Special torque measuring device for lead screw connection combination and in-situ calibration method

A technology of torque measurement and lead screw, which is applied in the field of screw-connected combined torque measuring devices, can solve problems such as the inability to meet the ground test requirements of deep space exploration spacecraft, and achieve the effects of stabilizing environmental humidity and air pressure and preventing heat flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

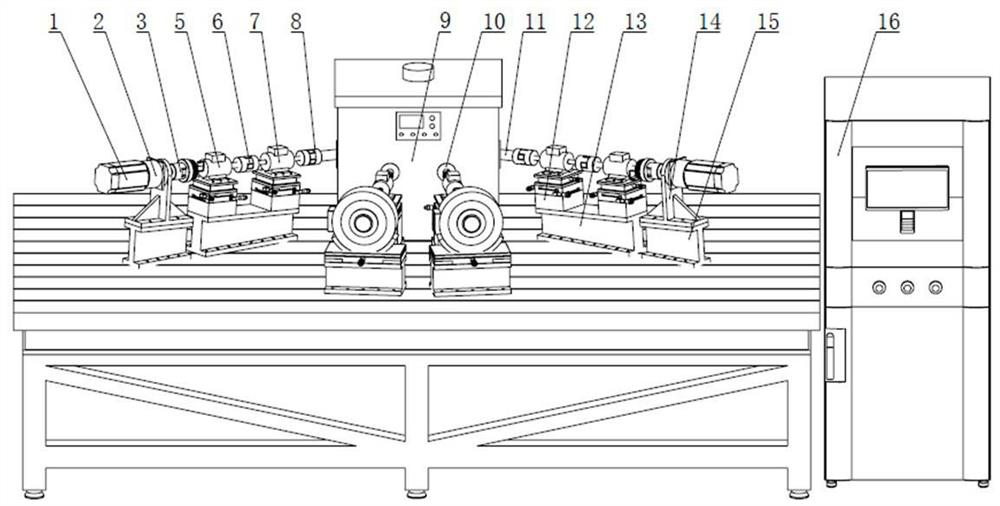

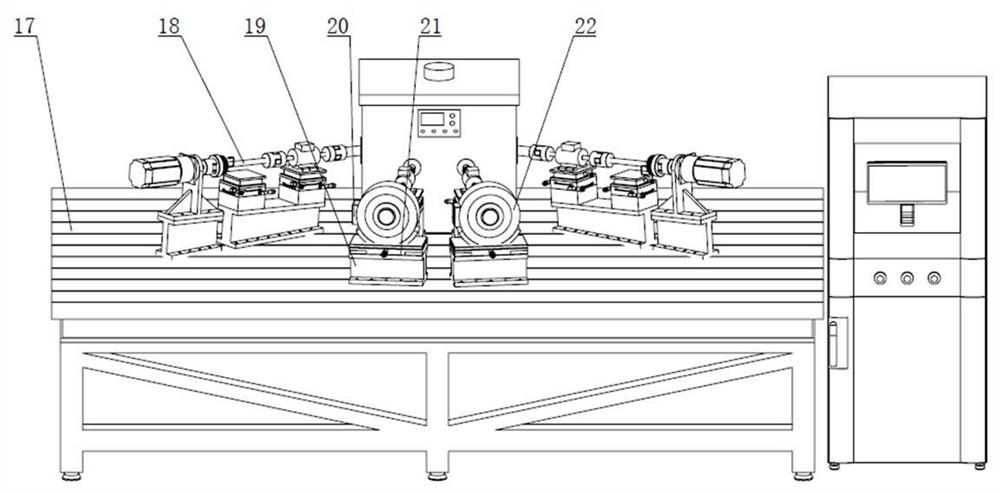

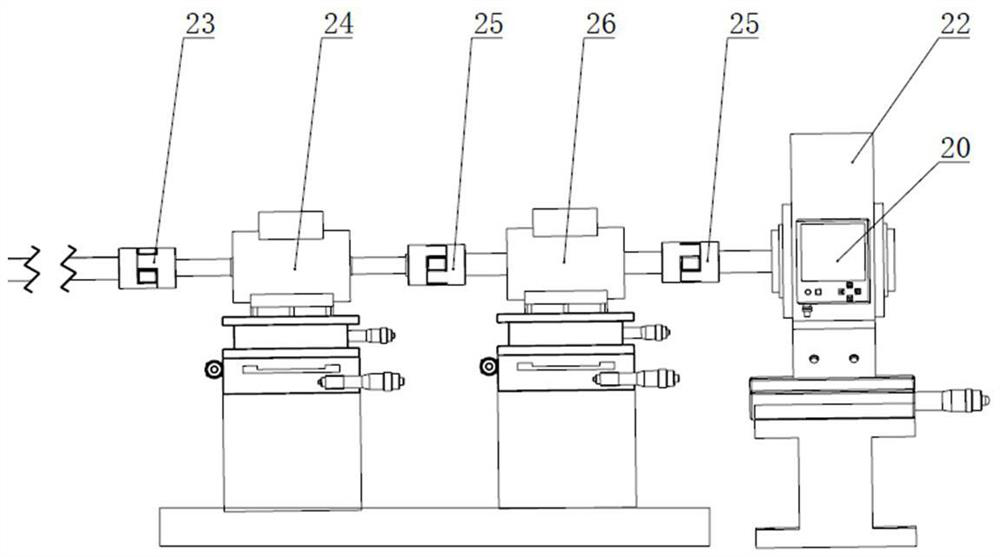

[0059] Such as figure 1 , figure 2 As shown, the extreme environment simulation module 9 is fixed in the center of the T-slot experiment platform 17 . Lead screws are installed on the left and right sides of the extreme environment simulation module 9 to connect the first shaft system and the second shaft system of the combined torque measuring device. The first shaft system and the second shaft system of the screw connection combined torque measuring device both include a servo motor 1, a planetary reducer 2, a torque limiter 3, a first standard torque sensor 5, a first sensor coupling 6, The first torque speed sensor 7 and the first lead screw are in contact with the combined shaft coupling 8 .

[0060] The motor reducer support frame 15 is fixed on the T-slot experimental platform 17 for supporting the reducer support frame 14; the reducer support frame 14 is used for supporting the servo motor 1 and the planetary reducer 2; the servo motor 1 and the planetary reducer M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com