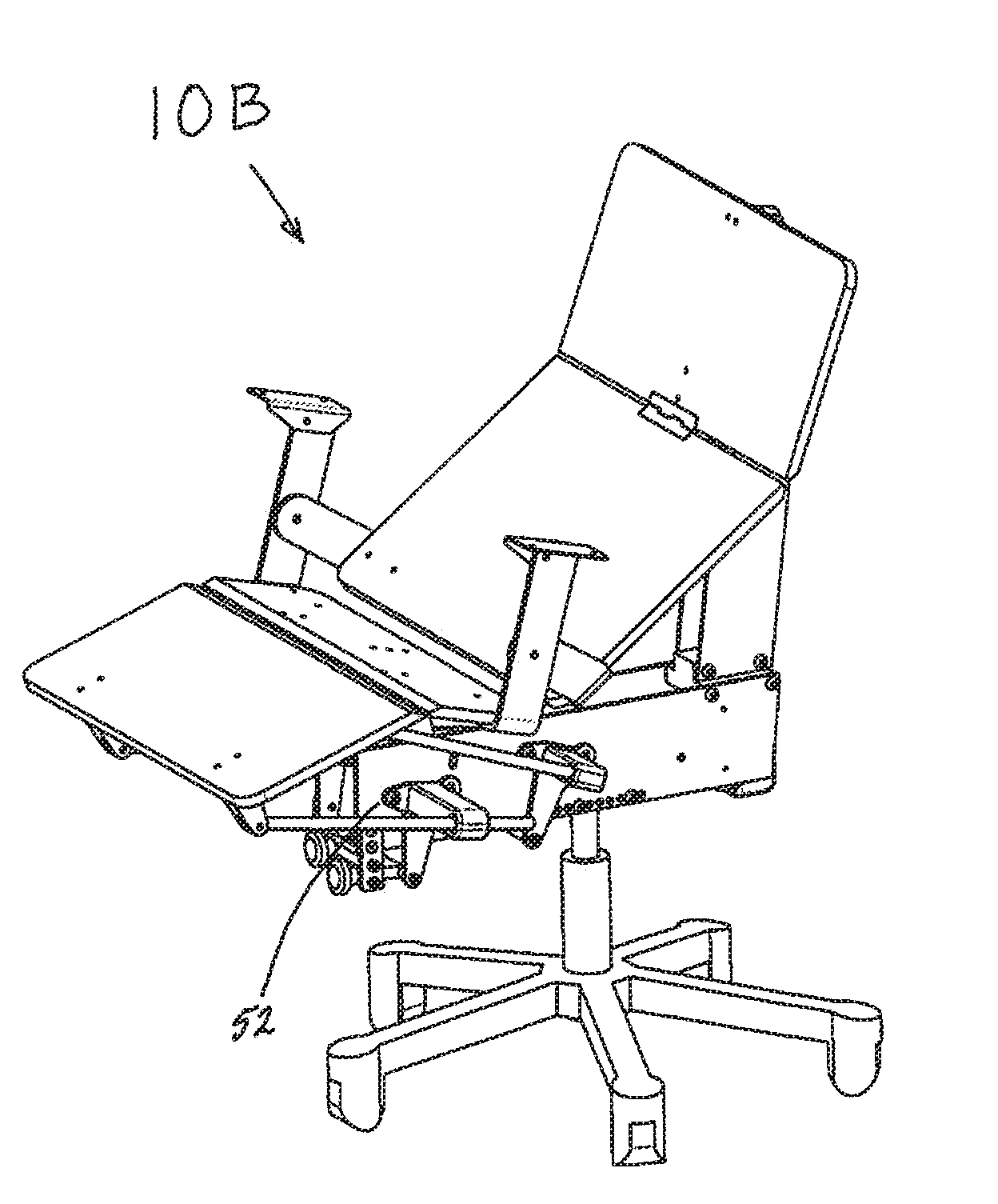

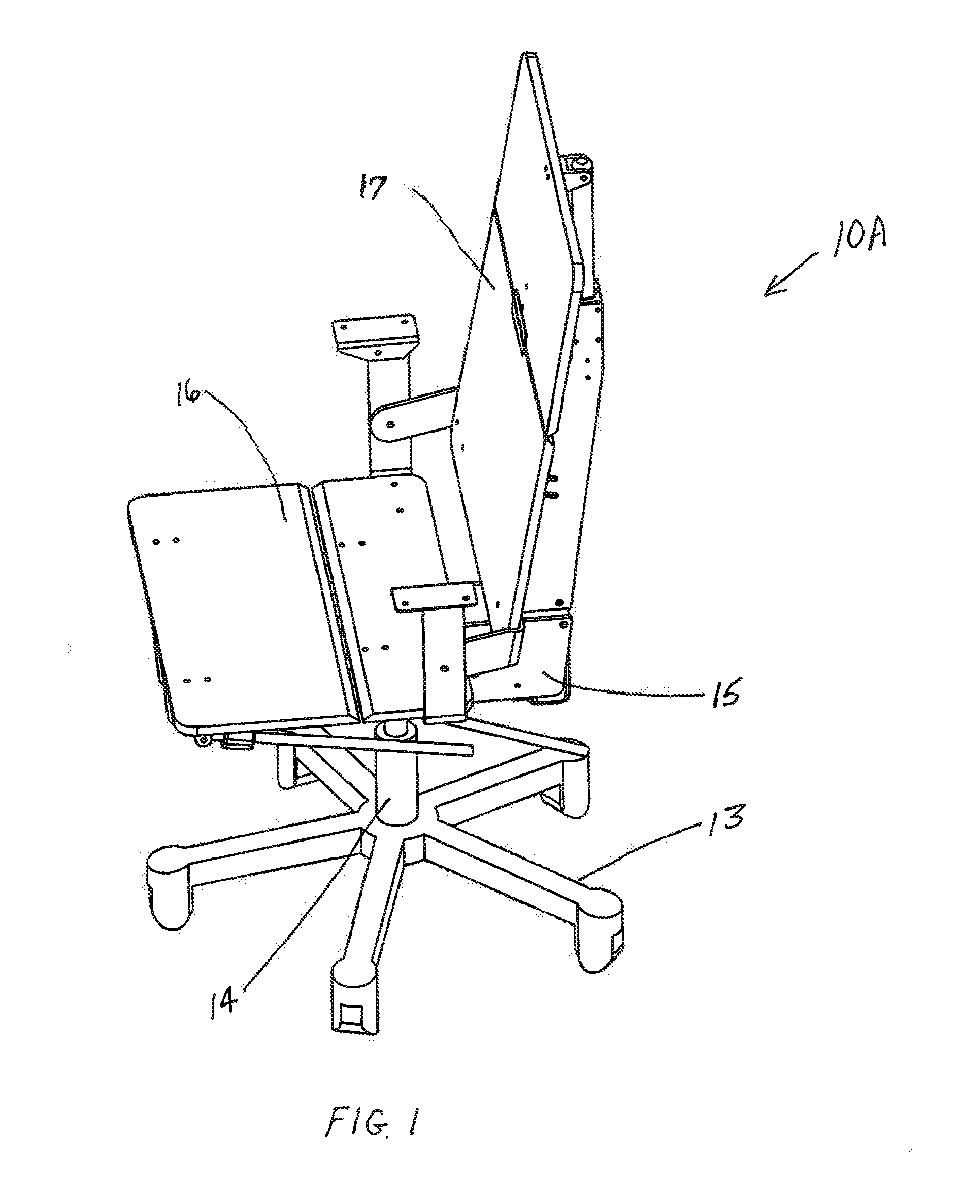

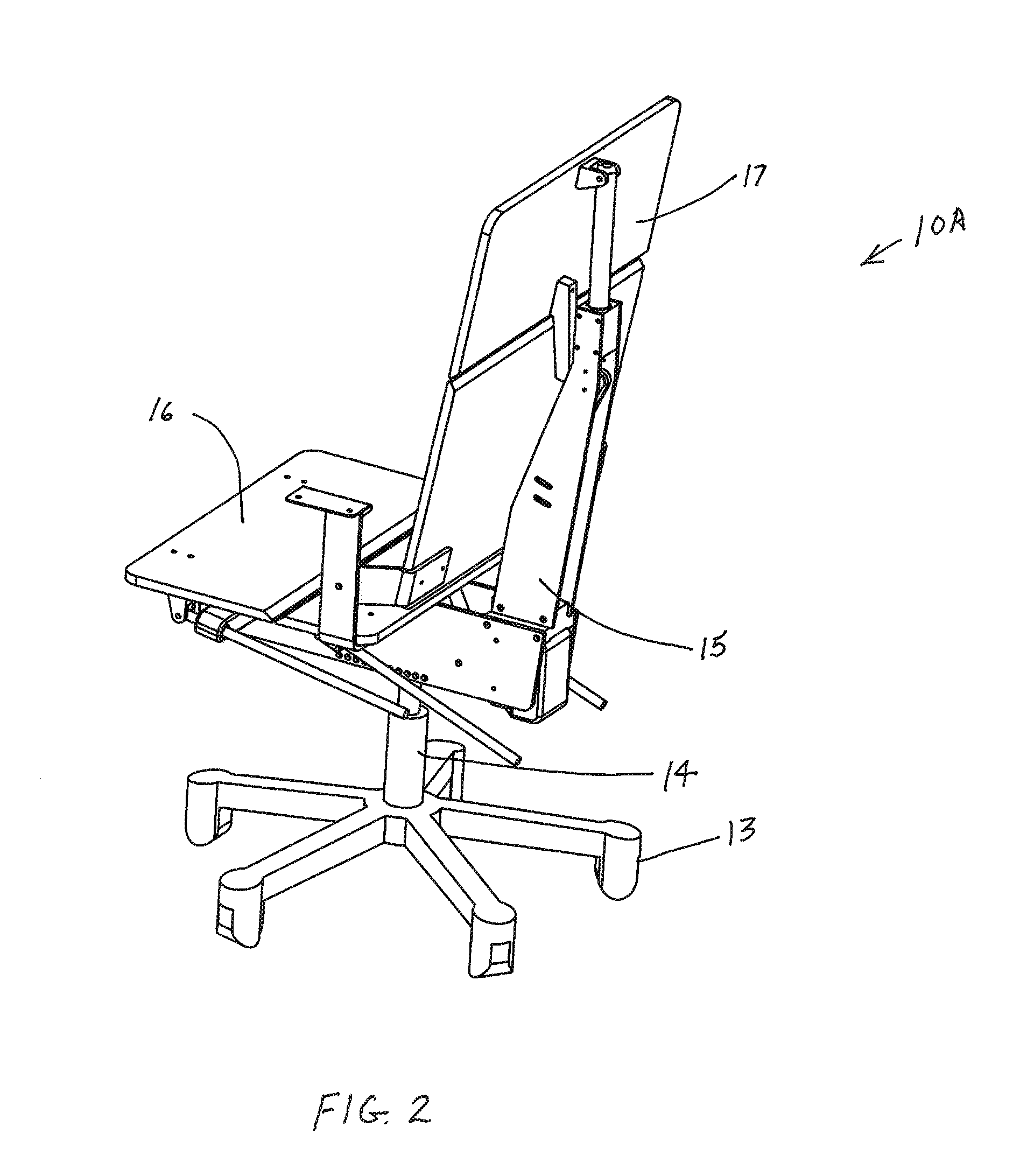

[0079]Referring to FIGS. 1-10, there is illustrated the forward sliding reclining swivel chair 10A (herein-after referred to as the “chair” for convenience) configured with a power driven recline mechanism.

[0080]The chair 10A includes a wheeled base assembly 13 having an upright support post 14 projecting therefrom. The upright support post 14 in turn mounts thereon a guide frame 15 which supports a slidable seat 16 which is pivoted to a reclinable back support 17, for supporting a seated user / occupant. The wheeled base assembly 13 includes a set of swiveling casters 38. Referring to FIG. 6, seat 16 has a front 18 and rear 19 portions that are pivotally connected by hinge 20. Back support 17 has upper 21 and lower 22 portions that are pivotally connected by hinge 23. The lower back support portion 22 is pivotally connected to seat rear portion 19 at pivot pins 24.

[0081]In one embodiment, the upper back portion 21 is pivotally connected near the top thereof to upper guide 25 by pin 2...

seventh embodiment

[0114]FIGS. 49-53 describe the forward sliding reclining swivel chair 10G. The basic structure and motions of chair 10G are nearly identical to chair 10F except that the motions are powered by an electric linear actuator 380 that replaces gas spring 280. Roller guide frame 335 includes all the components of roller guide frame 235 except bracket 275 and ball pivot 274 are replaced by bracket 375 and pivot pin 374. Seat rear portion 327 includes all the components of seat rear portion 227 except bracket 277 and ball pivot 276 are replaced by bracket 377 and pivot pin 376. Linear actuator 380 includes body portion 310 and drive rod 396. Body portion 310 includes motor 394 and screw housing 395. Linear actuator 380 is pivotally attached to bracket 377 at pivot pin 376 near the rearward end 397 of screw housing 395 thereof. Drive rod 396 is pivotally attached to bracket 375 at pivot pin 374 at the forward end thereof. The operation of linear actuator 380 is conventional in that, the shaf...

eighth embodiment

[0116]FIGS. 54-58 describe the forward sliding reclining swivel chair 10H. This embodiment is not motor driven. The recline motions are powered by gravity and the user / occupant while a gas compression spring 480 assists the user / occupant in the return stroke from reclined back to upright.

[0117]Chair 10H includes a wheeled base assembly 13 having an upright support post 14 projecting therefrom which includes a conventional height adjustable gas spring (not shown). Upright support post 14 in turn mounts thereon roller guide frame 435 which supports slidable seat assembly 470 which has pivotally connected thereto reclinable back support 471, for supporting a seated user / occupant.

[0118]The upper face of seat assembly 470 will normally be covered by a layer of foam cushioning and fabric, which is not shown. The wheeled base assembly 13 includes a set of swiveling casters 38. Seat 470 has front 425 and rear 427 portions that are pivotally connected by hinge 426.

[0119]Back support 471 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com