Inclined platform, substrate conveying device and substrate conveying method

A technology of transmission device and transmission method, which is applied in the direction of transportation and packaging, conveyors, rollers, etc., can solve the problems of excessive etching on the substrate surface, affect the substrate transmission efficiency, and limit the substrate transmission size, so as to improve product quality and maintain product quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

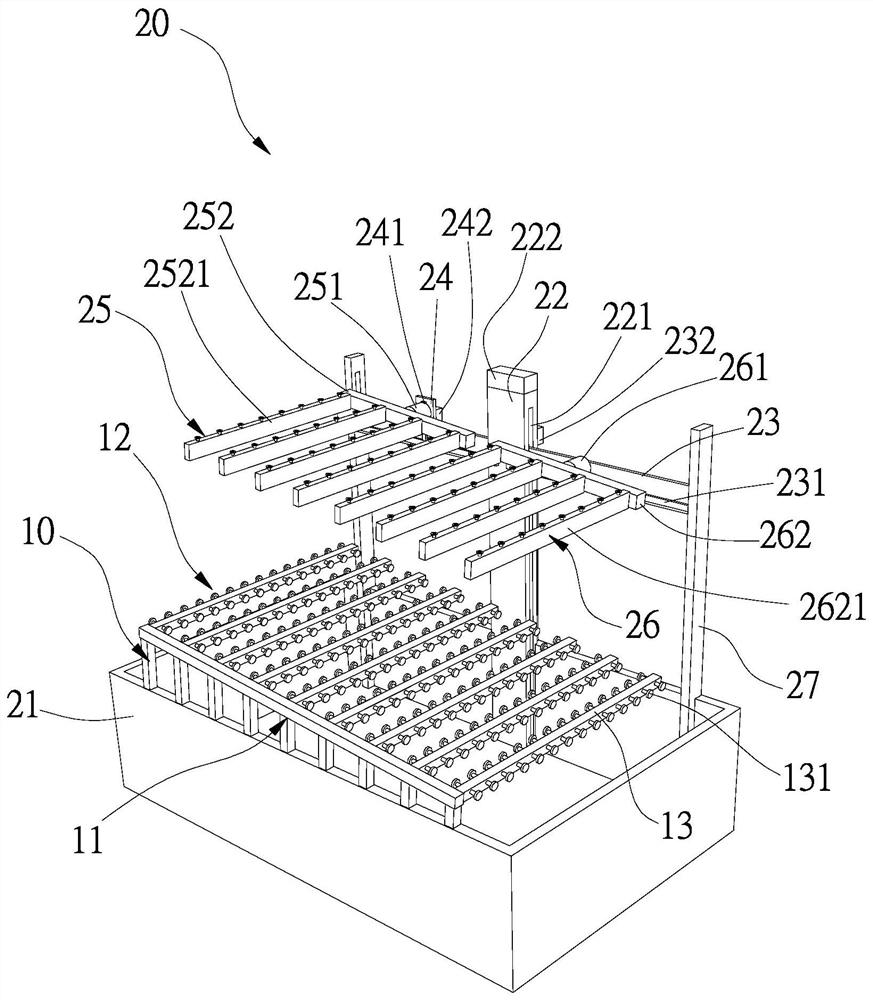

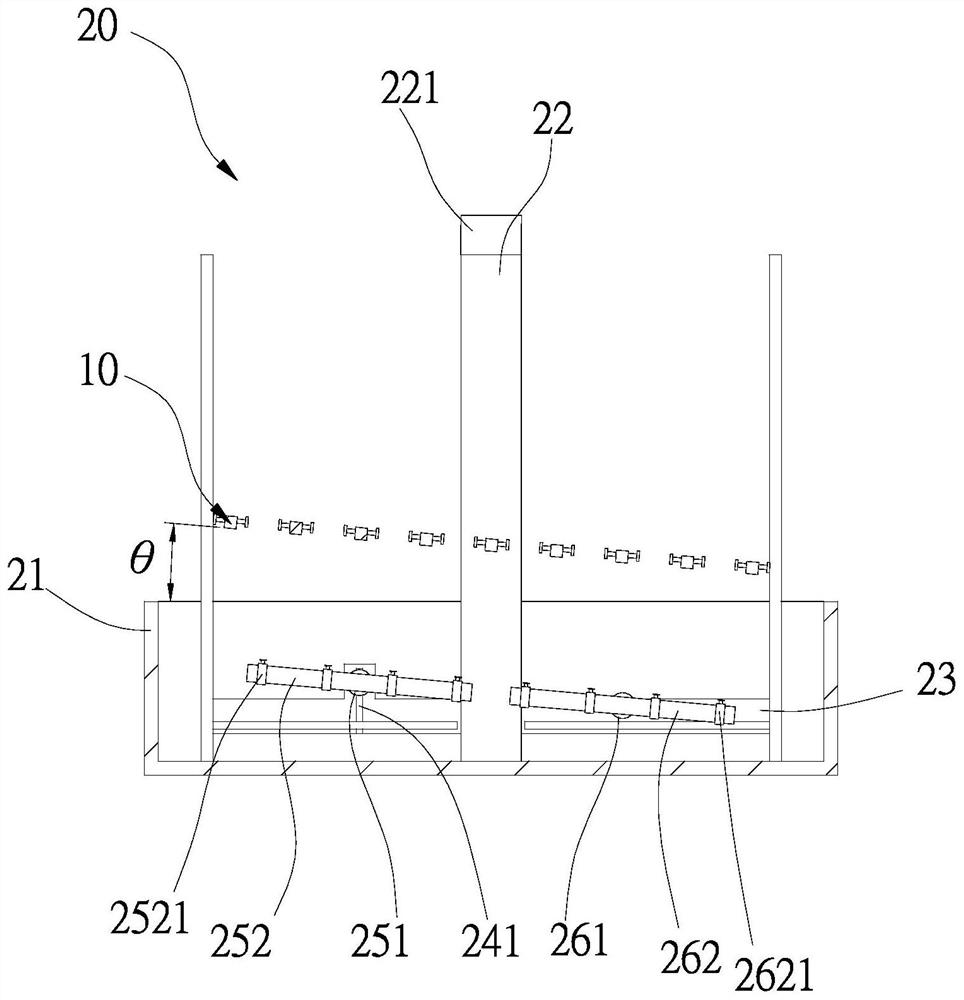

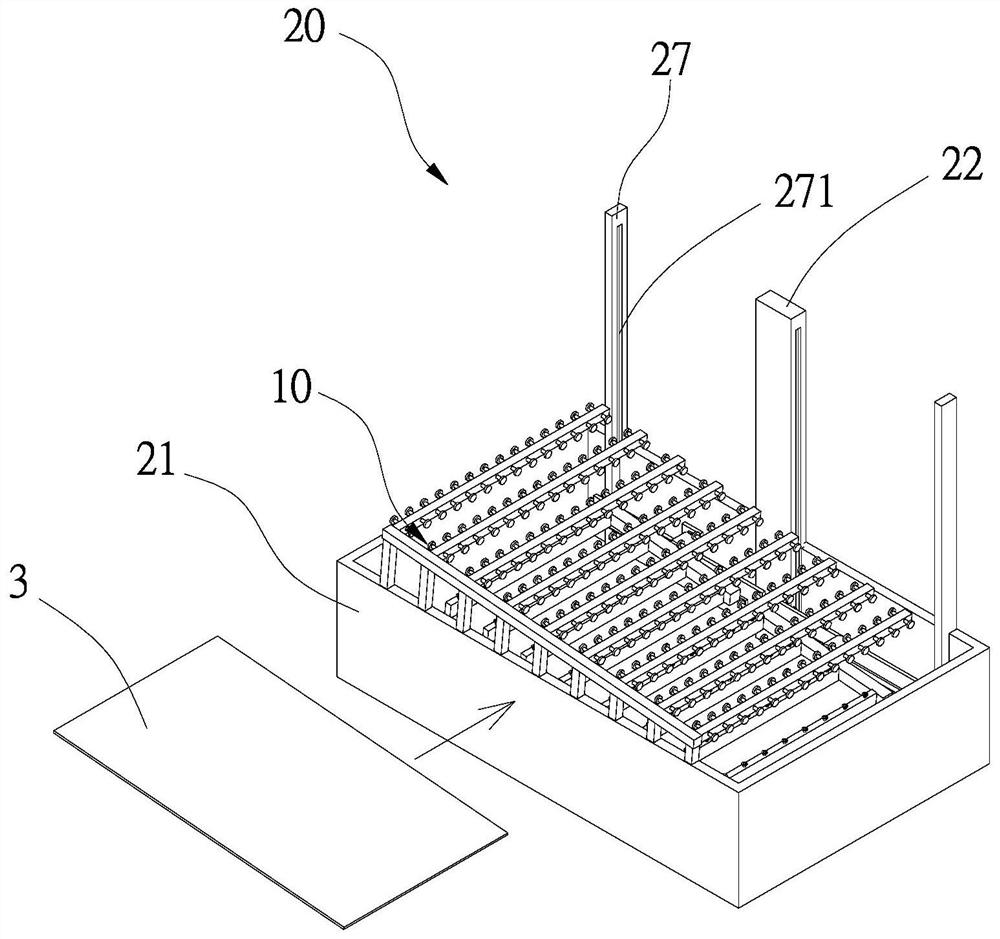

[0094] First, see figure 1 and figure 2 As shown, it is a perspective view of the overall device and a cross-sectional view of the overall device of a preferred embodiment of the substrate transfer device of the present invention, wherein the inclined platform 10 of the present invention is suitable for the substrate transfer device 20, wherein the substrate transfer device 20 includes at least one base Seat 21, which mainly lies in that: the inclined platform 10 is set on the base 21, and an included angle θ is interposed between the inclined platform 10 and the base 21, wherein the included angle θ is between 3 degrees and 10 degrees Between, preferably 5 degrees, that is to say, the inclined platform 10 is erected on the upper surface of the base 21 by a plurality of conveying rollers 13 of unequal height, so that the long side 11 on the left side of the inclined platform 10 Higher than the long side 11 on the right side, and the upper surface of the inclined platform 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com