Needle modular assembly fixture based on textile machinery

A technology for assembling fixtures and textile machinery, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of sewing deviation of sewn products, affecting the normal processing of sewn products, affecting production efficiency and production quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

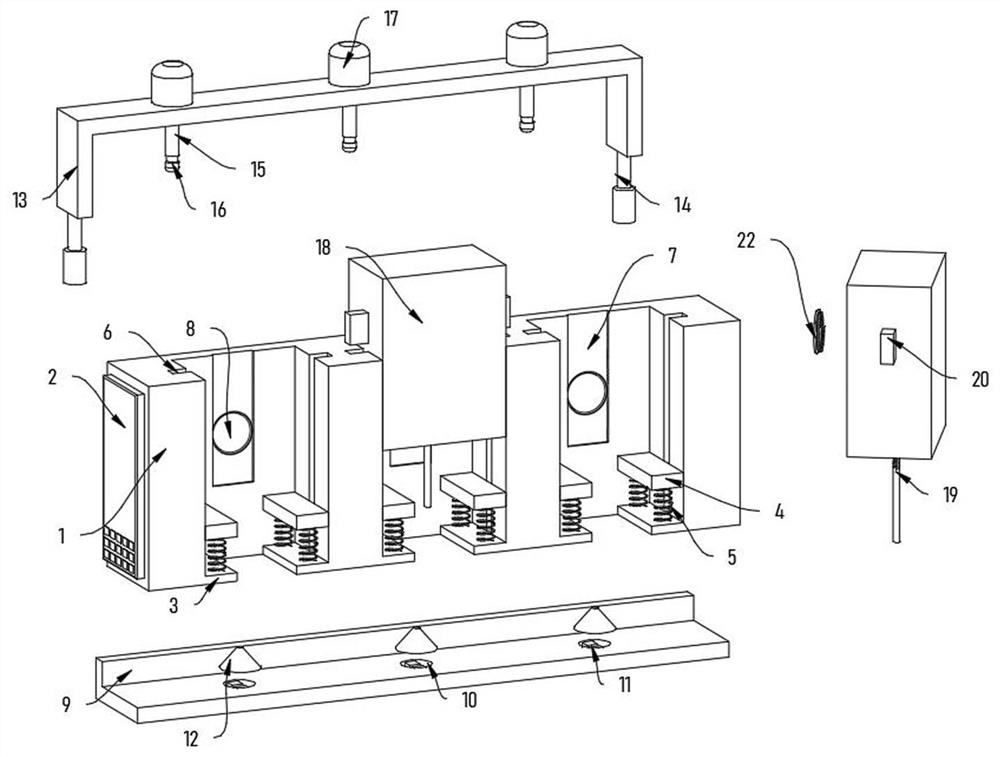

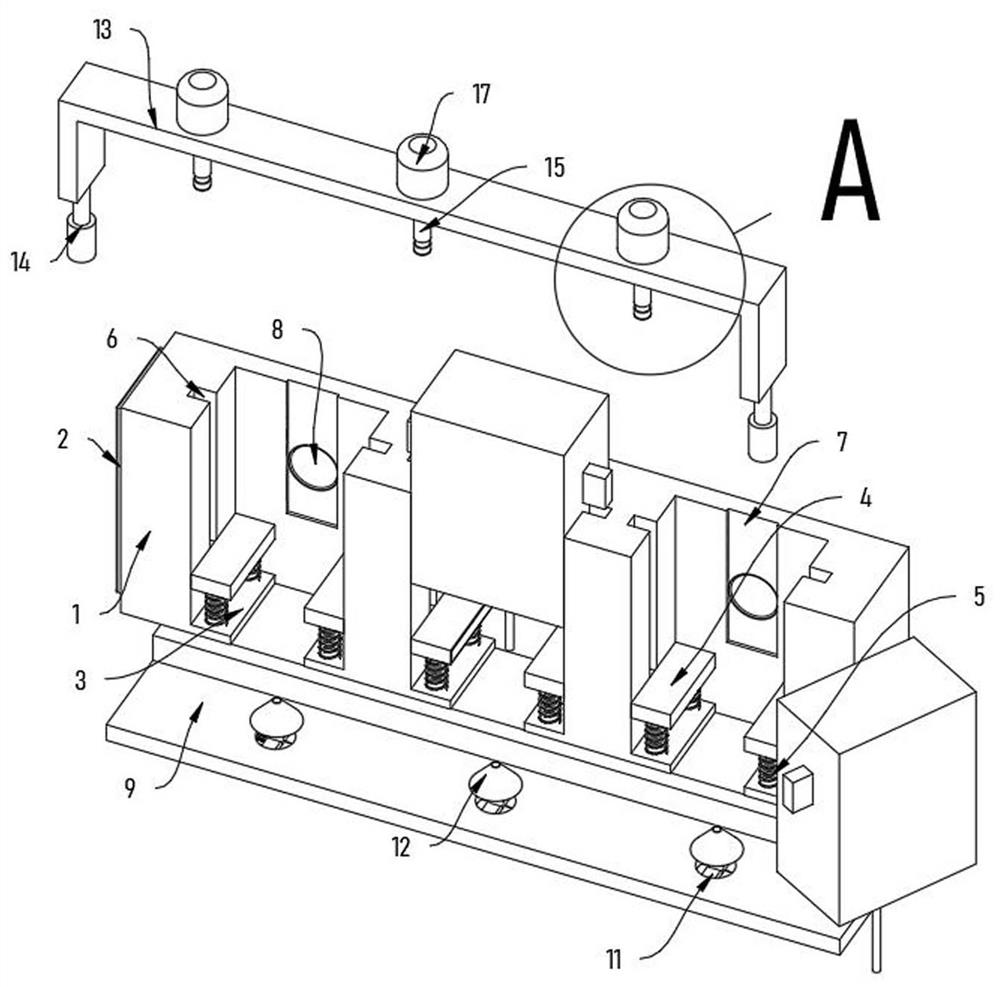

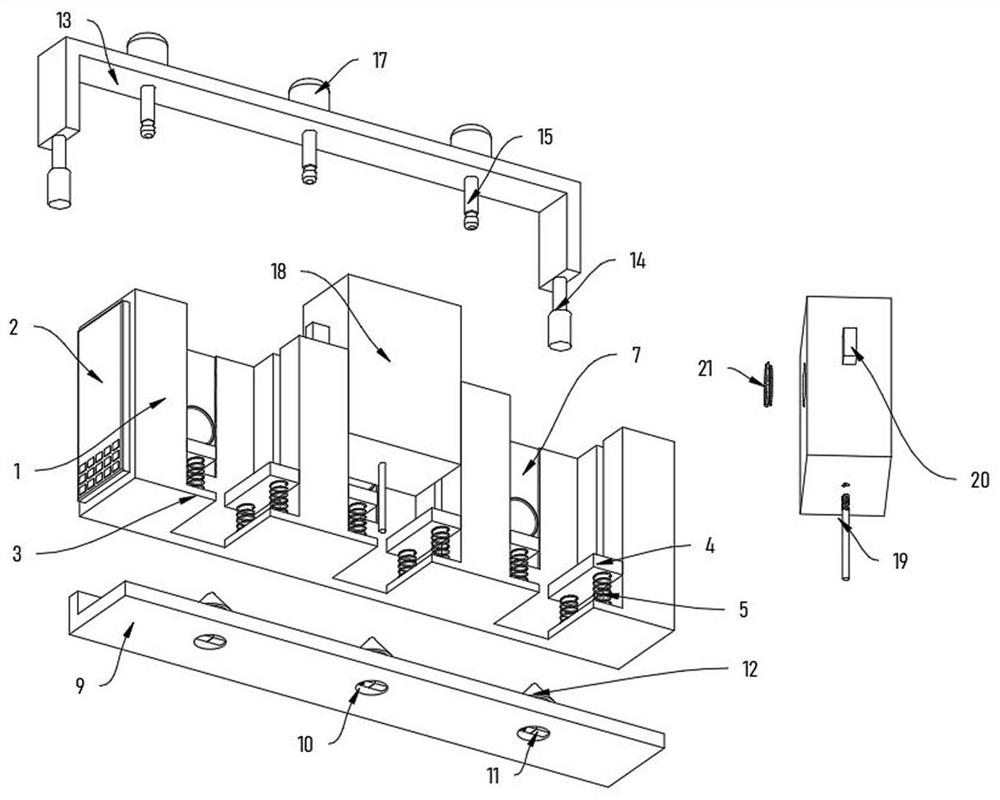

[0040] as attached figure 1 to attach Figure 10 Shown:

[0041] The present invention provides a needle modular assembly fixture based on textile machinery, including: a main body 1, refer to figure 1 , the inside of the main body 1 is provided with grooves in a linear array, the electromagnetic board 3 is fixedly connected to the bottom side of the left and right ends of a single groove, and the central controller 2 is also installed on the left end surface of the main body 1. The central controller 2 and the The electromagnetic board 3 is connected by wires, and the upper side of the electromagnetic board 3 is also elastically connected with the supporting plate 4 for carrying the module 18 through the return spring 5, and the induction sheet 22 installed on the rear side of the module 18 can be induced with the Unicom induction area 8, and The Unicom induction area 8 installed inside the main body 1 is a series structure, and synchronously, the needle 19 screwed on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com