A kind of commercial vehicle dryer control method

A control method and dryer technology, applied in the direction of brakes, vehicle parts, brake components, etc., can solve the problem that the dryer control method cannot adjust the degree of use of the dryer, etc., to achieve accurate application effects and ensure driving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with specific embodiment, the present invention is described in further detail:

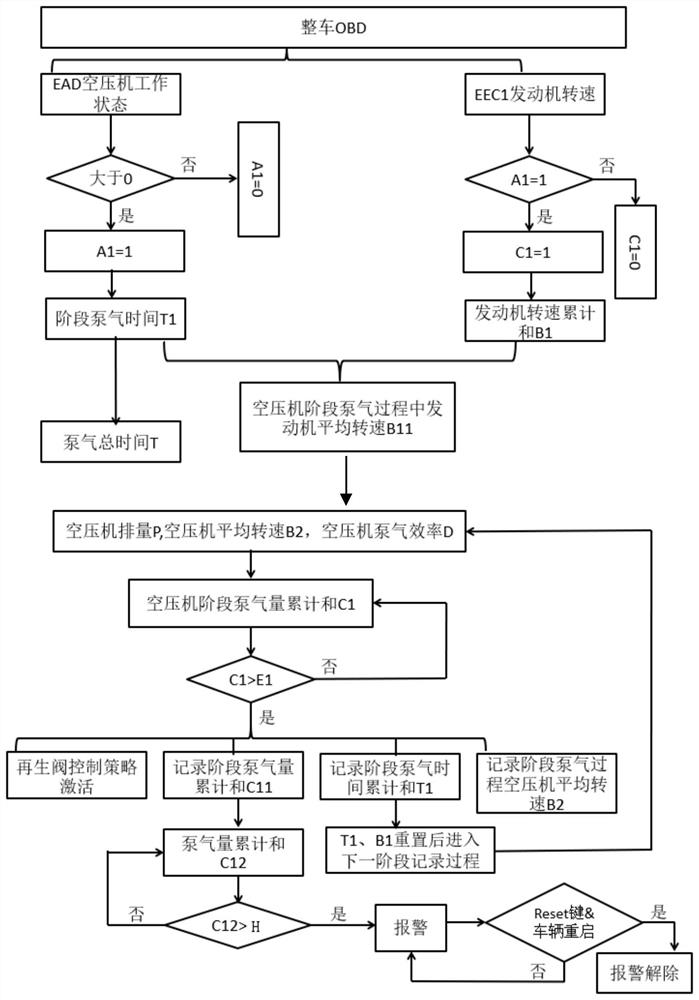

[0034] A commercial vehicle dryer control method, such as figure 1 shown, including:

[0035] S1. Turn on the drying tank replacement warning system;

[0036] S2. Obtain air compressor displacement information P and air compressor and engine transmission ratio information R, and record EAD-air compressor status information and EEC1-engine speed information through the vehicle CAN network;

[0037] S3. Perform algorithm control on the above data;

[0038] S4. Make a logical judgment on the cumulative sum of the pump air volume of the stage air compressor;

[0039] S5. After the accumulated air volume of the air compressor pump and C12 reach the warning set value H, the drying tank replacement warning system prompts the replacement of the drying tank;

[0040] S6. Operate the one-key recovery button to eliminate the alarm.

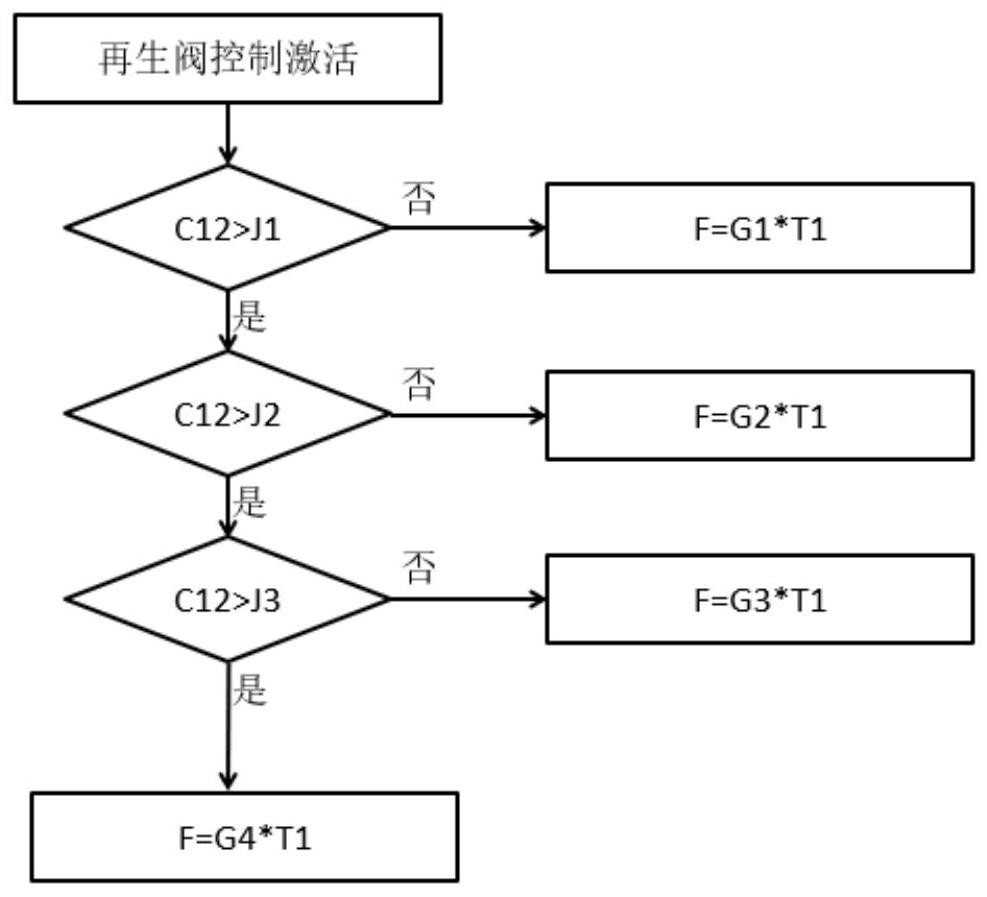

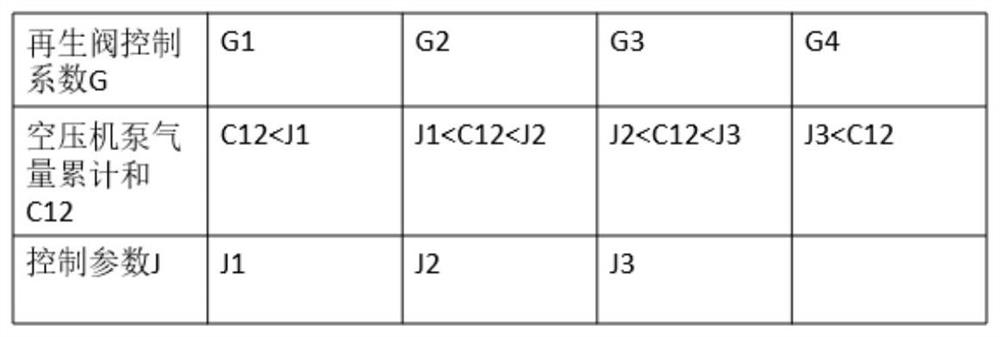

[0041] Step S3 includes:

[0042] S3.1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com