Profile assembling structure for composite air pipe connecting flange

A technology for composite air ducts and connecting pipe flanges, which is applied in the direction of pipes/pipe joints/fittings, connecting components, flange connections, etc., can solve the problems of poor support and reinforcement of composite air ducts, and achieve efficient and convenient assembly and reliable connection strength , Improve the effect of assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

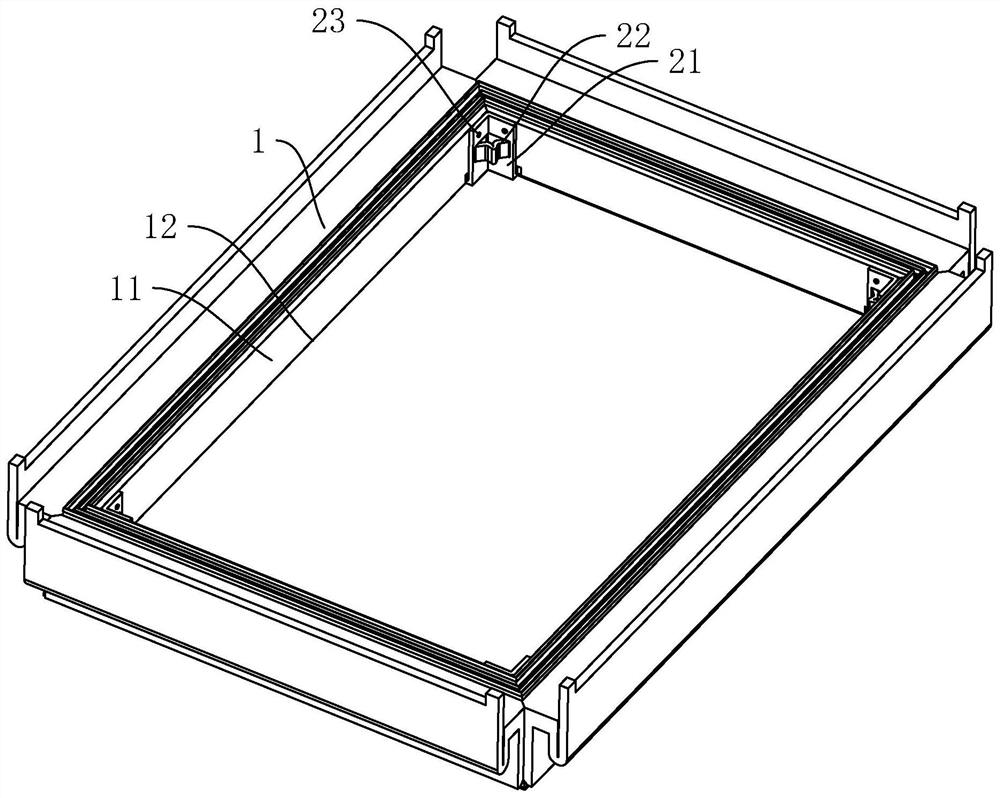

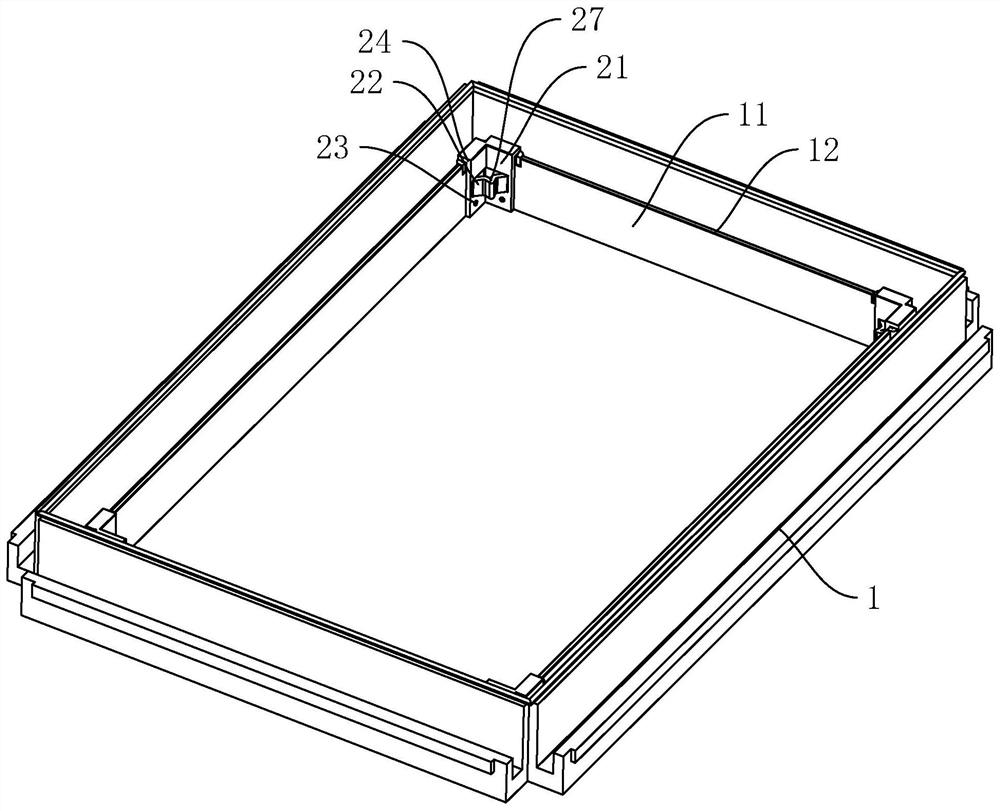

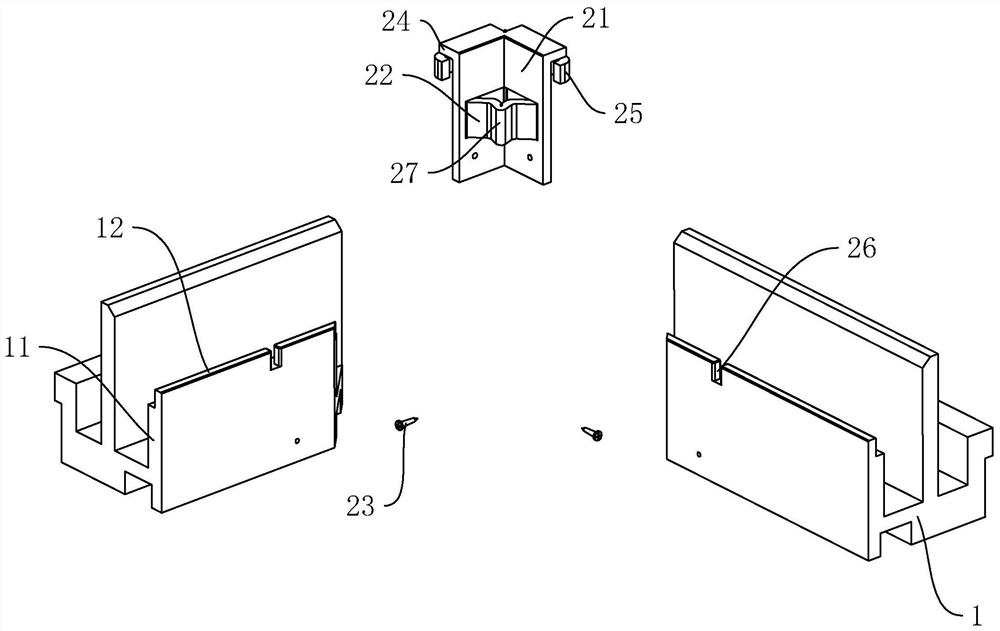

[0030] Profile assembly structure for composite air duct flanges, such as figure 1 , figure 2 , image 3 As shown, it includes four profiles 1 connected end to end to form a rectangular frame structure. A connection structure is provided between the included corners of adjacent profiles 1. The connection structure includes a fitting part 21 and a diagonal support part 22. The end surface of the fitting part 21 is It is a right-angle structure when viewed from the front, and is embedded in the inner angle of the adjacent profile 1. The two sections of the fitting part 21 are respectively attached to the inner wall of the adjacent profile 1, and are fixed with self-tapping screws 23. The diagonal support part 22 It is arranged in the middle of the bonding portion 21 in the longitudinal direction, and supports the two sections of the bonding portion 21 in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com