Crane beam structure safety monitoring device with self-powered power supply

A technology for safety monitoring and crane beams, applied in measuring devices, material analysis by electromagnetic means, instruments, etc., can solve problems such as large workload, narrow space, covered dust, etc., to reduce monitoring costs, high accuracy, Easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

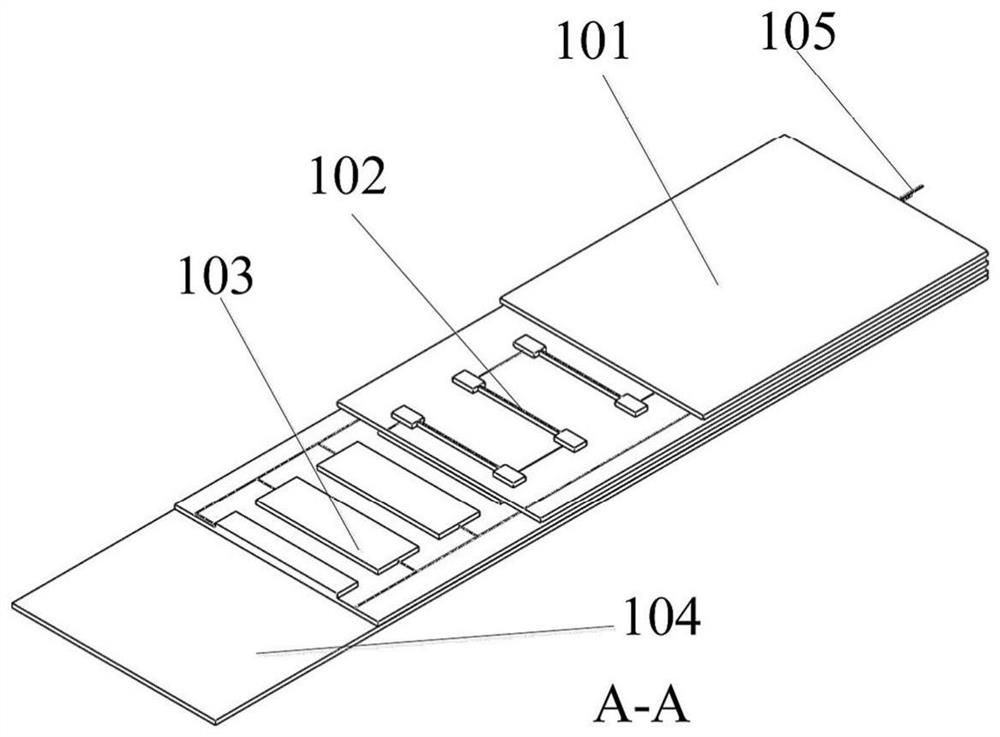

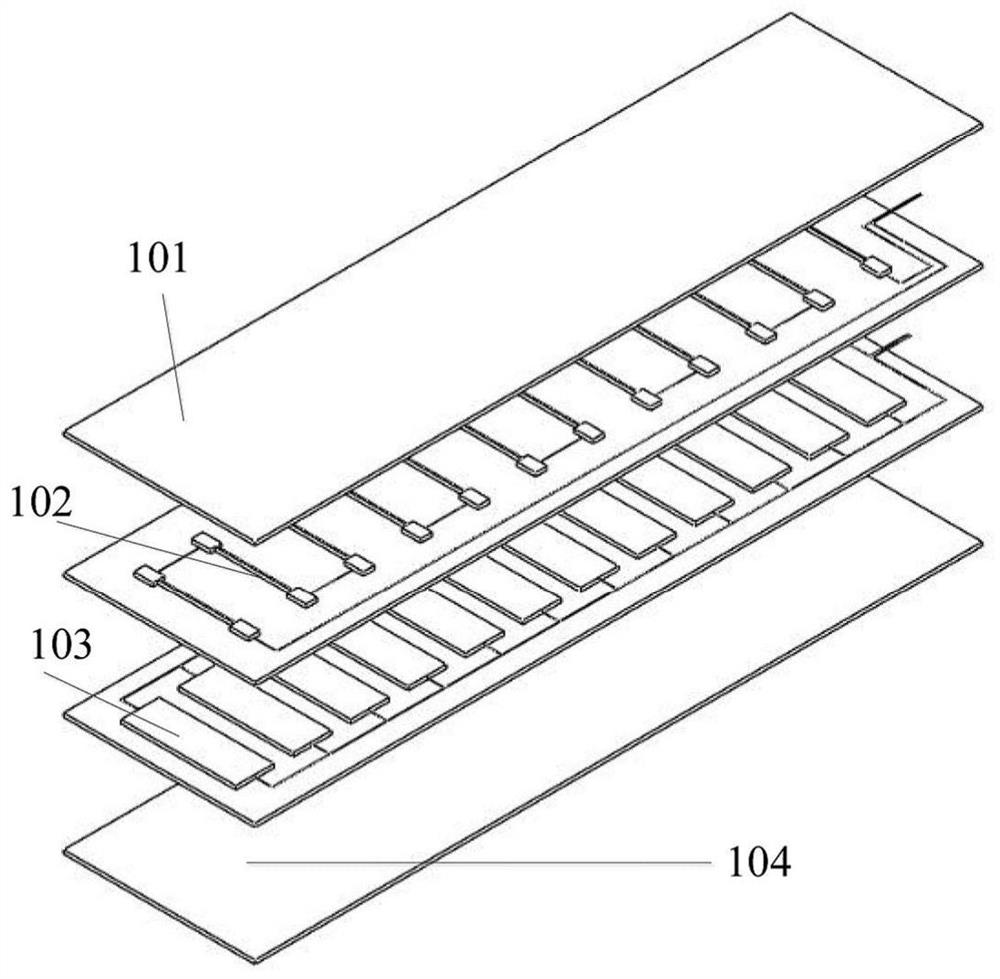

[0045] A crane beam structure safety monitoring device with a self-powered power supply, characterized in that it includes a crack sensor 1, a vibration power supply 2 and an automatic alarm 3, and the automatic alarm 3 is composed of a microcurrent measuring instrument 301 and a microprocessor 302 connected in sequence And a buzzer 303 and a warning light 304 are formed.

[0046] The crack sensor 1 is arranged on the surface of the structure to be monitored through special structural glue, and the output end is electrically connected to the micro-current measuring instrument 301; the vibration power supply 2 is based on structural vibration and uses electromagnetic induction to provide current, and is fixed on the middle and lower flange of the crane girder span , the output terminal is connected to the automatic alarm 3 and provides monitoring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com