Energy dissipation device made of metal tube

A technology of energy dissipation device and metal pipe, applied in construction, protective equipment, etc., can solve problems such as stuck wire rope, wire rope wear, wire rope breakage, etc., and achieve the effect of solving complex mechanical mechanism, thorough deformation, and avoiding friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

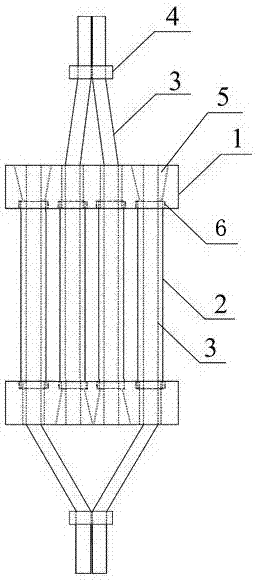

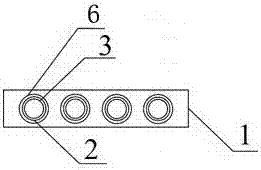

[0023] Such as figure 1 and figure 2 As shown, this embodiment includes a fixing part 1, a metal pipe 2, a steel wire rope 3, a wire clip 4 and a clip 5. The fixing part 1 is a rectangular metal block with two sets of symmetrical countersunk through holes 6. The two fixing parts 1 Relatively insert the metal pipe 2 in the countersunk groove, and the countersunk groove of the countersunk through hole 6 is used to restrain the end of the metal pipe 2;

[0024] The steel wire rope 3 enters through the countersunk through hole 6 of a fixing piece, passes through the metal pipe 2, and one end of the steel wire rope 3 is anchored in the through hole of the countersunk through hole 6 of the other fixing piece 5 through the clip 5; from one of the fixing pieces 1 A set of symmetrical countersunk through-holes 6 lead out steel wire ropes 3 , and a group of steel wire ropes 3 drawn out from the outside of the fixing part 1 are merged and connected together by wire clips 4 .

[0025] ...

Embodiment 2

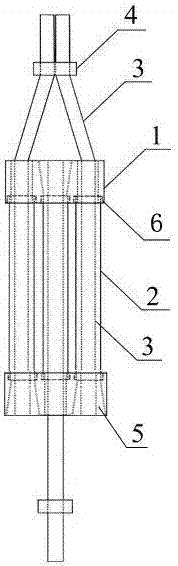

[0027] Such as image 3 and Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the fixing member 1 is a circular metal block with two sets of symmetrical countersunk through holes, and the symmetrical countersunk through holes are evenly distributed on the circumference.

[0028] It is not difficult to imagine that the fixing member 1 can also be a square metal block with two sets of symmetrical countersunk through holes, and the symmetrical countersunk through holes are evenly distributed on the diagonal.

[0029] In the above embodiment, there are only two symmetrical countersunk holes. Of course, the number of countersunk holes may be three or more to form a symmetrical group of symmetrical countersunk holes.

[0030] The fixing part 1 mainly plays the role of fixing and positioning. There are symmetrical metal pipes between the fixing parts. The fixing part 1 has two sets of symmetrical countersunk through holes 6. The through holes of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com