Dough pressing adjusting device of full-automatic noodle rolling equipment and working method

An adjusting device and fully automatic technology, applied in the direction of dough extruder, etc., can solve the problems such as the failure of the dough to form, the falling of the dough, and the high labor intensity, and achieve the effect of stable fixed position and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

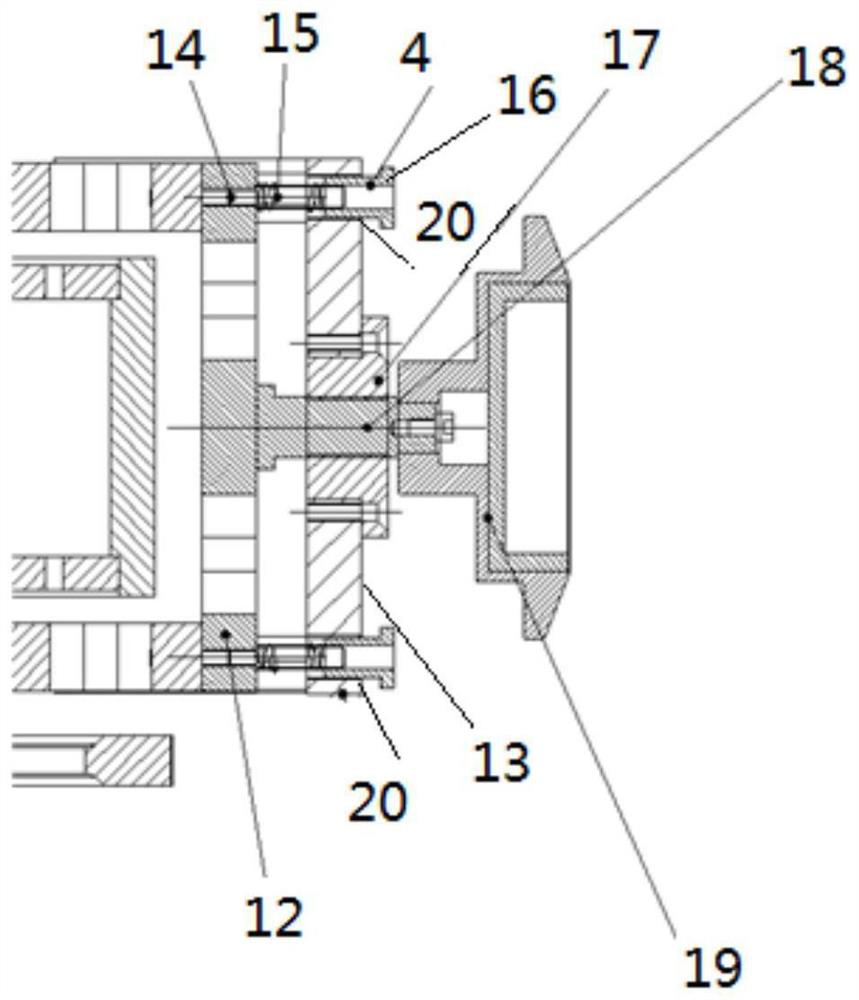

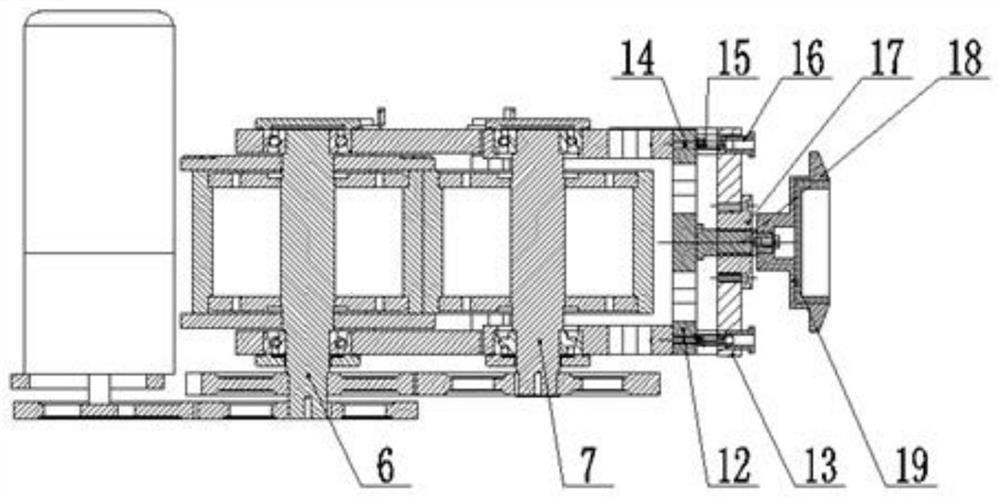

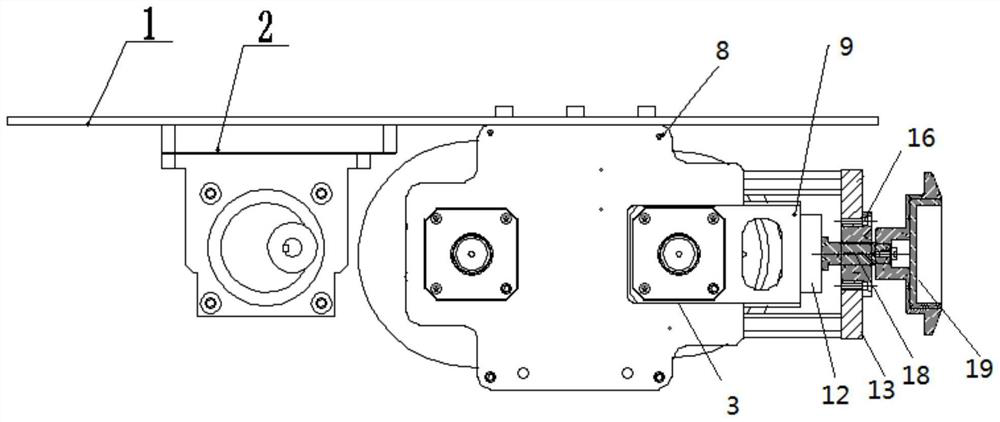

[0028] The present invention is a kind of pressure surface regulating device of automatic rolling noodle equipment, such as figure 1 , including: a positioning plate 12, a fixed plate 13 and a sliding bearing seat 9; the positioning plate 12 and the fixed plate 13 are vertically arranged, and are arranged at intervals in the axial direction, and are parallel; between the positioning plate 12 and the fixed plate 13 Equipped with retractable device.

[0029] The above-mentioned sliding bearing seat 9 is arranged on the front end of the positioning plate 12, its rear end is connected with the positioning plate 12, and its front end is used to connect with the driven noodle roller 7, which can slide back and forth in the axial direction ; The front end of the driven noodle roller 7 is provided with an active noodle pressing roller 6, and in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com