Torque measuring system special for butt-joint lock driving combination and in-situ calibration method

A technology of torque measurement and torque transmission, applied in the direction of force/torque/work measuring instrument calibration/testing, measuring device, torque measurement, etc. To achieve the stability of humidity and air pressure, prevent the effect of internal diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] A special torque measurement system and in-situ calibration method for a docking lock drive combination of the present invention will be described in further detail below in conjunction with the accompanying drawings.

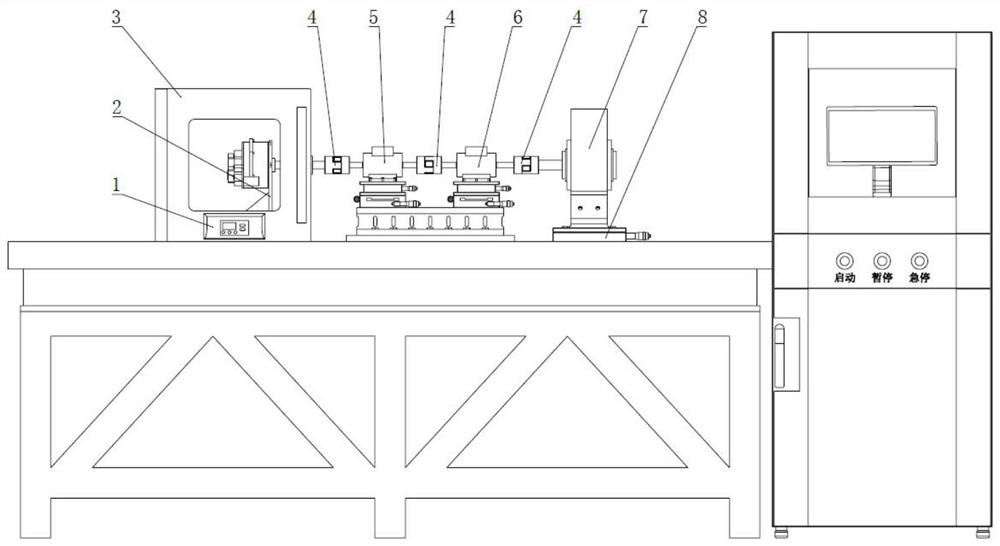

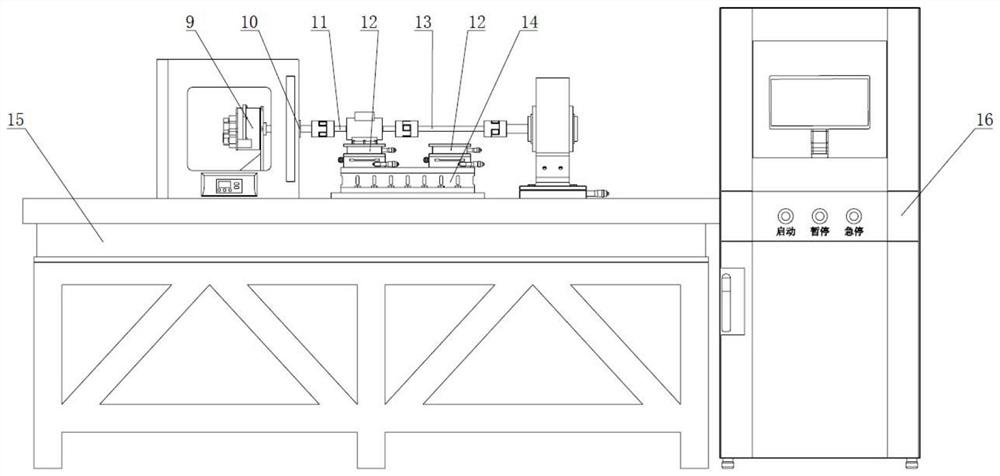

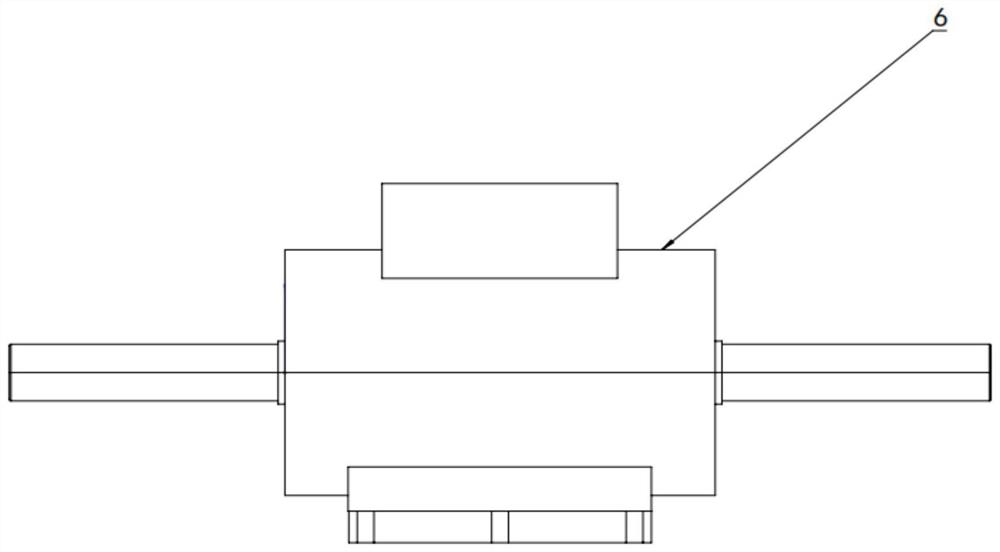

[0049] Such as figure 1 , figure 2 As shown, the I-shaped steel support base 14 in the present invention is fixed on the T-shaped groove experimental platform 15; the internal support frame 2 is fixed on the internal bottom plate of the high and low temperature environment controller 3, and is used to support the docking lock driving combination 9; The lock driving combination 9 is combined with the transmission shaft 11; the transmission shaft 11 passes through the high and low temperature environment controller 3 through the airtight bearing 10; the high and low temperature environment controller 3 is fixed on the T-slot experiment platform 15; the transmission shaft 11 passes through the shaft coupling The torque sensor 4 is connected with the torqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com