Container with removable base assembly

A container and base technology, which is applied in the container field of base components, can solve the problems of inability to clean the container, fall off of the protective pad, inconvenience for users, etc., and achieve the effect of thorough cleaning and elimination of toxic substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

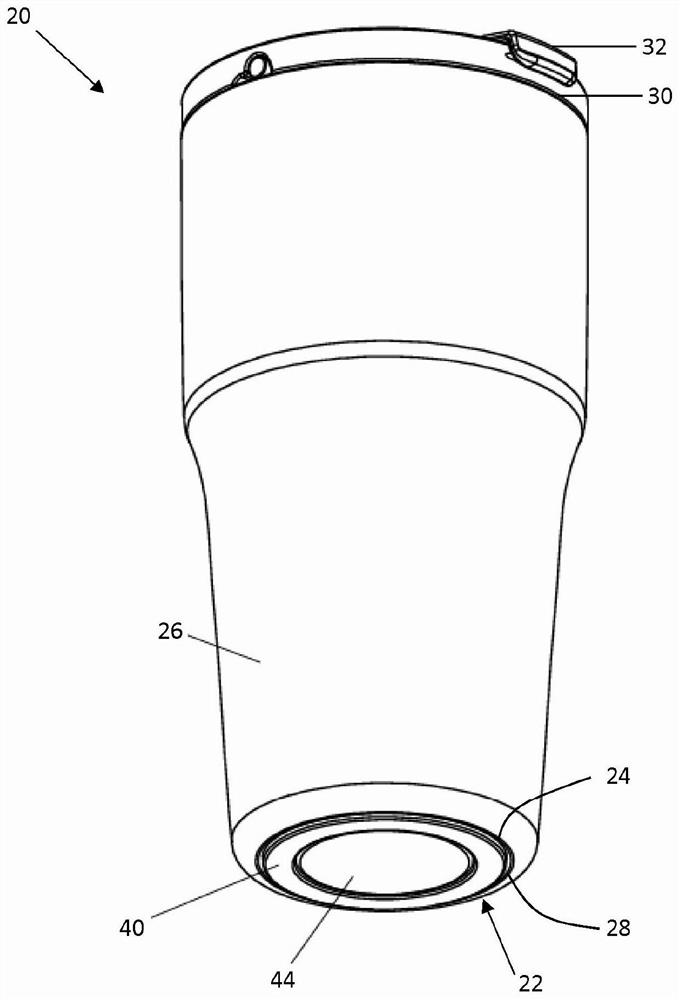

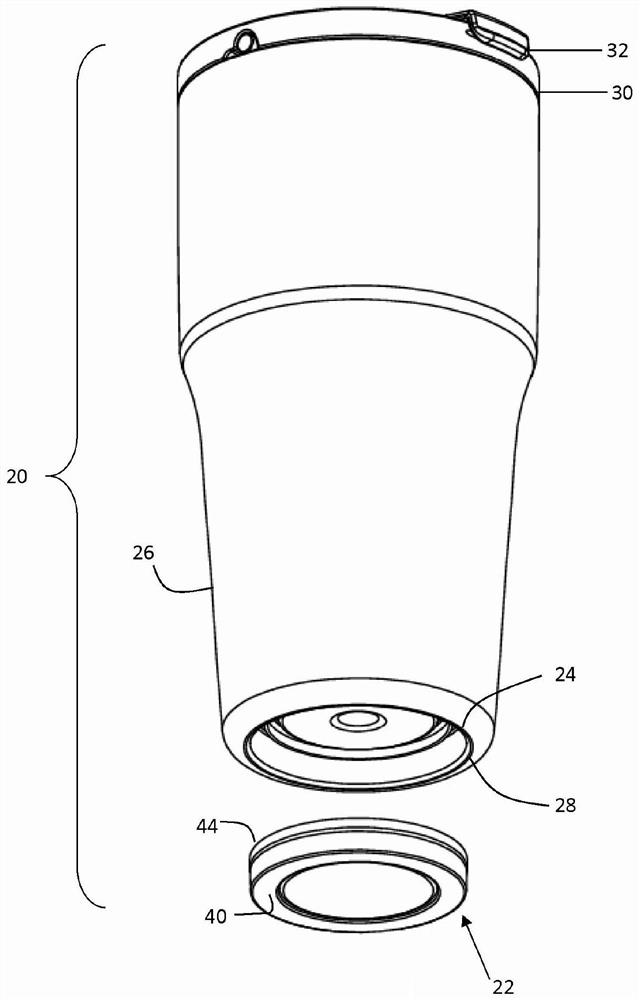

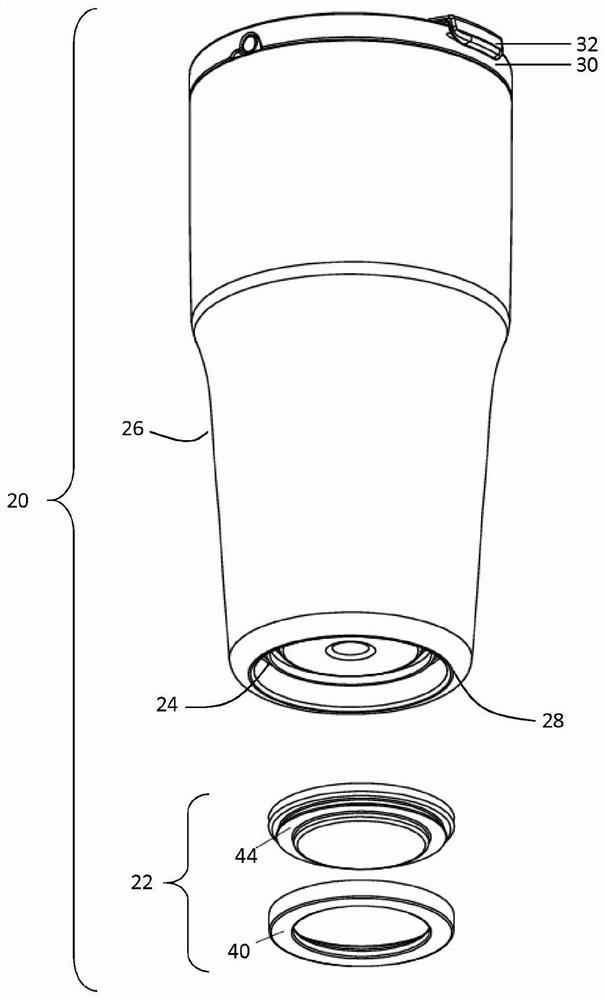

[0038] figure 1 An exemplary container 20 is shown with a base assembly 22 inserted into a recess 24 of the container. The container 20 may be a beverage container, or another personal use container for containing fluids or solids, where it is desirable to provide vibration isolation and non-slip protection on the surface of the container placed in contact with the support surface on which the container rests. Cushion pads made of type material. In the exemplary container shown in the figures, container 20 has side walls 26 that define the volume of the container and a bottom 28 that extends below the side walls when the container is upright. The container may be provided with a curved transition from the side wall 26 to the bottom 28 . A recess 24 that receives the base assembly 22 may be formed in the bottom 28 . The depicted container also has a top 30 opposite the bottom, and the top has an opening to the interior of the container, eg for containing a user's drink. Con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com