Clamping and connection structure of automobile door footboard and automobile body plate

A technology of automobile door and connection structure, which is applied in the direction of thin plate connection, upper structure, connection components, etc., can solve the problems of labor and time-consuming maintenance, and achieve the effect of ensuring the clamping strength, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

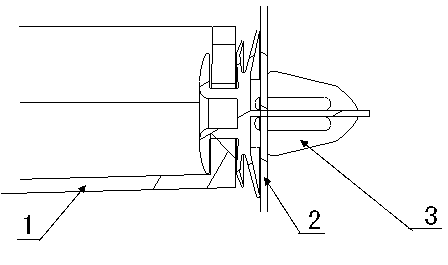

[0009] Depend on figure 1 Known, a car door step and the body plate clamping structure, by the car door step 1, the body sheet metal 2 and the plastic buckle 3, the plastic buckle 3 is first inserted into the assembly hole of the car door step 1, and the car door step is connected with the car door step. After the 1 is connected as a whole, the plastic buckle 3 is pressed into the assembly hole of the body sheet metal 2, and the connection between the pedal body 1 and the body sheet metal 2 is realized through the plastic buckle 3.

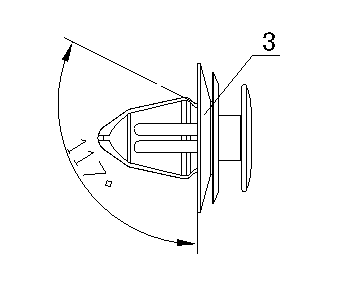

[0010] Depend on figure 2 Know, is a schematic diagram of the plastic buckle. The clip angle of the plastic clip 3 is 117o.

[0011] Working principle: The plastic buckle 3 is directly inserted into the assembly hole of the step body 1, and then the plastic buckle 3 is pressed into the assembly hole of the body sheet metal 1. For connection, the angle of the plastic clip is 117o, which can be easily disassembled while ensuring the strength of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com