Bolt tension value calculation ruler mechanism and use method thereof

A technology of slide rule and tension value, which is applied to measure the direction of torque/torsion force during tightening, which can solve the problems of inconvenient observation, inconvenient dynamic adjustment of relevant parameters, inconvenient reverse calculation of preload force and stiffness value, etc. The effect of strong performance, reasonable design and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

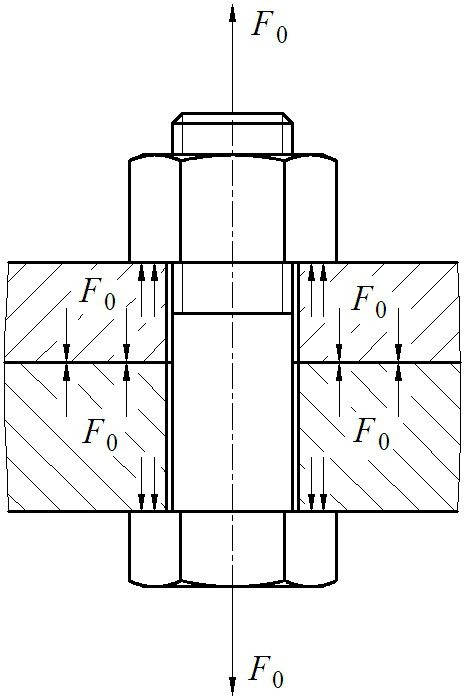

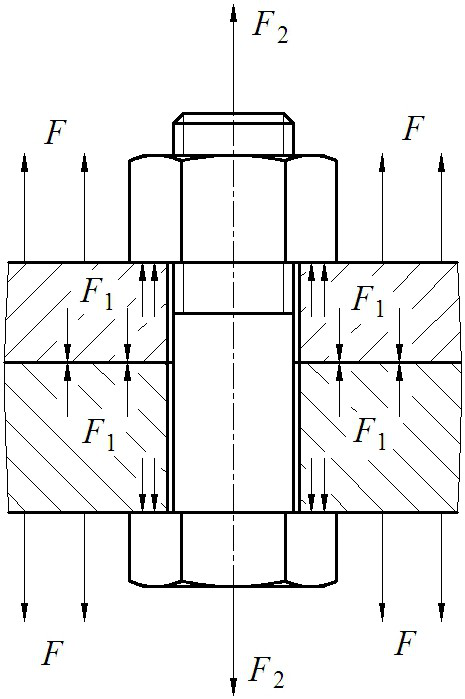

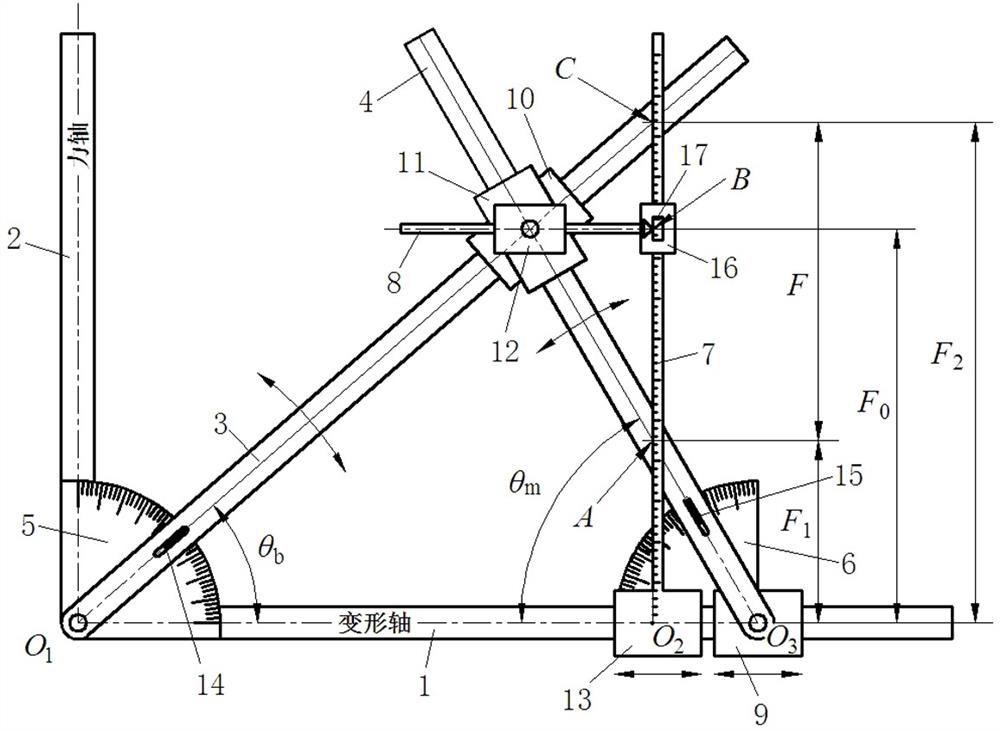

[0037] Known: bolt stiffness C b , Stiffness of connected parts C m , preload F 0 , working tension F . Find: The maximum tension of the bolt F 2 and residual preload F 1 ;

[0038] The method of use includes the following steps:

[0039] 1) According to the bolt stiffness C b and the stiffness of the connected parts C m According to the scale on the bolt stiffness dial 5 and the stiffness dial 6 of the connected part, adjust the angle between the bolt stiffness rod 3 and the deformation axis 1 θ b , and the angle between the stiffness rod 4 of the connected part and the deformation axis 1 θ m ;

[0040] 2) According to the preload F 0 size, at the angle of rod 4 maintaining the stiffness of the connected parts θ m Under the same situation, adjust the position of the pretightening force adjustment slide block 9 left and right, so that O 2 B = F 0 ;

[0041] 3) According to the working tension F size, adjust the left and right positions of the fo...

Embodiment 2

[0044] Known: bolt stiffness C b , Stiffness of connected parts C m , residual preload F 1 , working tension F . Ask for: preload F 0 size;

[0045] The method of use includes the following steps:

[0046] 1) According to the bolt stiffness C b and the stiffness of the connected parts C m According to the scale on the bolt stiffness dial 5 and the stiffness dial 6 of the connected part, adjust the angle between the bolt stiffness rod 3 and the deformation axis θ b , and the angle between the stiffness rod 4 of the connected part and the deformation axis θ m ;

[0047] 2) According to the residual preload F 1 and working pull F value, adjust the position of the force value scale left and right;

[0048] 3) According to the residual preload F 1 value, adjust the position of the preload adjustment slider 9, so that O 2 A = F 1 ;

[0049] 4) Reading: bolt pre-tightening force F 0 = O 2 B .

[0050] It should be noted that the present invention...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap