Concrete point-by-point compacting device

A compact device and concrete technology, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of small coverage area of the movement path and uneven vibration, and achieve the effect of improving the coverage area and uniform vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

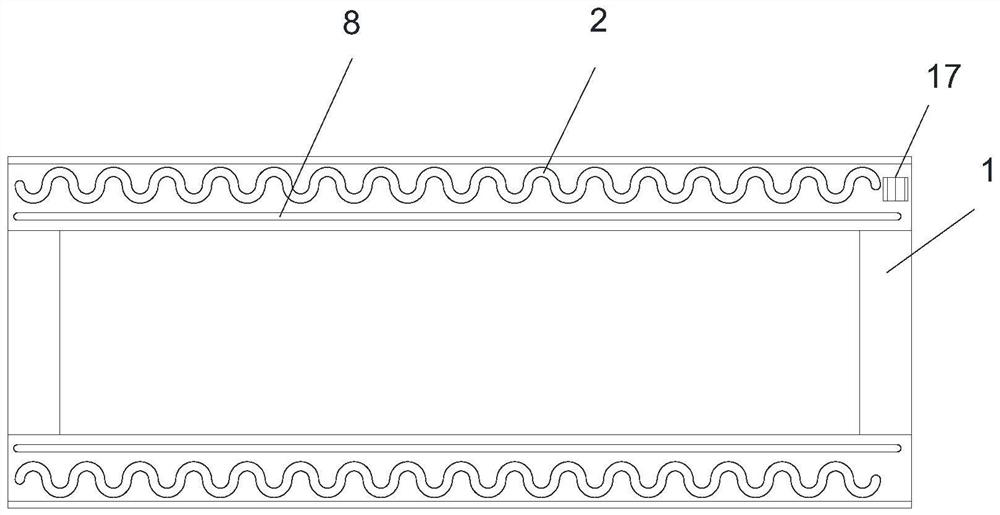

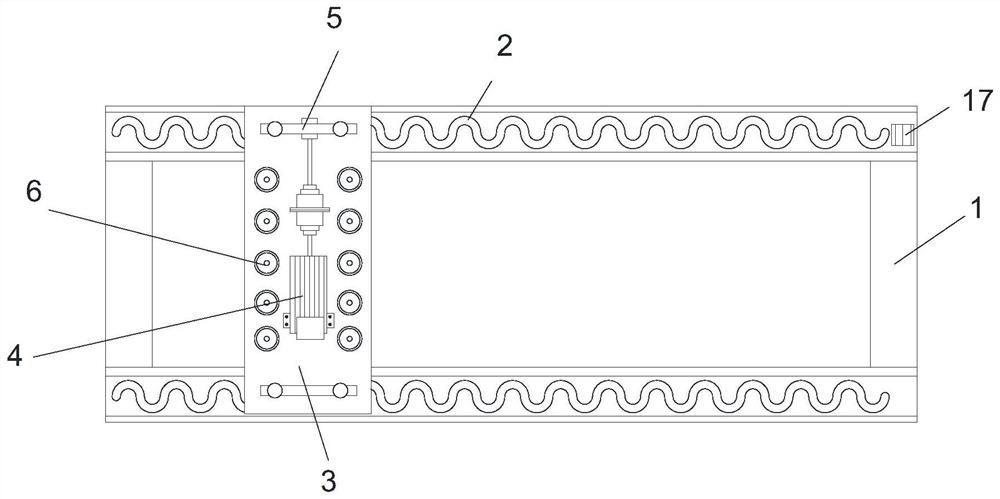

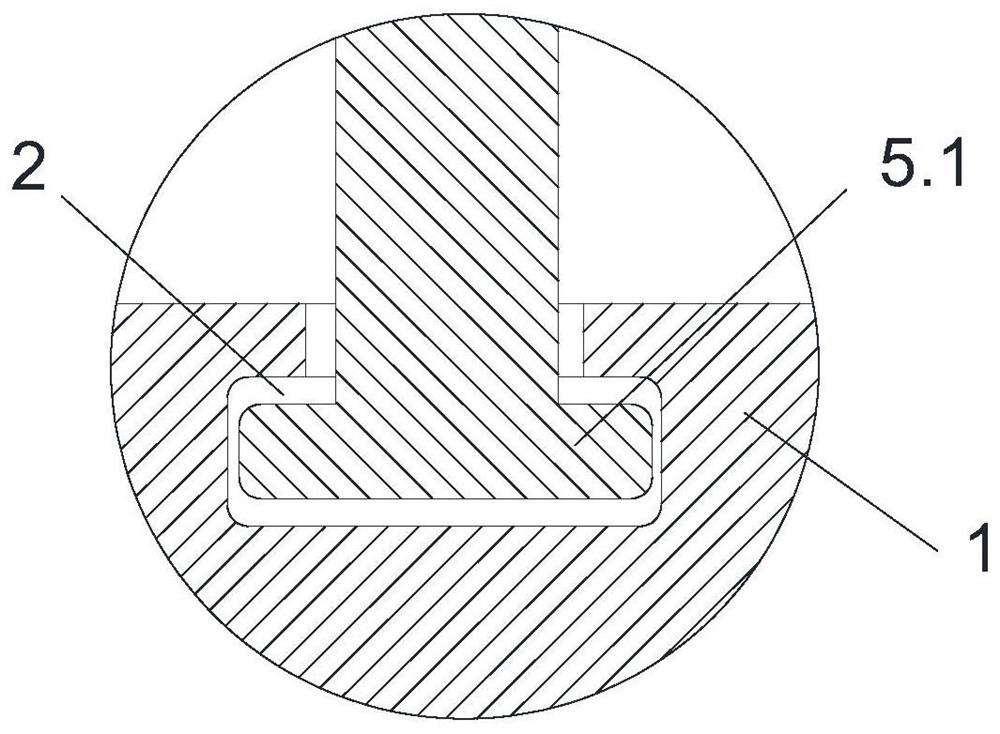

[0031] Such as Figure 1-9 As shown, a concrete point compaction device provided by the embodiment of the present invention includes a base frame 1 and a vibrating mechanism, the base frame 1 is provided with a wave-shaped guide groove 2, and the vibrating mechanism includes a support frame 3 The support frame 3 is provided with a power assembly 4, a walking assembly 5 and a plurality of vibrating assemblies 6, and the power assembly 4 drives the walking assembly 5 to walk with the support frame 3 guided by the guide groove 2 .

[0032] Specifically, the base frame 1 is used to support the vibrating mechanism, and the vibrating mechanism is movably connected on the base frame 1. The base frame 1 is different according to the type of the vibratin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com