Wave glider armored cable performance test platform

A test platform, armored cable technology, applied in the direction of using stable torsion to test the strength of materials, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problem of incomplete fatigue life test function and discontinuous data detection. , single test mode and other problems, to achieve the effect of expanding the fatigue life test function, realizing continuous measurement and reducing manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 The application is described in further detail.

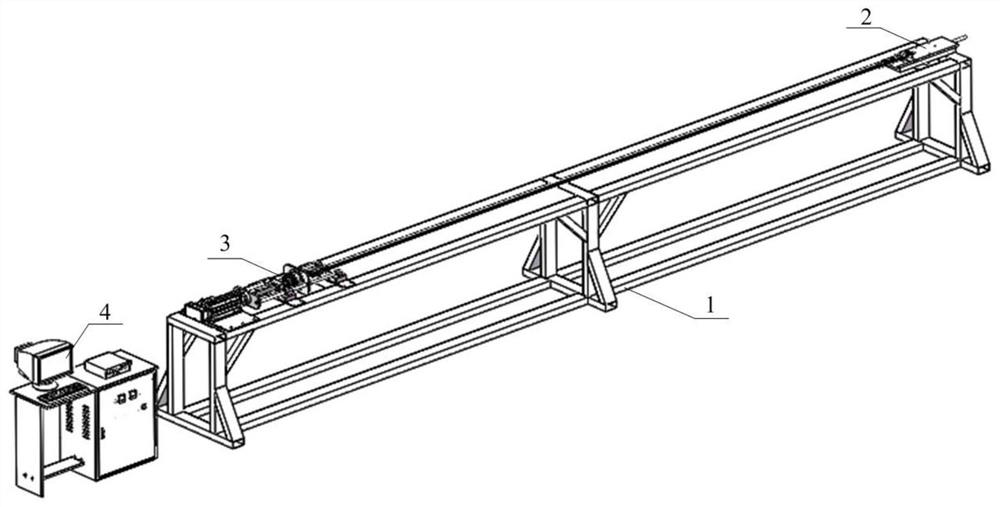

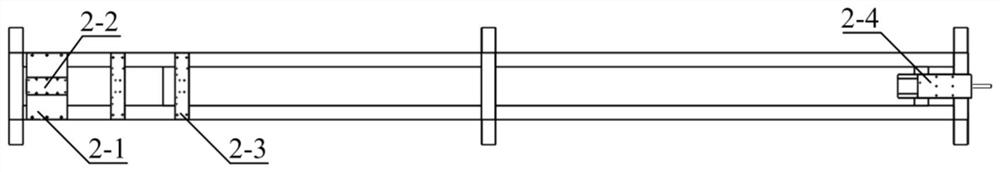

[0021] The embodiment of the present application discloses a performance testing platform for an armored cable of a wave glider. refer to figure 1 A wave glider armored cable performance testing platform includes four parts: a load-bearing support 1, a fixed adjustment system 2, a stretching torsion system 3, and a semi-automatic digital display system 4. The load-bearing support 1 is divided into upper and lower layers, placed on the ground, the fixed adjustment system 2 is installed on the upper surface of the load-bearing support, the tension torsion system 3 is installed on the fixed adjustment system 2, and the semi-automatic digital display system 4 is placed on the bearing. Power bracket aside.

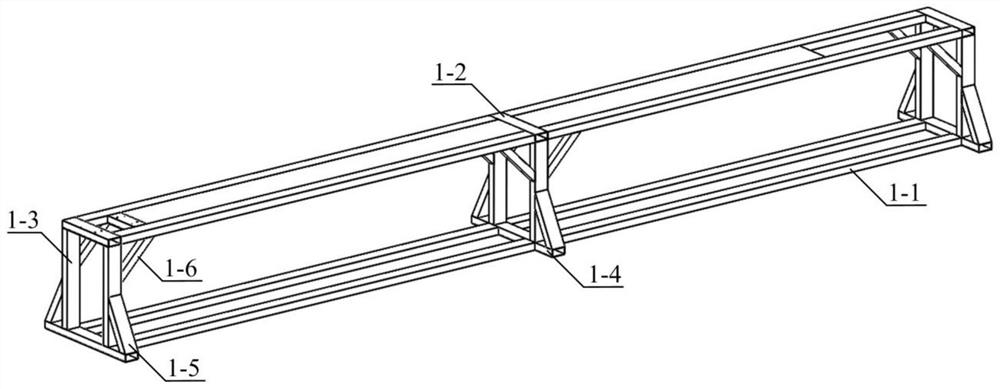

[0022] The load-bearing support 1 is divided into upper and lower layers. The upper layer is welded into a rectangular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com