Battery leakage detecting and weighing equipment

A battery and weighing technology, which is applied in the direction of weighing, measuring devices, instruments, etc., can solve the problems of battery leakage, insufficient welding, and the accuracy of the amount that greatly affects the performance of the battery, so as to achieve high production efficiency and overall structure Compact and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

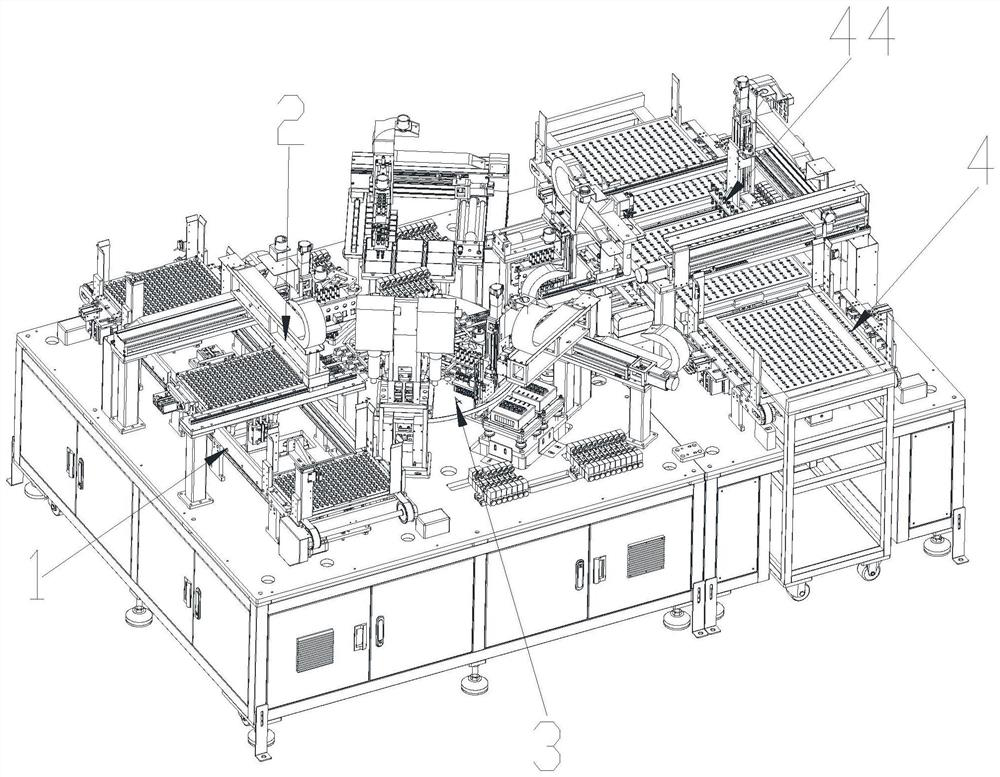

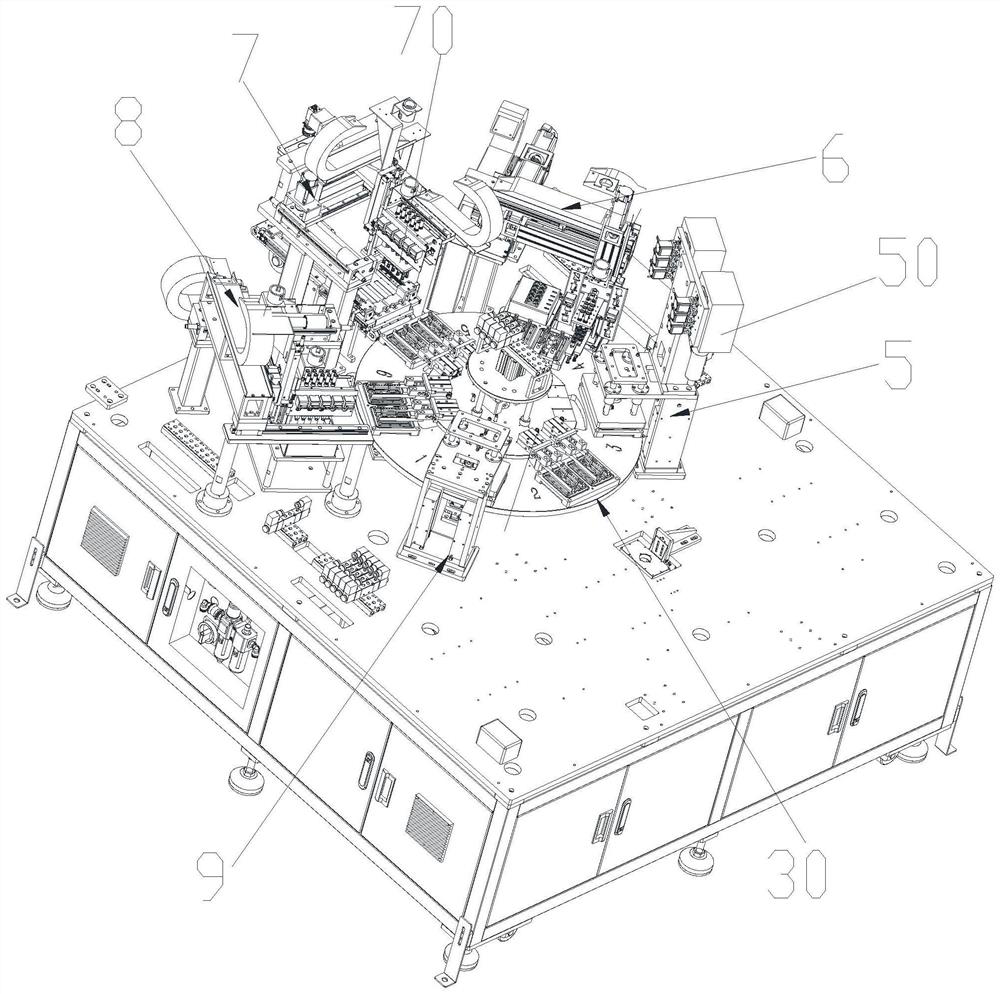

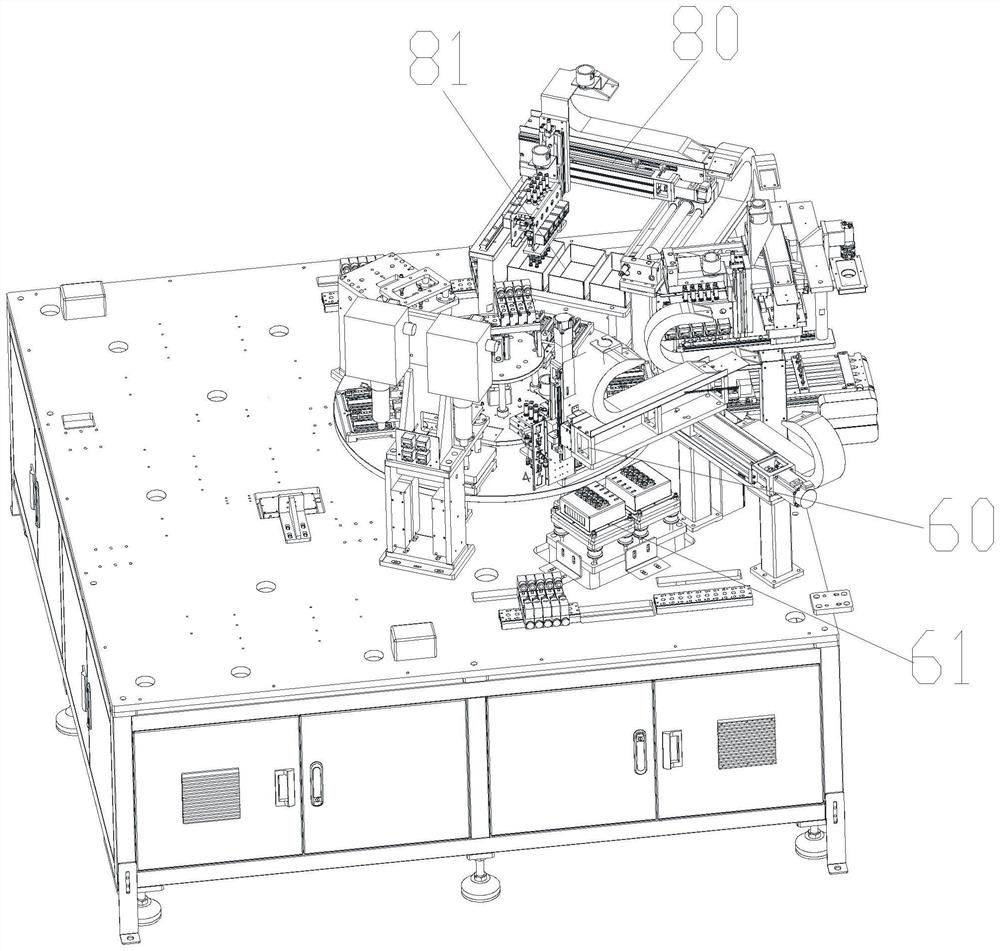

[0044] Please refer to the attached Figure 1-3, a battery leak detection and weighing device according to an embodiment of the present invention, comprising a feeding mechanism 1, a grabbing mechanism 2, a steering mechanism 3, and a receiving mechanism 4; Straight-line transmission, the battery placement tray 11 is in a rectangular shape, and the battery placement tray 11 is provided with battery accommodation chambers distributed in a mesh shape for placing multiple batteries 100; the material grabbing mechanism 2 is arranged above the feeding mechanism 1 There are six stations on the steering mechanism 3, and each station is provided with a carrier 30 for loading a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com