Grid patch retrieval method for curved surface part measurement points based on vector cross multiplication

A technology of curved surface parts and measurement points, which is applied in the precision field of curved surface parts, can solve the problems of lack of direct methods for the retrieval operation of mesh patches corresponding to measurement points, and achieve the effect of occupying less computer resources and less time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

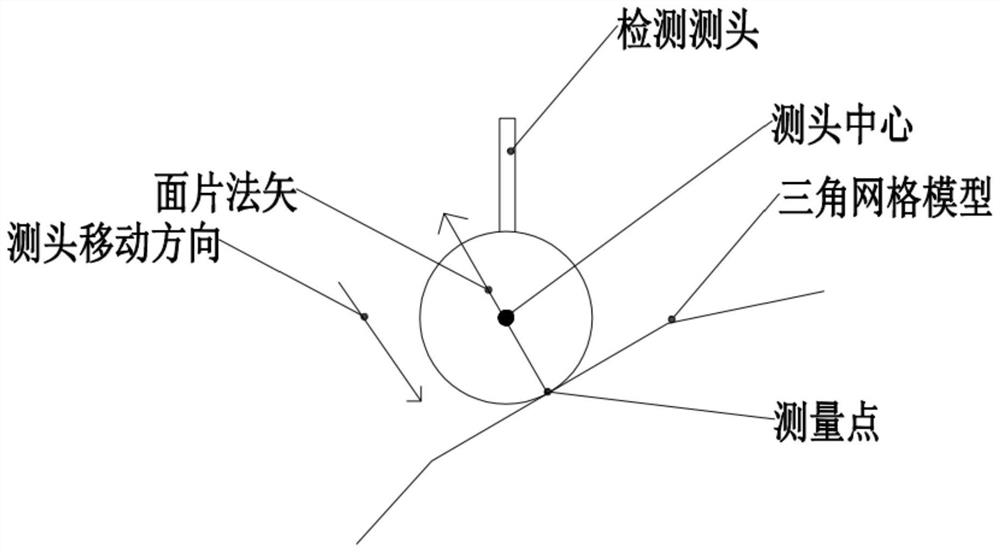

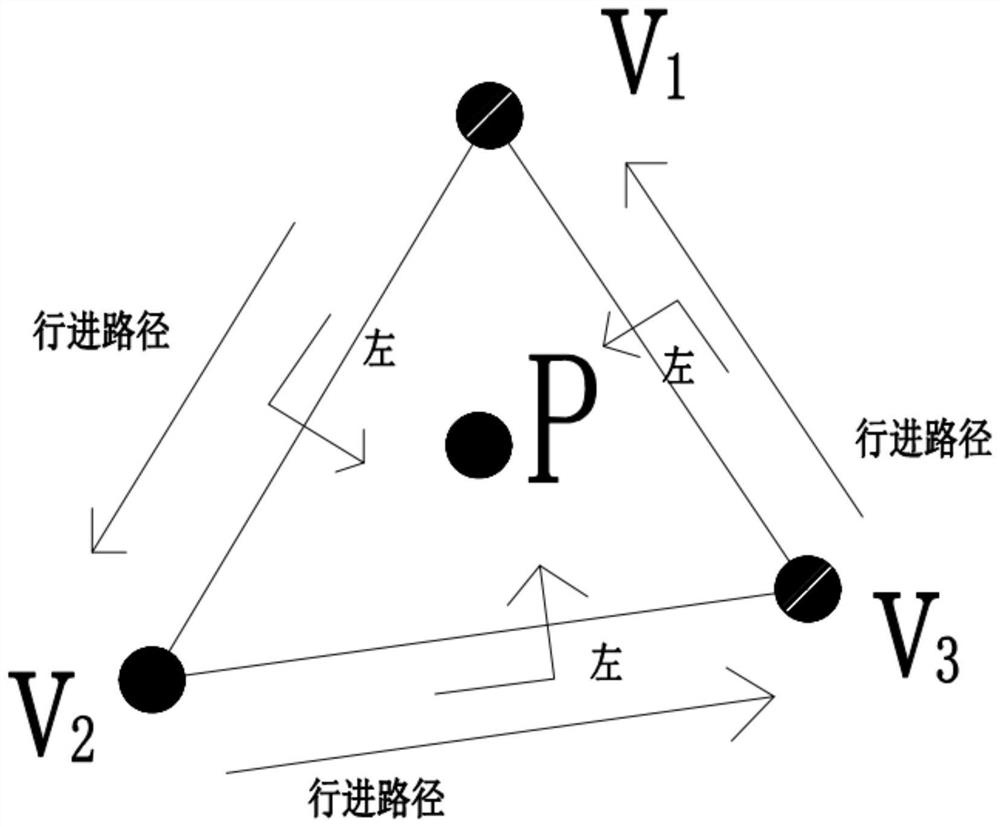

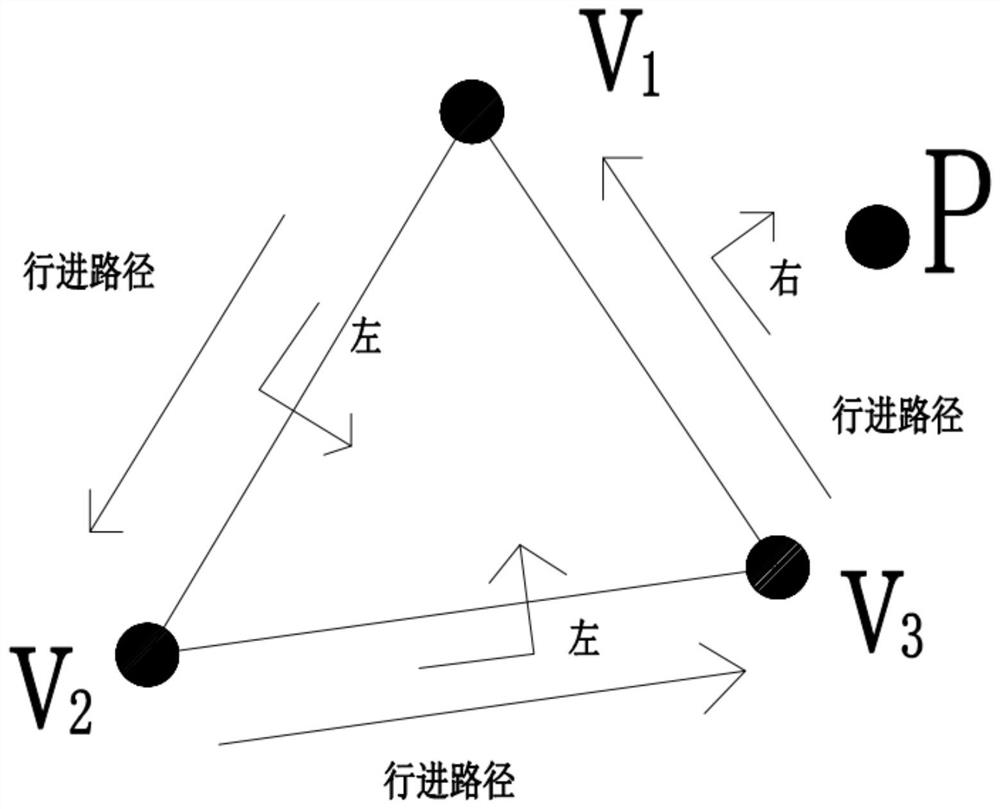

[0092] In the prior art, the triangular mesh model is used to express the outline of complex curved surface parts, but the angular mesh model is composed of a series of connected triangular faces to approximately express the outline of the model, in the computer in the STL file format For storage, the data information of each grid surface is listed one by one in the file. However, the storage order of the mesh patches is random, and each mesh patch only records the normal vector of the mesh patch and the coordinate information of the three vertices.

[0093] The data information of each mesh patch in the STL file consists of 7 lines of code, as shown in the following example:

[0094]

[0095] Among them, the first line is the normal vector direction data pointing to the outside of the entity; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com