Rotation and lifting transmission mechanism of hosiery machine

A lifting drive mechanism and lifting transmission technology, which is applied in the field of hosiery machine rotation lifting transmission mechanism, can solve problems such as unstable work, inability to accurately locate the height of the gripping parts of socks, unstable lifting of the gripping parts, etc., and achieve the goal of solving the lifting accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

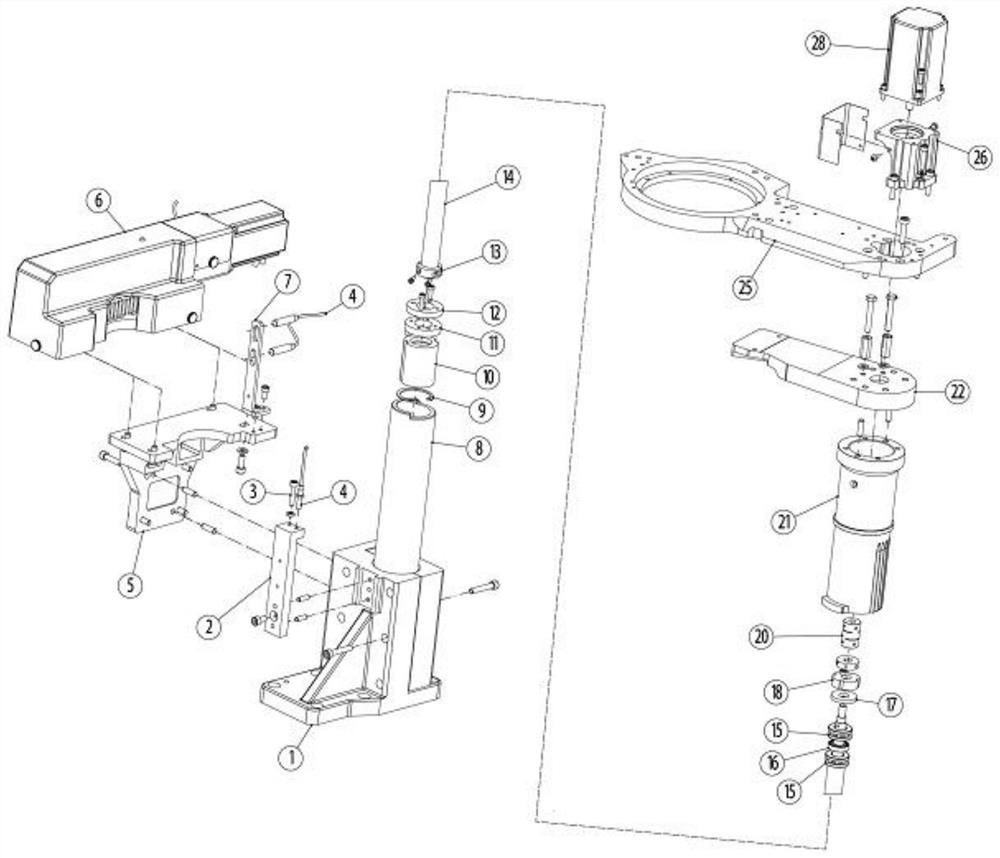

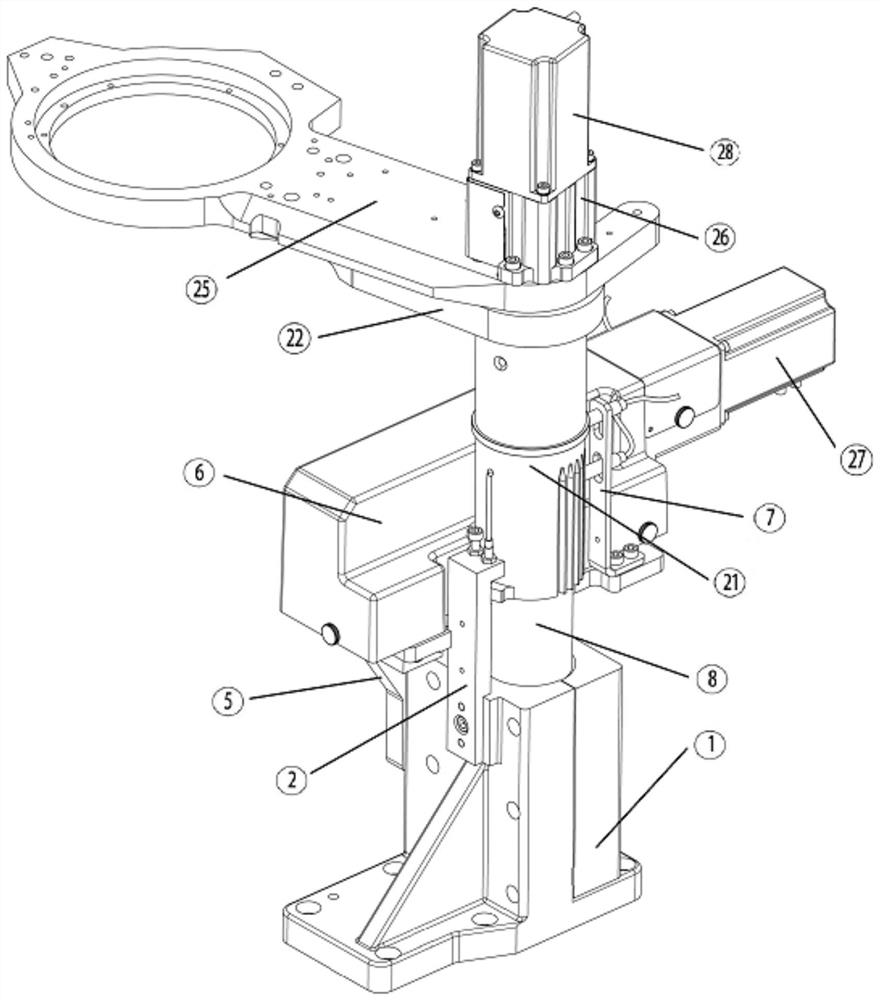

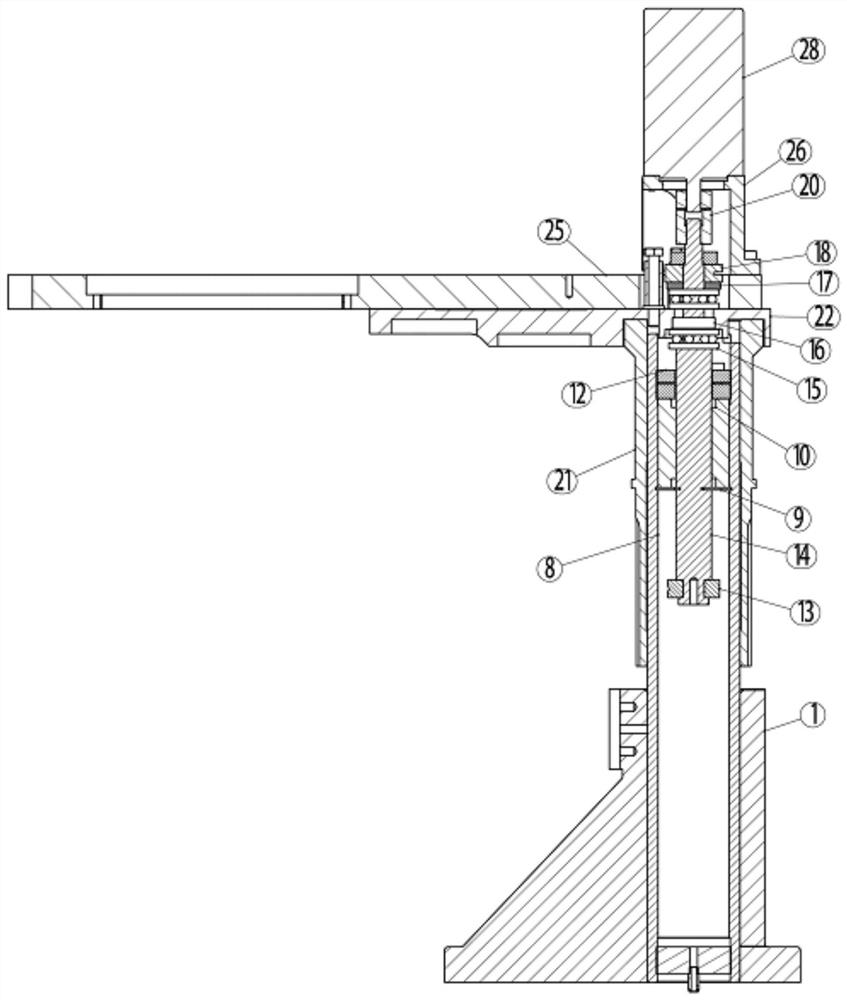

[0028] Refer Figures 1 to 7 DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS

[0029] A sock machine rotation lifting drive mechanism, reference figure 1 with figure 2 The structure is shown, including a base 1, and a guide shaft 8 is mounted on the base 1, and the guide shaft 8 is provided with a transfer gear 21, and the upper end of the transfer tooth 21 is connected to a swing arm 25, said A transfer mechanism 6 that drives the transfer gear 21 rotation is provided on one side of the pedestal 1, which is provided with a lifting drive mechanism that controls the transfer gear 21 lifting down, and is disposed on the base 1 There is a sensing device 4 that feeds back the transfer tooth 21.

[0030] The swaying arm 25 is provided with a sock, and the transfer gear 21 can move up and down in the guide shaft 8 under the action of the lifting drive mechanism, the transfer mechanism 6 on the side controls the transfer tooth 21 rotation, transfer the cos 21 and the swing arm 25. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com