Camellia seed screening mechanism for camellia oleifera processing

A technology of oil camellia seeds and strengthening mechanism, which is applied in the directions of separating solids from solids by air flow, sieving, solids separation, etc., can solve problems such as poor screening effect, and achieve good processing quality, small space occupation, and efficient shaking. The effect of the sieving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

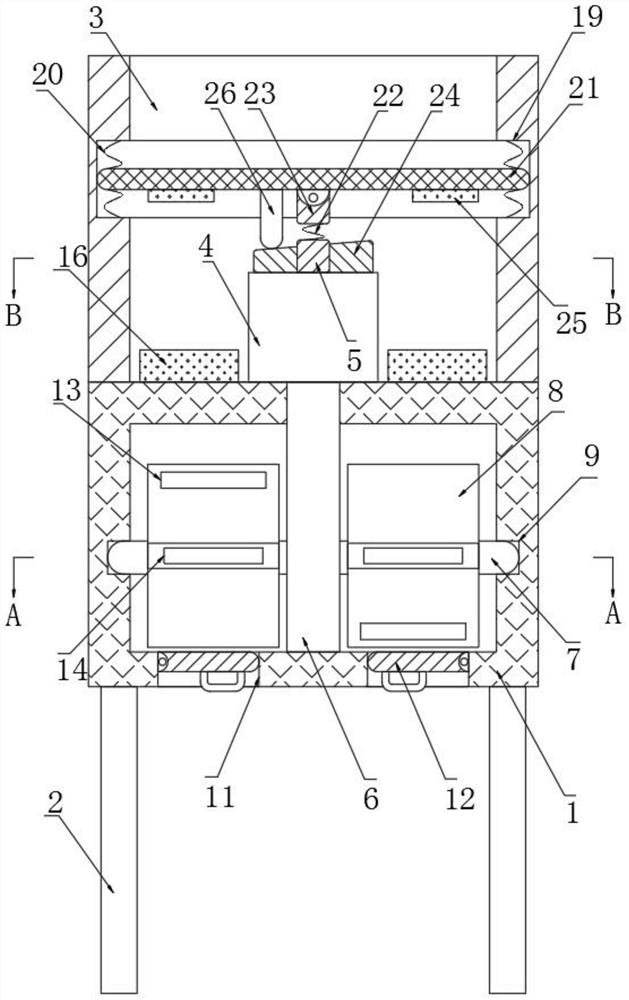

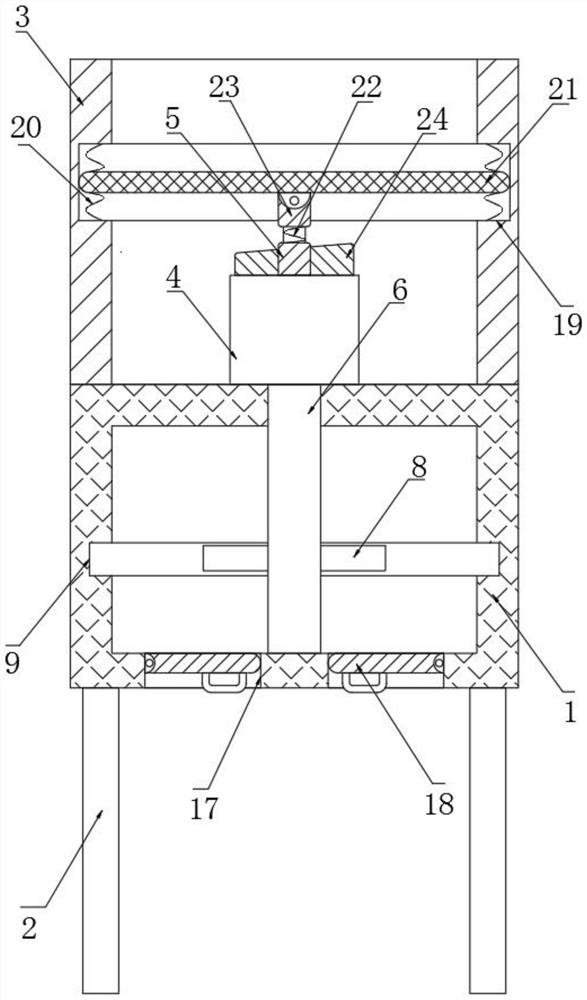

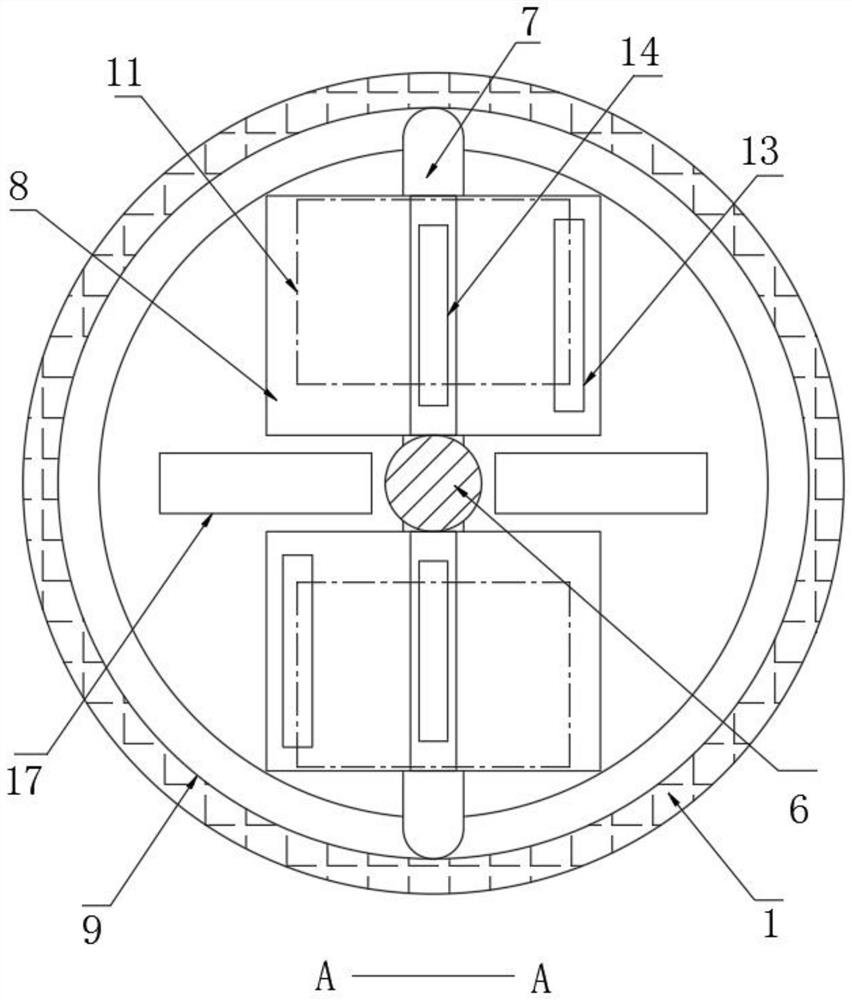

[0023] refer to Figure 1-6 , a Camellia oleifera seed screening mechanism for processing, comprising a subdivision box 1, a bracket 2 is fixed on the bottom of the subdivision box 1, a coarse sieve box 3 is fixed on the upper end of the subdivision box 1, and the inside of the coarse sieve box 3 is provided with Coarse screening mechanism, motor 4 is fixed on the top of subdivision box 1, lower shaft 6 is fixed on the output shaft at the lower end of motor 4, the side wall of lower shaft 6 is provided with multiple groups of fine screening mechanisms, and the upper end of subdivision box 1 runs through A plurality of transfer grooves 10, the bottom of the subdivision box 1 is provided with a plurality of concentration grooves 11 and a plurality of independent grooves 17, and the inside of each concentration groove 11 is connected with a concentration cover plate 12 by torsion spring rotation, and each independent groove 17 The interior is connected with an independent cover p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com