Rapid positioning and connecting structure for metal filter bag flange and tubesheet

A metal filter bag and connection structure technology, which is applied in the field of rapid positioning connection structure between metal filter bag flanges and flower plates, can solve problems such as affecting process and production, wasting manpower and financial resources, reducing installation efficiency, etc. Improve installation efficiency and overall practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

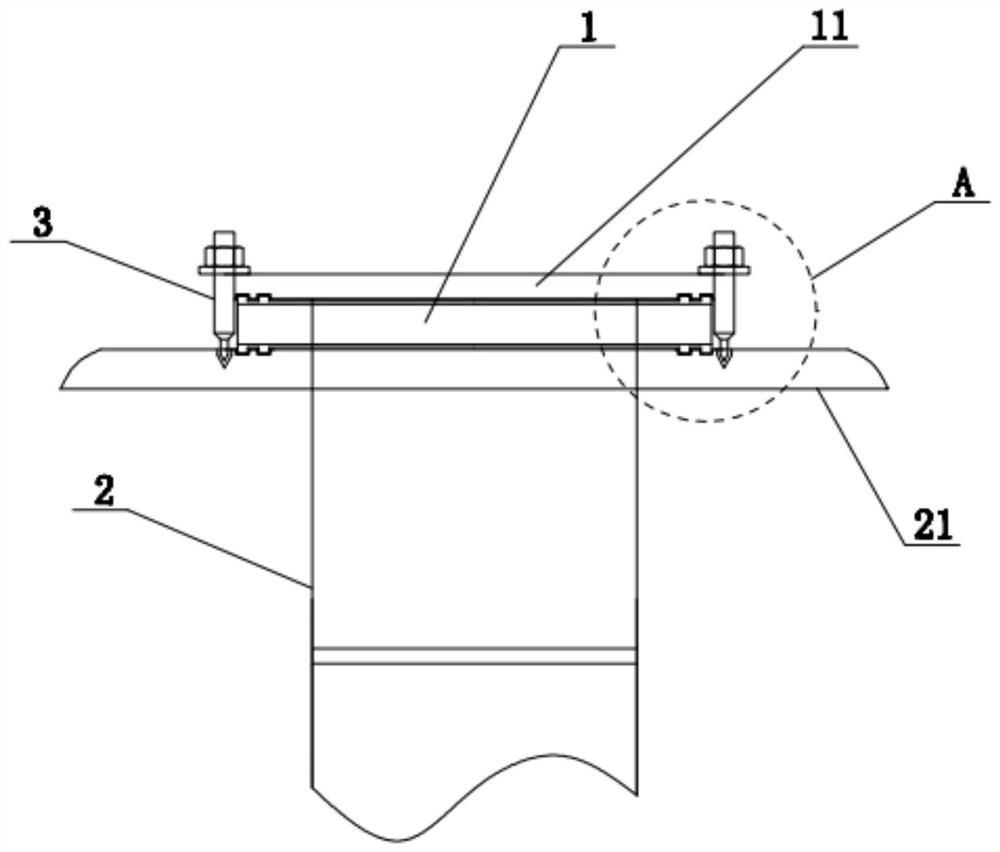

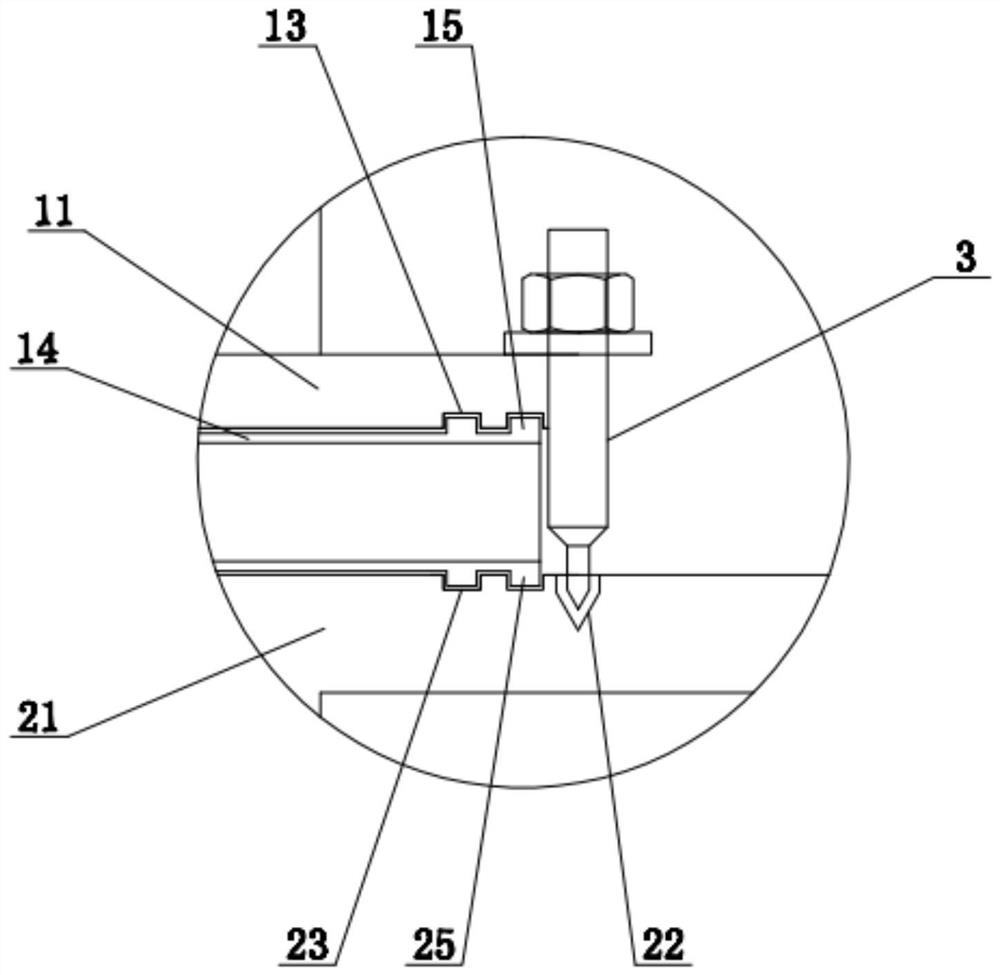

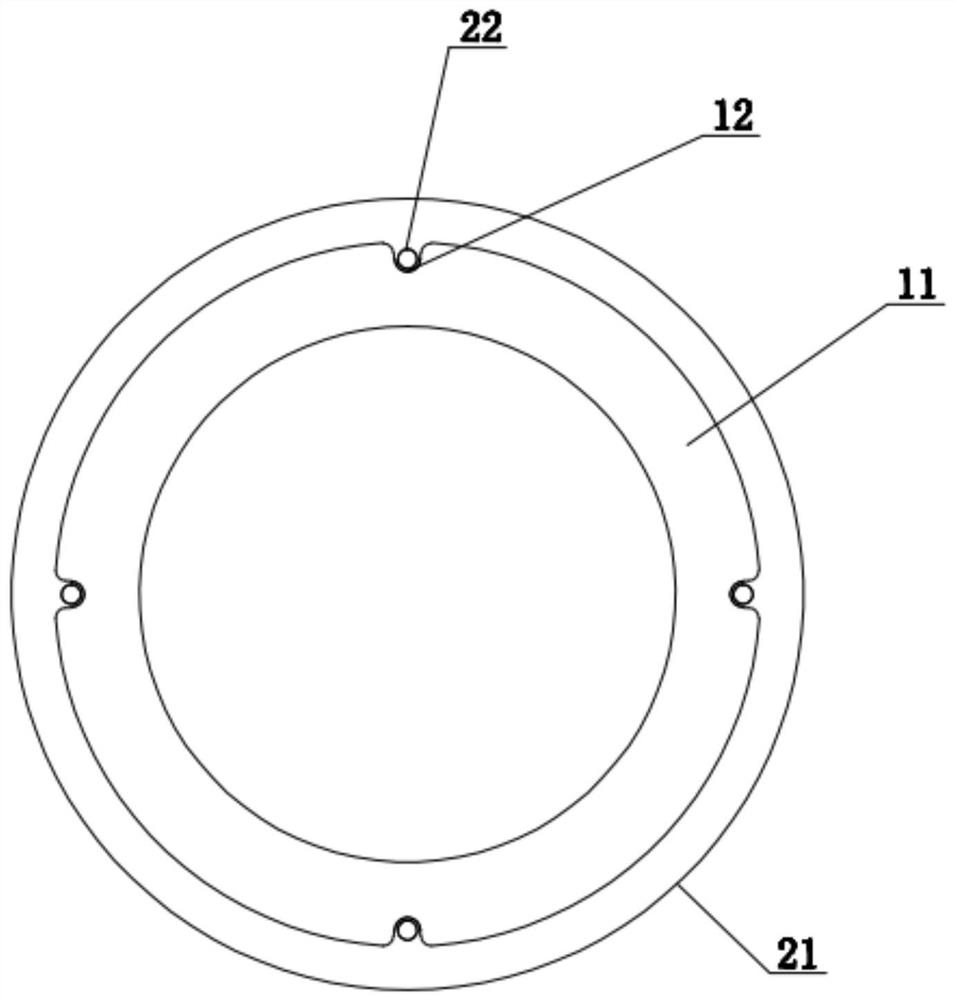

[0017] see Figure 1 to Figure 4 As shown, the technical solution adopted in this specific embodiment is: it includes a ceramic sealing ring 1, a metal filter bag 2, and a flower plate 21, the metal filter bag 2 passes through the middle of the flower plate 21, and the end of the metal filter bag 2 is provided with The connecting flange 11 is provided with a ceramic sealing ring 1 between the connecting flange 11 and the flower plate 21, and the outer circumference of the connecting flange 11 is provided with four butt arc grooves 12 at equal angles, and the outer circumference of the flower plate 21 is provided with four A circular groove 22, the connecting flange 11 and the flower plate 21 are connected correspondingly through the docking arc groove 12 and the circular groove 22, and the butt arc groove 12 and the circular groove 22 are connected by a quick positioning bolt 3 Rapid positioning, compression sealing and fixed connection through spot welding process, changed th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com