Vehicle-mounted air compression device based on vibration driving

An air compression and vibration-driven technology, applied in the field of compression devices, can solve the problems of reduced driving mileage and failure to find the driving source, etc., and achieves the effects of high reliability, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

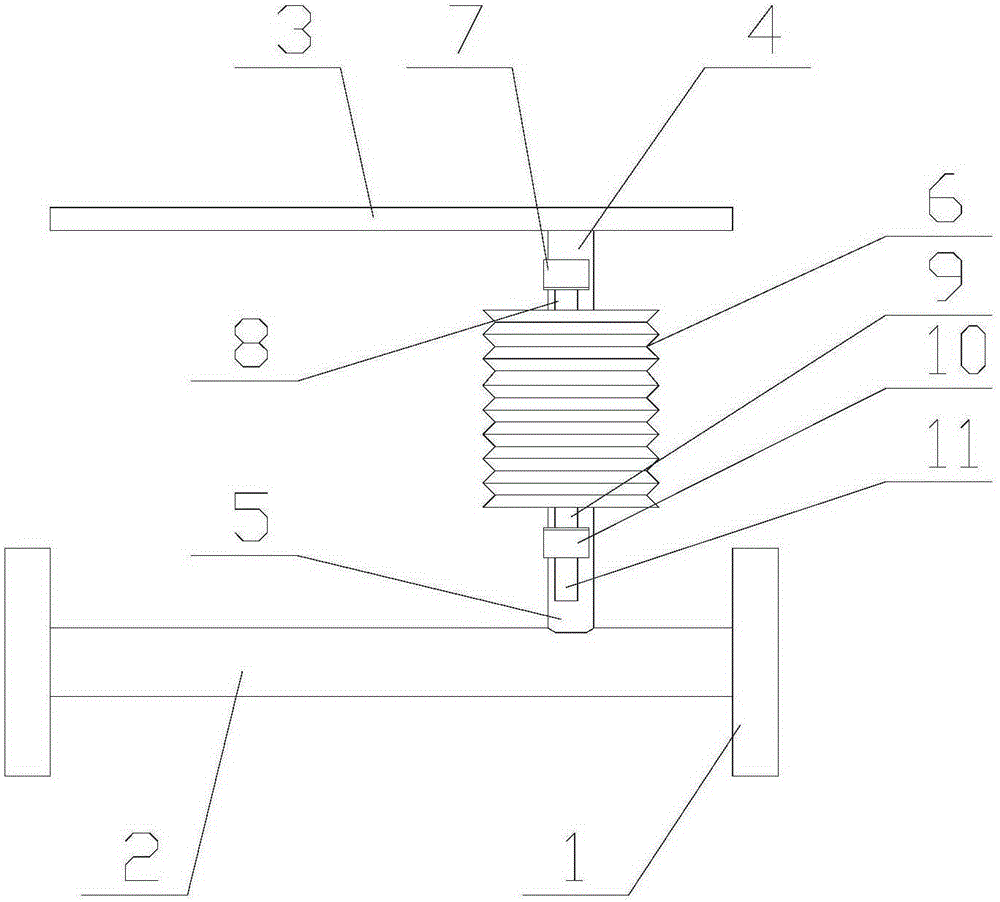

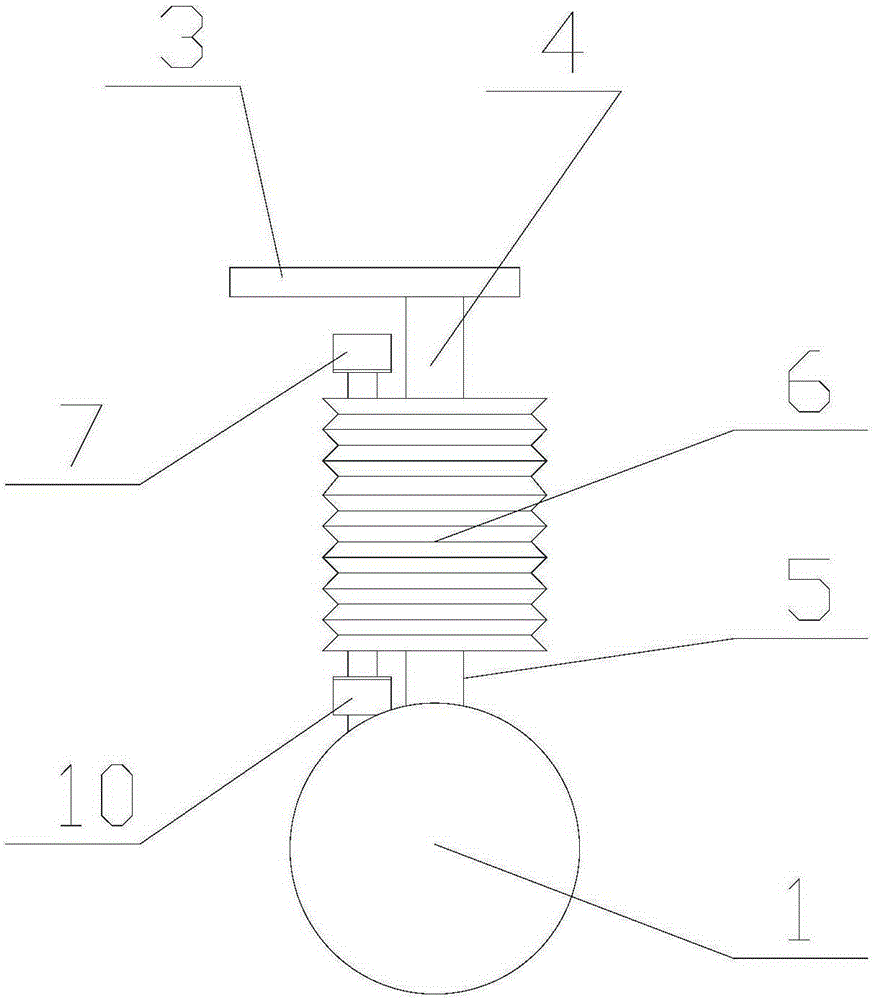

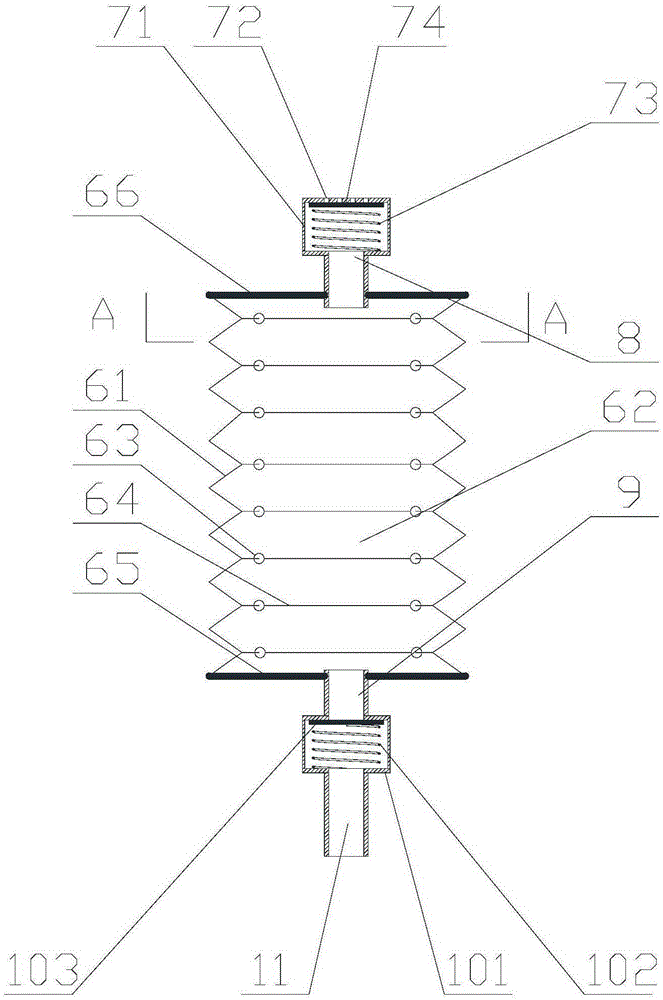

[0018] see Figure 1-Figure 5 , is the front view and corresponding auxiliary view of a vehicle-mounted air compression device based on vibration drive in the present invention. A kind of vibration-driven vehicle-mounted air compression device of the present invention comprises: an upper connecting rod 4 connected and fixed with the vehicle frame 3, and a lower connecting rod 5 connected and fixed with the axle 2 (the two ends of the axle 2 are connected with the wheels 1); A compression device 6 is provided between the upper connecting rod 4 and the lower connecting rod 5, and the compression device 6 includes: a folding plate 61, an upper base plate 66, a lower base plate 65, and a compression chamber 62 formed by the above three, the compression chamber 62 is provided with an anti-stretch ring 64 inside, and the surroundings of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com